Product Description

Two-Piece Split Ring Bearing Specifications

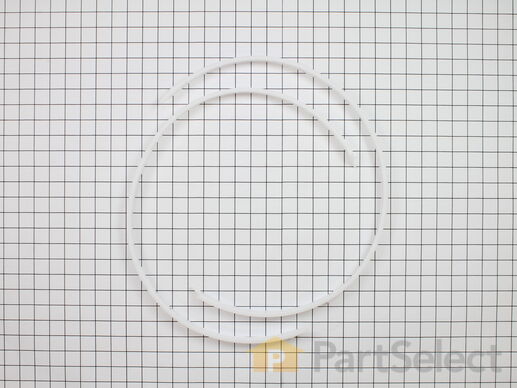

This is a replacement bearing ring kit for your dryer. The bearing rings are found on the top and bottom lips of the dryer drum. If your dryer is unusually noisy, or the drum will not turn during operation, or if there are marks left on your clothes after a cycle, you may need to replace the bearing ring kit. The kit comes with 2 bearings, one for the top and one for the bottom of the dryer drum. Remove the front panel of your dryer to access the dryer drum for this repair. At this point you can use a pair of needle nose pliers to release the old bearing rings from the drum. Snap the new bearing rings on, and reassemble the dryer to complete your repair.

How Buying OEM Parts Can Save You Time and Money

Part Videos

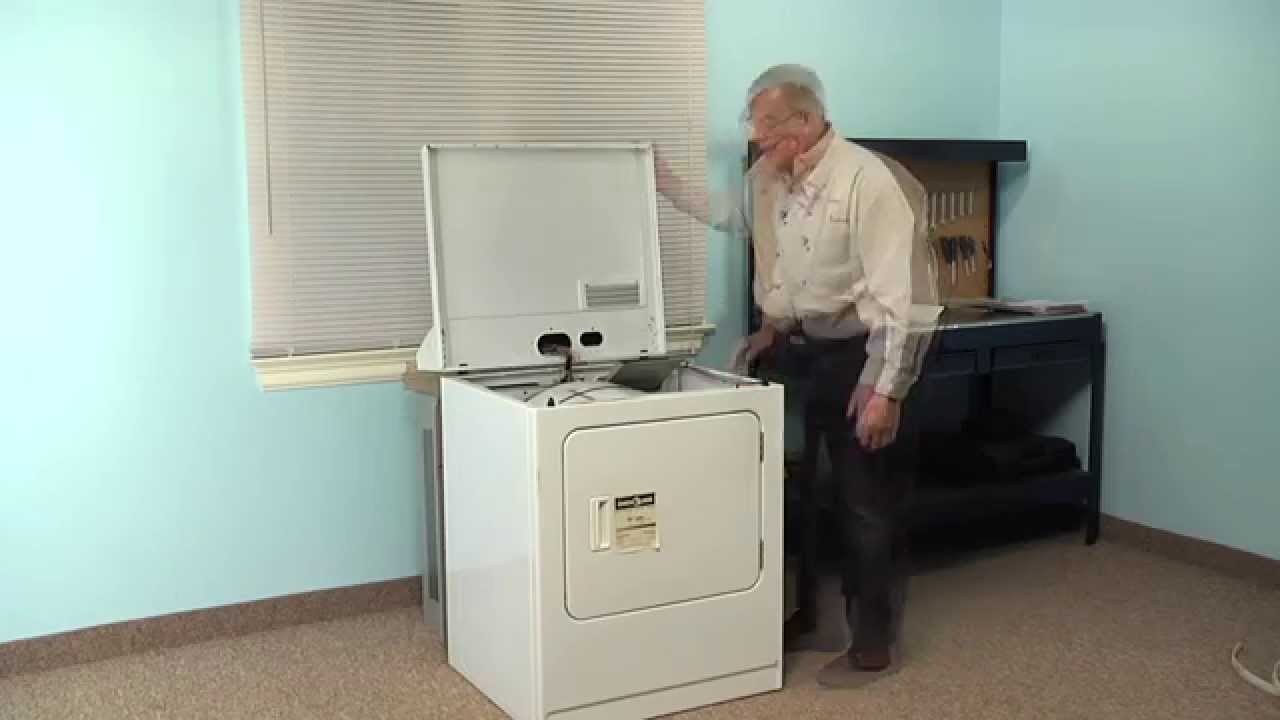

Replacing your Whirlpool Dryer Two-Piece Split Ring Bearing

Troubleshooting

This part fixes the following symptoms:

Noisy | Marks left on clothes

This part works with the following products:

Dryer.

This part works with the following products:

Whirlpool, Kenmore, KitchenAid, Maytag.

Part# 279441 replaces these:

AP2996731, 2683, 279441, 279441, 692526

Customer Reviews

Filter By Rating:

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Joey L - 8 days ago

Verified Purchase

Worked perfect

Part fit 100% and was an easy install.

David J - 18 days ago

Verified Purchase

Easy repair

It’s good part I receive and dryer is working perfectly fine again ,thanks to parts select

Melvyn C - May 18, 2023

Verified Purchase

great part

arrived with in 2 days and working with the video was a great help

Kevin O - January 18, 2023

Verified Purchase

fast shipping, easy to fix

My part was shipped very quickly and was easy to install.

Daren D - August 13, 2021

Verified Purchase

Worked good, easy to install.

The complete ring was in the package for me, top and bottom part, snapped in fast.

Manuel P - November 9, 2019

Verified Purchase

Easy to install

The replacement part fitted perfectly and extremely easy to install

- < Prev

- 1

- Next >

Customer Repair Stories

Average Repair Rating: 2.9 / 5.0, 11 reviews.

What's this?

- < Prev

- 1

- 2

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Dryer was sqeaking loudly when running

I Looked on internet sites for this type of problem.

Most sites said the support rollers could cause this.

I found your site PartSelect and with help of your diagrams of the machine ordered the parts I thought were needed plus other parts that might cause the problem.

With machine torn down I replaced the rollers.

I had also ordered the main drive belt and idler assembly with the rollers and these also needed replacement. It is a good idea to order other suspect parts when doing this type of repair since you can return the parts not needed.

Your return policy is great.

Edward Brennan

Most sites said the support rollers could cause this.

I found your site PartSelect and with help of your diagrams of the machine ordered the parts I thought were needed plus other parts that might cause the problem.

With machine torn down I replaced the rollers.

I had also ordered the main drive belt and idler assembly with the rollers and these also needed replacement. It is a good idea to order other suspect parts when doing this type of repair since you can return the parts not needed.

Your return policy is great.

Edward Brennan

Other Parts Used:

-

Edward from Andover, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

124 of 146 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer sounded like it had rocks in it when running

Following the instructions that came with the parts, I removed the top off of the dryer, which was very easy, two more 5/16" screws and I had the drum out. I confess, this was my second time at this repair. 1st time I neglected to replace the rear drum seal which I strongly recommend you do while you have it open. I only replaced the 2 wheels last time and it failed very soon afterwards.

Lesson Learned: Always replace the rear drum seal when you replace the support wheels!!!

Lesson Learned: Always replace the rear drum seal when you replace the support wheels!!!

Other Parts Used:

-

Mark from Kirkwood, MO

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

33 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor tried, but could not turn drum

First, I unplugged it and pulled it away from the wall. Then I pryed the front of the top up. It is scary to apply that much force, but the clips did not break. It opens like a car hood. Then I removed the two sheet metal screws that hold the front to the sides. Don't forget to unplug and unclip the door switch wires. Then I lifted the front off the bottom clips. Be sure to hold the drum up when you do this. Three hands will make it easier. Then remove the drum and belt. The belt tensioner will fall off, but that is ok.

I thought the problem would turn out to be the motor, but instead it was the front seal for the drum. It is felt and had broken. It folded under itself and was jamming the drum to the point that the motor couldn't turn it.

I replaced the felt seal, which attaches to the front cover with three clips and also replaced the plastic guides, which clip to the drum. Both were easy to do. I had replaced the rear drum seal a few years ago and so it was ok, otherwise I would recommend doing that too.

While I had it apart, I opened up the back and cleaned out all the lint in the fan housing. I had replaced the heater element, thermal switch and fuse a few years ago, so they were fine.

I also replaced the mosture sensor, just because it only cost $11. I bought a new lint filter, because it had holes in it after 20 years. I replaced the belt, because it was only $10. I replaced the lint filter cover and front door handle, because they had yellowed. I will warn you about the front door handle. It was a bear. I finally had to take the door apart to get the little plastic clip to seat correctly.

Then I put it all back together, which again is easier with 3 hands. Holding up the drum and putting the front cover on the lower clips can be a bit tricky alone. Also, be sure to rotate the drum to make sure the rear seal is not folded under and the front seal is seated correclty.

I fired it up and it ran great, except for the constant whistling. I had wondered what the little clear plastic box in the back did. Turns out it is the lint filter is full whistle warning thing. I took the back off again and found a wire was resting on the flapper door of the box and holding it in the wrong postion. By the way, it is a really irritating sound after the first few minutes. I moved the wire and it works great.

I worked slowly and it went well and was not hard.

I thought the problem would turn out to be the motor, but instead it was the front seal for the drum. It is felt and had broken. It folded under itself and was jamming the drum to the point that the motor couldn't turn it.

I replaced the felt seal, which attaches to the front cover with three clips and also replaced the plastic guides, which clip to the drum. Both were easy to do. I had replaced the rear drum seal a few years ago and so it was ok, otherwise I would recommend doing that too.

While I had it apart, I opened up the back and cleaned out all the lint in the fan housing. I had replaced the heater element, thermal switch and fuse a few years ago, so they were fine.

I also replaced the mosture sensor, just because it only cost $11. I bought a new lint filter, because it had holes in it after 20 years. I replaced the belt, because it was only $10. I replaced the lint filter cover and front door handle, because they had yellowed. I will warn you about the front door handle. It was a bear. I finally had to take the door apart to get the little plastic clip to seat correctly.

Then I put it all back together, which again is easier with 3 hands. Holding up the drum and putting the front cover on the lower clips can be a bit tricky alone. Also, be sure to rotate the drum to make sure the rear seal is not folded under and the front seal is seated correclty.

I fired it up and it ran great, except for the constant whistling. I had wondered what the little clear plastic box in the back did. Turns out it is the lint filter is full whistle warning thing. I took the back off again and found a wire was resting on the flapper door of the box and holding it in the wrong postion. By the way, it is a really irritating sound after the first few minutes. I moved the wire and it works great.

I worked slowly and it went well and was not hard.

Other Parts Used:

-

Chris from Worcester, MA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

29 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer motor would 'kick out' when starting up.

Unplugging the dryer and opening the front was just 2 screws and 2 bolts. I found the rear drums felt gasket was torn and folder over. This was pulling the drive motor down until it kicked out. So I removed the drum from the dryers housing and placed it on the floor. With a pliers gripped the felt and pulled it from the drum. With sand paper I cleaned the remains and then used clothe pins to hold the new gasket in place so I could glue it back onto the drum. After 5 minutes I removed the pins and remounted the drum. Using a butter knife to guild the felt from folding over, I turned the drum by hand once to ensure proper movement. The entire repair was done in 27 minutes alone.

Other Parts Used:

-

Phillip from Austin, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

14 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would run with no heat

I watched all the videos with Steve. He was very helpful in his presentation of the repairs. Due to the age of the dryer every thing was replaced and was very easy to do. Thank you Steve and PartSelect for making these repairs possible and easy

Other Parts Used:

-

Gary from MOUNDSVILLE, WV

-

Difficulty Level:Very Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

8 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

loud shrieking sound when it ran

nobody has said it yet so... to take a dryer apart, take the back off, pull the lint trap, remove two screws on back of the top piece. the whole top shifts forward and disengages two clips on front corners, it then tilts up and back. the front comes off next, this frees up the tub. all parts ordered replaced worn parts, though there was no smoking gun as to the source of the sound. once it was apart, it was a cakewalk. had it up and running in 45 minutes. can't see how it took others two hours.

Other Parts Used:

-

john from appleton, WI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

4 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The dryer tub became jammed, unable to turn.

I followed disassembly directions found on youtube and replaced th two-piece ring bearing that was identified by a parts diagra fron PartSelect. The repair was easy. Fix time was about thirty mionutes.

Other Parts Used:

-

Terry from Lindsay, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not run. Push start and only relay clicked.

Troubleshoot wiring to make sure it was'nt fuse or limit switchs. Had voltage to motor but nothing happened. Had to be the motor. Ordered motor and a couple of other parts that needed to be replaced. Motor replacement was real easy, hardest part for me was getting blower off motor shaft. Was a good time to clean out dryer and vent.Found a few dollars in lost change also, my tip. Used your regular shipping and from order to repair was only three days. I would definitly order from you again. Thanks.

Other Parts Used:

-

Charles from Traverse City, MI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Wrench (Adjustable)

3 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My old dryer drum had become noisy and loose and prone to getting stuck while running.

I replaced the front seal and bearing, split ring bearing and rear seal. It was technically pretty easy. The thing to do is watch the videos provided by PartsSelect AND go to Youtube and watch a couple of others. Once you see several guys do the job and look over your own machine, it all becomes obvious. Some tips: Work cleanly, you will be dealing with dryer dust and shredded gasket material. Use a vacuum and put down newspaper or a drop cloth. While you have it apart, clean the inside of the machine, and check the other moving parts (eg, rear bearing and drive belt). The glue for the rear drum seal is runny and dries fast so work reasonably quickly. I held the seal on with clothes pins and binder clips and glued about a foot of seal at a time. Everything else goes on easily. They dryer is like a new machine-good for another 30 years.

Other Parts Used:

-

Ed from SEBEKA, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum stopped spinning due to broken belt.

Step 1: Unplug the unit, then remove the lint screen and then remove the two screws beneath the lint screen cover. Step 2: At the rear of the dryer there is a small protective metal panel near the upper part of the dryer - remove this first; then at the front of the unit, insert a plastic pry tool between the front edge of the top and the front panel of the dryer and gently pry the top loose. Step 3: Lift the dryer top up and either remove it entirely or let it rest on the back edge and a wall for support. Step 4: On the inside of each side panel near the top front, locate the two screws holding the sides of the dryer to the front panel and remove them. Step 5: Carefully slide the front panel up so that the panel detaches from two metal clips holding the front panel onto the side panels. The drum will likely drop down slightly at this point since it is no longer being supported at the front. Step 6: On the front panel there is a wire that connects the front panel door switch. I left that intact because it was too difficult to remove without risk of breaking it and instead simply set the front panel to the side of the dryer - but if possible remove disconnect the wire and then set the front panel aside. Step 7: Remove the drum by pulling it out, inspect the back felt seal for wear and also the plastic split ring bearings at the front end. When you remove the drum belt the tensioner pulley underneath the drum will likely fall over, but this is to be expected because without the belt and drum providing tension, the piece only fits loosely in a slot at the bottom of the dryer. Step 8: Inspect the drum rollers, motor, and other parts for wear, then vacuum out the inevitable lint and dust inside the unit. Step 9: At this point I also decided to inspect and clean out the lint chute at the back of the unit, so I removed the protective back cover and removed the screws holding the lint chute in place. I then cleaned out the lint that builds up over time inside the chute and checked the two foam lint chute seals at the back of the unit - these needed replacing so I removed the old deteriorated foam and vacuumed off the back of the unit and then adhered the new seals to the back of the dryer. Step 10: Take the new multi-rib belt and drape it around the drum with the ribbed side against the drum - you will likely see a mark around the drum where the old belt was positioned, so use that as a guide. Step 11: Since one of the split ring bearings on my unit was worn, I replaced both at this time by simply pressing the plastic tabs out of the slots at the front of the drum, removed each half of the ring, and reinstalled the new parts - they only correctly fit one way so that the plastic edge lines up cleanly with the front edge of the drum. Step 12: With the felt drum seal toward the back replace the drum - I used a small box to support the drum upon while I reinstalled the drum - this will make it much easier to manipulate the belt around the tensioner and motor. At this point I reached underneath the drum and reinstalled the tensioner. by positioning it in the two small slots near at the bottom panel that are near the front of the dryer motor. Then take the belt and pull it through the tensioner and around the motor pulley at the front of the unit. You will likely have to push up slightly on the drum and tensioner to allow the belt to be pulled through the tensioner and around the motor pulley. Step 13: Rotate the drum slowly by hand at least one full revolution and check to see that the felt seal at the back is not pinched and that the belt does not fall off the pulley. Step 14: I removed the box supporting the bottom of the drum, then took the front panel and fit the front of the drum against it so that the split ring bearing matched up to the front panel. Step 15: The drum will still be somewhat loose and that allowed me to carefully lift the front panel up and then slide it down back onto the two metal clips that hold the front panel to the side panels. Step 16: Reinstall the two screws that also hold the front panel to the side panels. And if you also removed the wire connection to the dryer door, reattach that too. Step 17: If you removed the lint chute, reinstall it from the back while the lid is still off so that it is easier to slide it into position. Step 18: Reattach the top of the unit by seating it against the top of the frame (of course if you disconnected wires, reattach those too) and reinstalling the two screws underneath the lint screen cover. Step 19: Reattach the rear panel cover and small protective metal panel. Step 20: Reattach the flex-hose to the lint exhaust.

Other Parts Used:

-

Christopher from APOPKA, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Jack

March 21, 2022

Dryer noisy and seem loose in the front.

Is there a front seal that might be needed when replacing the basket front bearings?

For model number 110.75132412

Hello Jack, Thank you for your inquiry. There is also a seal and bearing, part# PS11773177, that goes behind the front of the cabinet. We hope this helps and if you need help placing an order, customer service is open 7 days a week. Please feel free to give us a call. We look forward to hearing from you!

1 person found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

- < Prev

- 1

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS334199

Manufacturer Part Number: 279441

Manufacturer Part Number: 279441

Brand

Model Number

Description