Product Description

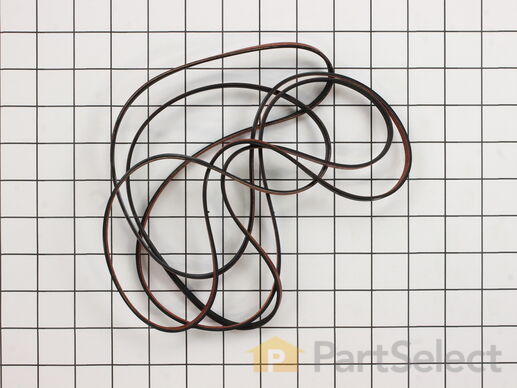

Multi Rib Belt - 92-1/4" Specifications

This dryer drum belt has four ridges, three grooves and is 1/4" wide.

How Buying OEM Parts Can Save You Time and Money

Troubleshooting

This part fixes the following symptoms:

Noisy | Drum Not Spinning | Heat stays on after drum has stopped | Too hot

This part works with the following products:

Dryer, Washer Dryer Combo.

This part works with the following products:

Kenmore, Whirlpool, KitchenAid, Norge.

Part# 341241 replaces these:

AP2946843, 529597, 341241, 14210003, 2008, 26000341241, 26000349533, 31001026, 31531589, 3389628, 3392665, 3394651, 3399844, 341241, 341241VP, 345473, 349533, 53-0186, 53-1080, 53-1086

...

Show more

, 53-1528, 53-1589, 53-2671, 53-2910, 660996, 660997, 661561, 693306, 694088, 694416, 694868, 695055, 697388, 8066065, 8206, 8210, 99906951, 99989673, 99989674, AP32, FSP341241, P46-037, P46-149, W10127457, W10131364

Show less

Customer Reviews

Filter By Rating:

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Manon R - 10 days ago

Verified Purchase

As expected

Good quality, fast delivery, as expected!

Angela N - December 19, 2023

Verified Purchase

Great part

The belt was in great condition. I installed by myself and saved a lot of money by trouble shooting the problem. Found this parts site online, as belt wasn't available locally for me. Delivery was swift and I will definitely purchase from this company again!!!Thank you!!

Gabriele G - December 14, 2023

Verified Purchase

The part was excellent and perfect.

The part came quickly and with our dryer not working is was great .. was easy to install following the directions and our machine runs amazing...Thank you

Kim R - December 4, 2023

Verified Purchase

Great part

My older Maytag dryer belt broke so model #s were not helpful. So I retrieved the belt and measured how long it was, and matched description for number of ribs in the belt. Placed order, it arrived quickly, installed —it fit. Dryer runs perfect now Thank you partselect!

Krista C - November 12, 2023

Verified Purchase

Easy repair

The part was in great condition and it came fast. It's all put together and working.

you tube help as well.

Jim R - September 30, 2023

Verified Purchase

Project to replace drum dryer bell

New belt arrived on time as scheduled . Compared overall length of new belt with old one. Watched Parts Select video on You Tube on how to replace belt .Project completed no problems

Mitch T - July 13, 2023

Verified Purchase

Easy

Worked perfect

DAVID R - June 18, 2023

Verified Purchase

Easy repair

Received dryer belt next day after ordering. It was exactly what I ordered. Made the repair that day and dryer was back in operation. Thank you!

Ken C - June 9, 2023

Verified Purchase

Perfect part!

our dryer is over 25 years old. This is the first repair it has needed. The part was very easy to find on the site; arrived quickly; and installed easily thanks to good design and a very helpful video located in the part page. 5 Stars!

Jeff M - May 18, 2023

Verified Purchase

Good price

Came quickly. Happy.

- < Prev

- 1

- 2

- 3

- Next >

Customer Repair Stories

Average Repair Rating: 3.4 / 5.0, 358 reviews.

What's this?

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Dryer tub belt broke

Removed the two screws that attatch the lent channel to the top of the dryer, then lifted the top of the dryer by pushing in on the two locking tabs located at the front , left and right , corners of the dryer top with a small flat head screw driver. The top of the dryer will fold back out of the way. At this point I removed the two 1/4 inch screws that are located on the inside of the dryer front left and right corners that hold the front panel/door to the two side panels. Now I was able to lift the front panel up and set it to the side. The bottom of the front panel that contains the dryer door that I just removed was held on the bottom by two clips that slide into slots on the front panel and did not require any removal to disconnect the bottom of the front panel, just pull up on the front panel. Since the tub was held in place by floating on a seal at the back of the dryer and a seal on the front panel , which I just removed the tub is now free floating except for the two alignment roller wheels at the bottom of the tub. It is easier if you lay the dryer on its back at this point with front of the tub pointing up. I pulled the tub out and cleaned the years of built up lent and removed all the pieces of the old , destroyed, belt. Note, the belt tentioner is located at the front of the motor which on the bottom right hand side. If your belt is broke like mine the tensioner may/will fall to the back of the dryer when you tilt it back, but do not worry. Once the dryer was cleaned up I put the tub back in place , still on its back and made sure the two alignment rollers were in place and rolled freely when the tub was turned by hand. Another note, my original belt tensioner did not have a rolling wheel that the belt rode on , but was a semi-circle smooth surface that the belt remained in constant friction with when the dyer was running, so I made sure the replacement tensioner I ordered with my new belt did have a rolling wheel that the belt would ride on, which I believe will reduce wear and extend the belt life. The new belt came with a diagram of the belt and tensioner routing which was helpful. Note: do not take the tensioner wheel off/apart when trying to route the belt. Follow the instructions routing diagram. The tensioner is held in palce by inserting the bottom back half into the slot in the bottom floor of the dryer making sure it is aligned with the belt pully on the shaft of the dryer motor. The dryer is still on its back side. Now, it was easier for me to route the belt around the center of the tub, following the marks from the original belt, and hold in in place in a few spots with masking tape and then route it thru the tensioner and onto the front pully of the motor. Make sure you have the grooves of the belt against the tub and the grooves are aligned with the pully on the motor. Now you can remove the masking tape that was holding the belt around the tub and spin the tub by hand watching the belt making sure it is not in a bind and is traveling around the motor pully , tensioner and tub freely. Make sure the tub is still sealed on the back side wall. As you turn the tub by hand you can adjust the belt by hand so that is following the original marks around the tub left by the orignal belt. Also double check the two alingment rollers and make sure they are spinning and on track. Now put the front panel with the door on by sliding it onto the two clips that are one the bottom at each side and put the two screws in that hold the front panel to the two side panels. Now stand the dryer back up and spin the tub by hand again making sure it has a good seal on the back side and on the front panel. Pull the top back down and put the two screws in that hold the lent channle to the top. I am not sure when the belt started failing on my dryer, but was amazed at how quiet it runs now. Guess I was use to the extra noise made by a dryer that was about to die. This was a cheap and easy repair and glad I did it myself.

Other Parts Used:

-

Ray from Denton, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1302 of 1408 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

intermittant heat

First I shut off the gas supply and disconnected the dryer vent and unpluged the unit so you can access the rear of the dryer. Then I removed the rear cover. This is where you will find your thermostats and fuses. Holding the new part next to the one to be replaced I transfer the wires one at a time so as not to get them mixed up, then unscrew the old part and install the new one. Insert a flat blade screwdriver under the top cover in the 2 front corners to unsnap it from it's clips, also at this time you need to remove the 2 screws that hold the upper part of the lint filter tube to the lid, then lift the lid to expose the drum ( I tilted the dryer back as far as the flex gas line would allow me to and rested the top lid against the wall without removing it, to many wires). Behind the front cover in the top right corner is the plug for the door switch,un-plug it and also there are 2 screws one in each corner. After that lift the front cover straight up and pull it away from the cabinet ( it has clips at the bottom to hold it in place). Reaching under the drum on the right side pull down on the belt tensioner and release the belt from the motor then you can remove the drum. Laying the drum down on it's front edge I removed the rear felt seal and took a piece of sand paper to rough up th old glue and clean off some of the felt that was still stuck to the drum. Following the directions from the seal package I put the glue around the edge of the drum and re-installed the new felt. This is a good time to clean out your dryer, while the glue sets up. A shop vac works the best, but be carefull not to suck up the money, it will help pay for the repair ( I found over a dollar in change ). At this time I also changed the coils on the gas valve, remove the 2 screws that hold the clamp and replace them one at a time. Re-install the drum with the belt on it, fold it and push it through the tensioner and put it on the motor pulley. rotate the drum to make sure that the felt is not kinked under itself, re-install the front cover bottom clips first, then the 2 screws and the plug for the door switch, pull down the lid and snap it in place, before installing the rear cover this is a good time to remove the rear cover to the lint chute and clean in there also ( it's easy to see why there are so many dryer fires). Re- install that cover and the rear cover and vent tube, turn your gas back on and check it for leaks ( even if you didn't disconnect it) plug your dryer back in and get busy catching up on the laundry that you haven't had a chance to do because your dryer broke, then smile and think about all the money you saved by doing this simple repair your self. Thanks Parts Select

Other Parts Used:

-

Paul from Monmouth, IL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

480 of 529 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wife told me Dryer would make a funny sound, then stop + had an a funny smell as well. The Electric motor that drove the unit was overheating and locking up, It was time to be replace.

The best part of my repair was I had everything back in service in 3 days. And one of these days was to consider just buying a new dryer. Had parts overnited and all parts fit and easy to replace.

1) Removed back - 6 screws

2) Removed dryer vent - 2 screws on top, 3 on bottom

3) Popped the top open

4) Removed Front of dryer cabinet - 2 screws

5) Removed Belt

6) Removed Drum

7) Cleaned up all lint

8) Pop off motor retainers front and back

Here is the tricky part for me.

9) Removed vent fan on back of motor.

I did not know that the back of the fan was square, and you could put an open ended wrench on it to hold it while you also have a vice grip on the front motor shaft. Then its a simple left to loosey operation. I first tryed to turn the fan blade to take it off, but proved to be to tight.

10) Repeat backwards to reassemble

While I had it apart I also replaced the Drum support rollers & Installed a new belt. Not that diffucult of a repair Good Luck, was certainly better than buying a new one at + $300.00 at Black Friday rates.

1) Removed back - 6 screws

2) Removed dryer vent - 2 screws on top, 3 on bottom

3) Popped the top open

4) Removed Front of dryer cabinet - 2 screws

5) Removed Belt

6) Removed Drum

7) Cleaned up all lint

8) Pop off motor retainers front and back

Here is the tricky part for me.

9) Removed vent fan on back of motor.

I did not know that the back of the fan was square, and you could put an open ended wrench on it to hold it while you also have a vice grip on the front motor shaft. Then its a simple left to loosey operation. I first tryed to turn the fan blade to take it off, but proved to be to tight.

10) Repeat backwards to reassemble

While I had it apart I also replaced the Drum support rollers & Installed a new belt. Not that diffucult of a repair Good Luck, was certainly better than buying a new one at + $300.00 at Black Friday rates.

Other Parts Used:

-

Mark from Fremont, NE

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

425 of 472 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Heat

Lift the top. Remove (2) screws holding the front of the dryer in place. Lift the front off the 2 retaining clips on the bottom of the dryer. The hardest part of the install was removing and replacing the igniter. A couple of helping hands from the girlfriend to hold the parts in place while I replaced the two screws was very helpfull. Installing the multi rib belt was also very easy with the help of a second pair of arms to reach under the drum to thread the belt onto the tensioner. The lint filter, of coarse was just a matter of throwing the old cracked one away and replacing w/ the new.

Other Parts Used:

-

Stan from Riverside, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

388 of 404 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky dryer

My wife had been complaing about excessive noise from our 25 year old dryer so after DISCONNECTING the dryer from the wall outlet I popped the top panel loose @ the front with a screw driver @ each front corner @ took a look. No cause was visible so I removed the rear cover & still nothing so I laid the dryer on it's back to remove the front cover. First the 2 wires to the door switch were disconnected then the 2 screws @ the top corners that hold the front panel to the side panels were removed. The front panel then slid up & lifted off exposing the front of the drum, belt & support pulleys. Upon inspection I found the bottom support pulley sleeve bearing to have worn out. Both pulleys were replaced because they only come as a pair now along with the tensioner pulley (idler pulley), the belt & the rear lip seal on the drum since it had a 4" section missing from the edge @ one point (all of these were the original components). Replacing the rear drum seal took the most time because the old adhesive had to be removed. I did this first so the glue could set while I installed the new pulleys & belt. By the time they were installed, the glue had set enough & I could continue the re-assembly.

We now have a 25 year old dryer that sounds like it's new & @ a fraction of the cost

We now have a 25 year old dryer that sounds like it's new & @ a fraction of the cost

Other Parts Used:

-

CHRISTOPHER from MOUNT AIRY, MD

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

155 of 167 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken tumbler belt

1. Removed the screws from the lint catcher

2. Removed the bolts from upper rear of dryer

3. Pried off the dryer top from the front (it rests on rear hinges)

4. Disconnected dryer door wiring

5. Removed bolt from inside upper front corners; removed front panel (be careful: the edges are sharp and the tumbler will fall when it loses support)

6. Removed broken belt and lint from interior parts; removed tensioner (which had fallen out of place). Note: The newer models have a tensioner pulley; my older model had a smooth semicircle that was confusing at first glance

7. Flipped dryer onto its back (for easier reinsertion of new belt and tumbler)

8. Placed new belt on tumbler; reinserted tumbler

9. Inserted new belt through tensioner, inserted tensioner "legs" into grooves on floor. Note: The belt will pull the tensioner upright when it's inserted properly (which isn't obvious at first)

10. Made sure belt and tumbler seal were properly installed

11. Replaced parts in reverse order

The process took over an hour because I couldn't figure out how to insert the belt through the tensioner. The trick is to insert the folded belt through the tensioner and onto the motor pulley. If I had to do it again, it would take about 30 minutes (including cleaning lint)

2. Removed the bolts from upper rear of dryer

3. Pried off the dryer top from the front (it rests on rear hinges)

4. Disconnected dryer door wiring

5. Removed bolt from inside upper front corners; removed front panel (be careful: the edges are sharp and the tumbler will fall when it loses support)

6. Removed broken belt and lint from interior parts; removed tensioner (which had fallen out of place). Note: The newer models have a tensioner pulley; my older model had a smooth semicircle that was confusing at first glance

7. Flipped dryer onto its back (for easier reinsertion of new belt and tumbler)

8. Placed new belt on tumbler; reinserted tumbler

9. Inserted new belt through tensioner, inserted tensioner "legs" into grooves on floor. Note: The belt will pull the tensioner upright when it's inserted properly (which isn't obvious at first)

10. Made sure belt and tumbler seal were properly installed

11. Replaced parts in reverse order

The process took over an hour because I couldn't figure out how to insert the belt through the tensioner. The trick is to insert the folded belt through the tensioner and onto the motor pulley. If I had to do it again, it would take about 30 minutes (including cleaning lint)

Other Parts Used:

-

Michael from San Antonio, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench set

130 of 149 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer was sqeaking loudly when running

I Looked on internet sites for this type of problem.

Most sites said the support rollers could cause this.

I found your site PartSelect and with help of your diagrams of the machine ordered the parts I thought were needed plus other parts that might cause the problem.

With machine torn down I replaced the rollers.

I had also ordered the main drive belt and idler assembly with the rollers and these also needed replacement. It is a good idea to order other suspect parts when doing this type of repair since you can return the parts not needed.

Your return policy is great.

Edward Brennan

Most sites said the support rollers could cause this.

I found your site PartSelect and with help of your diagrams of the machine ordered the parts I thought were needed plus other parts that might cause the problem.

With machine torn down I replaced the rollers.

I had also ordered the main drive belt and idler assembly with the rollers and these also needed replacement. It is a good idea to order other suspect parts when doing this type of repair since you can return the parts not needed.

Your return policy is great.

Edward Brennan

Other Parts Used:

-

Edward from Andover, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

124 of 146 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken belt - drum would not turn

Started out taking the back off, then found online that access is from the front and much easier to get to. Simply pop the hinges in the back of the top panel and then the front of the top is popped off. From there, it is easy to remove the old belt, clean the innards (found 31 cents) and replace the new belt. It was a little disconcerting to see the idler pulley laying loose inside, but the diagram showed exactly how to put it back in place, with the new belt keeping it in place.

Other Parts Used:

-

Gary from Oakland, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

81 of 95 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer made a loud noise and vibrated badly

First I made sure the unit was unplugged. I popped the top of the unit with a slotted screw driver, lifted the top up and rested it against the wall behind the dryer. I removed the two screws - one on each side in front on top of the dryer cabinet. Then I tipped back the front panel of the dryer slightly with the door of the dryer closed. I unclipped the door switch with a slotted screw driver and then lifted the entire front panel including the door off of the the two floor clips on bottom. I set the front panel aside. Next I lifted the large drum slightly to dislodge the rollers in back and slid the drum back slowly while sliding the thin belt back on the drum until the drum was out of the unit and the belt was detached and loose. Then I cleaned the unit thoroughly, vacuumed all lint and dirt and wiped down the outside of the large drum with mineral spirits to make sure it was totally clean and smooth. Then I removed the two rollers and the roller shafts at the back of the unit following the directions enclosed. My slip-ring pliers came in handy to remove the retaining rings on the roller shafts. I replaced the rollers and roller shafts and the supplied washers and spacers as per the instructions. I sprayed a little WD-40 on the surface of the rollers and it stopped all squeaking and vibration of the drum. Next I replaced the front drum pads and runners as per the instructions. I then slid the drum back in place taking care to slide the new belt back around the drum in the same position as the old belt. Now came the difficult part - laying on the floor and reaching under the drum I positioned the belt around the motor shaft and tension pulley. This must be done by "feel" and must be done correctly!! Follow the instructions on the positioning of the belt very carefully and make sure it is in the correct position on the drum, motor shaft, and tension pulley! Next, get up and rock the drum up and down slightly to make sure it has engaged the two rear rollers properly. Rotate the drum manually one or two turns to make sure the belt is in the correct position. Then replace the front door panel by dropping it onto the two clips at the base of the unit and taking care to replace the door switch in reverse order of taking it out. Then replace the two screws at the top front on each side of the unit to secure the front panel. Lower the top of the unit back in place, plug in the dryer, turn it on and enjoy the lack of noise you have created.

Other Parts Used:

-

Thomas from Oneonta, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

65 of 75 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start.

The first issue I had was diagnosing the problem, but after researching on the internet I was able to determine that the High Limit Switch caused the Thermal Fuse to blow. I found instructions on how to check the Thermal Fuse with an Ohm Meter, which was bad. This was a simple test. I removed the Thermal Fuse from the machine and tested it by using my Ohm Meter on the continuity setting. The instruction said that the fuse should always be closed and have continuity. Simply put, its like having a light switch in the on position. I put the leads from the Ohm Meter on the two connectors of the Thermal Fuse and found that there was no current passing through it, telling me that it was bad and needed replacing.

The bigger issue for me was what caused the Thermal Fuse to go bad in the first place, which was evident after I opened the dryer to check the part. The dryer was full of lint. Now understand that the lint that was inside the dryer was just a dusty coating, but I am one of those people that when he takes something apart and it is dirty I have to clean it before I put it back together, which payed off for me.

I removed the front panel to make it easier to clean the machine. This is when I noticed that the lint trap was almost completely blocked. Most people like me just before starting a load will clean the lint screen, but we never think that over time some of that lint gets by the screen and has to go somewhere. Well in this machine this happened and eventually clogged the tunnel leading out of the machine, which caused the machine to not be able to breath, which caused the heating element to overheat and blow the Thermal Fuse. I also used this time to inspect the rest of the machine, which again payed off.

During my inspection I found that the belt was beginning to fray, the drum seals were starting to tear and the pads under the drum glides had started to fall out, so I decided to order all the parts and refurbish the machine.

While I was waiting on the parts to arrive I disassembled the machine and cleaned everything and removed the old parts.

The first step I took was to clean out the lint tunnel on the front panel of the machine. To do this I first had to remove the front drum seal which is held on using a double sided tape. I then opened the door and removed the two screws that held the tunnel in place. I then removed the tunnel from the front panel and was able to remove all the lint that was clogged inside. This tunnel also has a foam seal, which is used to seal it against the front panel stopping the lint from escaping into the inside of the dryer compartment, which I also replaced. It was easy to install as it comes with a self adhesive backing. The next step was to reassemble these parts in the reverse order that I took them apart. This is where I ran into my first setback. Reinstalling the tunnel was not a problem but, when I went to install the felt drum seal I found that it did not come with a self adhesive backing and I had no way to secure it on the machine. So I had to go the next day and purchase some double sided tape which I used to attach the seal.

The next thing I did was to remove the drum from the machine. I did this by reaching inside the machine and releasing the belt off the tensioner. I then took hold of the front of the drum and lifted it slightly while pulling it towards me which allowed it to pop off the rollers which the back side of the drum rides on. I then removed the felt seal from the back side of the machine. This seal was a little more difficult to remove as the factory glues this seal in place. I cleaned this surface and reattached the felt seal using the double sided tape.

The next step was to replace the front drum glides. These glides are a two part component. The first part is a Teflon coated glide and the second part is a felt pad that goes underneath it. I removed the old parts, cleaned the surfaces and reinstalled the glides in the reverse order.

The bigger issue for me was what caused the Thermal Fuse to go bad in the first place, which was evident after I opened the dryer to check the part. The dryer was full of lint. Now understand that the lint that was inside the dryer was just a dusty coating, but I am one of those people that when he takes something apart and it is dirty I have to clean it before I put it back together, which payed off for me.

I removed the front panel to make it easier to clean the machine. This is when I noticed that the lint trap was almost completely blocked. Most people like me just before starting a load will clean the lint screen, but we never think that over time some of that lint gets by the screen and has to go somewhere. Well in this machine this happened and eventually clogged the tunnel leading out of the machine, which caused the machine to not be able to breath, which caused the heating element to overheat and blow the Thermal Fuse. I also used this time to inspect the rest of the machine, which again payed off.

During my inspection I found that the belt was beginning to fray, the drum seals were starting to tear and the pads under the drum glides had started to fall out, so I decided to order all the parts and refurbish the machine.

While I was waiting on the parts to arrive I disassembled the machine and cleaned everything and removed the old parts.

The first step I took was to clean out the lint tunnel on the front panel of the machine. To do this I first had to remove the front drum seal which is held on using a double sided tape. I then opened the door and removed the two screws that held the tunnel in place. I then removed the tunnel from the front panel and was able to remove all the lint that was clogged inside. This tunnel also has a foam seal, which is used to seal it against the front panel stopping the lint from escaping into the inside of the dryer compartment, which I also replaced. It was easy to install as it comes with a self adhesive backing. The next step was to reassemble these parts in the reverse order that I took them apart. This is where I ran into my first setback. Reinstalling the tunnel was not a problem but, when I went to install the felt drum seal I found that it did not come with a self adhesive backing and I had no way to secure it on the machine. So I had to go the next day and purchase some double sided tape which I used to attach the seal.

The next thing I did was to remove the drum from the machine. I did this by reaching inside the machine and releasing the belt off the tensioner. I then took hold of the front of the drum and lifted it slightly while pulling it towards me which allowed it to pop off the rollers which the back side of the drum rides on. I then removed the felt seal from the back side of the machine. This seal was a little more difficult to remove as the factory glues this seal in place. I cleaned this surface and reattached the felt seal using the double sided tape.

The next step was to replace the front drum glides. These glides are a two part component. The first part is a Teflon coated glide and the second part is a felt pad that goes underneath it. I removed the old parts, cleaned the surfaces and reinstalled the glides in the reverse order.

Other Parts Used:

-

Polly from Winder, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

64 of 1026 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Christine

July 20, 2017

When installing the belt how should the grooves be facing?

Hello Christine, great question! When installing the belt, you should have the groove side facing the drum. I hope this helps!

147 people found this helpful.

Was this helpful?

Thank you for voting!

Lawrence

July 20, 2017

My dryer is struggling to rotate during a drying cycle but the belt is new, where should I start?

Hi Lawrence, based on your symptoms it sounds like a bad motor that needs replacing. Please let us know if you have any further questions.

55 people found this helpful.

Was this helpful?

Thank you for voting!

Mona

July 20, 2017

Just replaced the belt not too long ago and they symptoms im experiencing include a loud squeaky sound and long drying times

Hello Mona, we recommend checking your exhaust duct in your home, as this is the most common cause for the long drying time. For the squeaking sound, you should check your drum rollers 349241T and your idler pulley WP691366. Best of luck with this repair!

44 people found this helpful.

Was this helpful?

Thank you for voting!

Bryan

August 29, 2017

Where can I find the belt for this model

For model number LER7620LG0

Hi Bryan,

Thank you for the question. The belt attaches to the drum, idler pulley, and motor pulley. You will need to remove the top and front panel to expose the drum and see where the belt is located.

Hope this helps!

24 people found this helpful.

Was this helpful?

Thank you for voting!

Paul

December 8, 2017

What's the part number for belt and drum support wheel

For model number LG7681XSW2

Hello, Thank you for contacting us. I have researched the model you have provided and have found the part you’re looking for is PartSelect Number: PS346995 for the Belt and PartSelect Number: PS347627 for the drum support rollers. Hope this helps!

21 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Arrt

October 15, 2017

How do you decide what platform belt to purchase for my model?

For model number cde6500w

Hi Arrt,

Thank you for your question. You would want to purchase the belt that is directly found underneath your model number. This would be the correct belt according to your model number. Good luck with your repair.

19 people found this helpful.

Was this helpful?

Thank you for voting!

Jamie

November 28, 2017

Do i need a belt for a 27" drum or 29"

For model number KGYS750JQ2

Hi Jamie,

Thank you for your question. According to your model information this is the correct belt for your appliance. Good luck with your repair.

18 people found this helpful.

Was this helpful?

Thank you for voting!

Karen

September 6, 2017

I can't find steve nash video for this fix

For model number RED4640YQ1

Hi Karen,

Thank you for your inquiry. We do not have an installation video for this part as of yet. However there are quite a few detailed installation instructions from other customer's down below that may help you with your installation. Good luck with your repair.

18 people found this helpful.

Was this helpful?

Thank you for voting!

Ray

December 17, 2017

I replaced the parts using the install kit. I noticed that my previous belt was broken. My issue now is that the drum is still not turning and the dryer is burning something, as there is now a smoke smell. Any suggestions?

For model number 11072832100

Hello Ray,

Thanks for your question. It may be worth replacing the drum glides or drum roller axles. If those parts are intact, it may be an issue with the motor itself.

I hope this helps.

5 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Shay

November 7, 2018

I have a Crosley dryer, and I need to replace the dryer drum belt. Where do I find the model number?

Hello Shay, Thank you for the question. Here is a link to help locate the mopdel number sticker on the appliance. Hope this helps!

https://www.partselect.com/Model-Number-Locator+5+repair.htm

3 people found this helpful.

Was this helpful?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS346995

Manufacturer Part Number: 341241

Manufacturer Part Number: 341241

Brand

Model Number

Description