41729 - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

washer wouldn't drain

First I turned off the breaker to the washer.

Then I removed the drain pump motor, saw that it was broken, and ordered a new one with expedited shipping. It was delivered about 36 hours later.

I should have used my wet/dry vac to suck out all of the water remaining in the drain lines. Because I didn't, nasty water dripped all over my laundry room. Lesson learned!

The part arrived at 2:20. I had to pick up my kids at school at 3pm. I wasn't sure I'd have time, but I tried anyway. I first removed the screws holding the entire pump assembly to the floor of the washer. Then I attempted to remove the clamps holding the three hoses onto the pump / motor assembly. I tried with regular pliers for about 10 minutes and finally realized I needed locking pliers. Mine are missing, but I have a stone mason doing a project at my house. I borrowed his and immediately had the clamps loosened. I slid them back onto the hoses, inserted the pump motor into each hose one by one, and reattached the clamps.

I ran a little water into the washer, checked to see that it didn't leak upon draining, then started a load and left to get my kids from school.

This was a very easy repair. The part was $75 plus about $20 for the expedited delivery. The Sears service call would have been $65 just to walk in the door PLUS whatever they would have charged me for the labor and the part. I am guessing I saved over $200.

The worst part was the gross water remaining in the drain lines. This would have been easily avoided if I'd just taken the time to get the shop vac. Learn from me and don't skip this step!!

Then I removed the drain pump motor, saw that it was broken, and ordered a new one with expedited shipping. It was delivered about 36 hours later.

I should have used my wet/dry vac to suck out all of the water remaining in the drain lines. Because I didn't, nasty water dripped all over my laundry room. Lesson learned!

The part arrived at 2:20. I had to pick up my kids at school at 3pm. I wasn't sure I'd have time, but I tried anyway. I first removed the screws holding the entire pump assembly to the floor of the washer. Then I attempted to remove the clamps holding the three hoses onto the pump / motor assembly. I tried with regular pliers for about 10 minutes and finally realized I needed locking pliers. Mine are missing, but I have a stone mason doing a project at my house. I borrowed his and immediately had the clamps loosened. I slid them back onto the hoses, inserted the pump motor into each hose one by one, and reattached the clamps.

I ran a little water into the washer, checked to see that it didn't leak upon draining, then started a load and left to get my kids from school.

This was a very easy repair. The part was $75 plus about $20 for the expedited delivery. The Sears service call would have been $65 just to walk in the door PLUS whatever they would have charged me for the labor and the part. I am guessing I saved over $200.

The worst part was the gross water remaining in the drain lines. This would have been easily avoided if I'd just taken the time to get the shop vac. Learn from me and don't skip this step!!

Parts Used:

-

Anita from Mission Hills, KS

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

24 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer making noise in the spin cycle:coin in pump

disconnected the power cord,removed two screws on lower front edge of machine, removed lower front cover. Got the wet vac ready to suck up the water in the rubber boots when I took the clamps off. Disconnect the pump wires, and two bolts that mounted the pump. wrestled off the boots, and cleaned out the junk in the bottom of the main boot, sucking up water as the boots came off. then reversed the process. Not bad at all. Makes you want to double check for coins so they don't destroy the pump impeller.

Parts Used:

-

Joseph from Somers, CT

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

23 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wouldn't go into high spin

this repair was easy, but it was repair #3.

#1: Fix-it guy said the front control board needed replaced. Ordered part from box store. Shoulda come here!

#2: Replaced motor control board. Harder to replace. Shoulda let the new front board run error code first. Again, used brand name supplier. Oops!

#3: Still not spinning. Error code "Door is open" but it's closed.

Remove door lock/switch assy, wires to the front board, and striker. 4 screws, 15 minutes. reached in through the top (did NOT unseat rubber around door).

Plugged wires into door lock. Inserted striker. Using multimeter on "Ohms" tested switch. No continuity=switch not closed.

New switch cost less, arrived faster. thank you Parts Select!

#1: Fix-it guy said the front control board needed replaced. Ordered part from box store. Shoulda come here!

#2: Replaced motor control board. Harder to replace. Shoulda let the new front board run error code first. Again, used brand name supplier. Oops!

#3: Still not spinning. Error code "Door is open" but it's closed.

Remove door lock/switch assy, wires to the front board, and striker. 4 screws, 15 minutes. reached in through the top (did NOT unseat rubber around door).

Plugged wires into door lock. Inserted striker. Using multimeter on "Ohms" tested switch. No continuity=switch not closed.

New switch cost less, arrived faster. thank you Parts Select!

Parts Used:

-

Kristofer from Crescent City, CA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

24 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Striker broke off

Replaced the old striker with the new one in about 5 minutes. Just needed a phillips screwdriver. Unbelievable how hard it was to find the part at local store...much easier to order from partselect. If I break it again, I will be all set. Part cost $7 vs repairman visit at a cost of at least $200 - - was worth the effort.

Parts Used:

-

Christine from Troy, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

24 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

locking mechanism spring broke

-

laura from willow creek, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

23 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Pump rotor broke off shaft.

There are two pumps in this system. I turned the washer on its side and took off bottom plate. There are several screws holding this on. I then took the entire pump assembly off. There are 3 screws holding each pump on the brown plastic body. Each pump has a positive and negative lead. I switched out the pump and reassembled. The hardest part is getting the 3 "shock absorbers in place with the rubber sleeves. I think the book suggest getting to the pump from the front side but I went through the bottom. Worked good. I did wonder however if the other pump was working. Do you need two pump working to get flow? By replacing one pump I went from no flow to good flow. Cost me $75.00

Parts Used:

-

Bill from COTTAGE GROVE, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

23 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water was filling continues even the machine was unplugged

I did repaired while looking at video at your site .thanks to your team ..

Parts Used:

-

Sanjay from HOLTSVILLE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisey sound getting louder during spin cycle

Please note that I went online first to get an idea of what was involved.

I removed the back panel using a cordless drill w/attachment for the screws. Then the top. The directions that I received online was very helpful, but I didn't remove the whole tub assembly. I don't recommend doing it my way, but it can be done without removing the front or the whole tub assembly. After the motor and the big pulley was removed, I removed the bottom "shocks". I then took out every one of the cap screws that hold the 2 halves together. When that was done the two halves were loose. I then supported the bottom and took out the two springs. The back half came out quite easily then. It is then necessary to use a mallet to remove the inner drum from the bearing and back half of the tub. I cleaned and inspected the "spider" which was fine except it had old soap in it. Then using a dremel tool with a plastic brush I cleaned/polished the shaft of the inner tub. The new rear shell fit perfectly. Supporting the bottom of the front half of the tub, I then placed the back half assembly (with the pulley replaced on the shaft) in proximity and started the cap screws. It is weird how the 2 halves don't want to stay in correct alignment, but it can be done. After I got most of the top screws in, I used a ratchet wrench to tighten them to almost where the 2 halves were touching. That helped with the alignment process. When all (Ibelieve there are around 17 screws) were started and the 2 halves were aligned, I then started at the top and tightened to a loose fit. The second time around I tightened to semi tight. At this time I could put the springs back on (greatly improves ability to reach the bottom screws). The third time around I put them all tight. Every thing went back on without a problem. I attached water and power to the unit and ran a cycle with the top off and checked for leaks. That's it.

I removed the back panel using a cordless drill w/attachment for the screws. Then the top. The directions that I received online was very helpful, but I didn't remove the whole tub assembly. I don't recommend doing it my way, but it can be done without removing the front or the whole tub assembly. After the motor and the big pulley was removed, I removed the bottom "shocks". I then took out every one of the cap screws that hold the 2 halves together. When that was done the two halves were loose. I then supported the bottom and took out the two springs. The back half came out quite easily then. It is then necessary to use a mallet to remove the inner drum from the bearing and back half of the tub. I cleaned and inspected the "spider" which was fine except it had old soap in it. Then using a dremel tool with a plastic brush I cleaned/polished the shaft of the inner tub. The new rear shell fit perfectly. Supporting the bottom of the front half of the tub, I then placed the back half assembly (with the pulley replaced on the shaft) in proximity and started the cap screws. It is weird how the 2 halves don't want to stay in correct alignment, but it can be done. After I got most of the top screws in, I used a ratchet wrench to tighten them to almost where the 2 halves were touching. That helped with the alignment process. When all (Ibelieve there are around 17 screws) were started and the 2 halves were aligned, I then started at the top and tightened to a loose fit. The second time around I tightened to semi tight. At this time I could put the springs back on (greatly improves ability to reach the bottom screws). The third time around I put them all tight. Every thing went back on without a problem. I attached water and power to the unit and ran a cycle with the top off and checked for leaks. That's it.

Parts Used:

-

Lester from Olympia, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

19 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

broken drum vane needed replacing

Front-loading Frigidaire washer made by Electrolux:

I removed the one phillips screw that secures the drum, but found the vane did not slide toward the front as I'd read it should. Nor was I able to squeeze the base to release it. I ended up using a rubber mallet and screwdriver to spring the snaps at the bottom of the vane. Once I had two of these on the same side out, I was able to slide the vane forward and remove it. Turns out there was a metal tab, part of the drum, bent into the vane so it couldn't slide for removal. I bent this tab down even with the drum surface, and the new vane slid in easily.

I removed the one phillips screw that secures the drum, but found the vane did not slide toward the front as I'd read it should. Nor was I able to squeeze the base to release it. I ended up using a rubber mallet and screwdriver to spring the snaps at the bottom of the vane. Once I had two of these on the same side out, I was able to slide the vane forward and remove it. Turns out there was a metal tab, part of the drum, bent into the vane so it couldn't slide for removal. I bent this tab down even with the drum surface, and the new vane slid in easily.

Parts Used:

-

Eugene from Westbrook, ME

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

"Le" Fail Code on digital display ... Washer would not agitate and made an odd noise.

I first thought there was a mechanical problem but after checking everything mechanical I discounted that idea ... I researched and found out from others with a similar problem that the Le code display was probably a sensor problem ... I ordered a replacement sensor ... With the new sensor available, I removed the access panel to the back of the machine (phillips head screw driver - 4 screws) ... Remove the exposed motor half (1 bolt - 17mm scocket) ... Loosen the motor stator that has the wired coils (10mm socket - 6 bolts) ... Hold motor unit to the side without disconnecting the wiring harness ... Disconnect the sensor wire connector and remove the old sensor ... Clip the new sensor in place (same position as the old one) and re-connect ... Reverse the assembly procedures ... This fixed the problem and the washing machine works like a new one ... The wife is HAPPY!

Parts Used:

-

Ronny from GASTONIA, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

18 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not drain OE error on screen

Wife wanted to spend $800 on a new washer." You don't know what your doing" she said. Parts Select not only showed me how to take it apart, but easy instructions to put back together and a "how bout them apples" to the wife!!!

Parts Used:

-

Karl from BERLIN, CT

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Strike broke off in door of machine

The washer door wouldn't shut. I saw the top piece of the plastic catch appeared to have a broken section. I looked online at the replacement part needed (this was the most difficult part of the process). I unscrewed the old piece and replaced it. No problems. I suspect that this is an engineered flaw with the machine to encourage more unit sales (it could be metal for instance). So fix it and feel clean!

Parts Used:

-

Egil from New York, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

18 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would not spin

Ran diagnostic and discovered that the panel did not recognize that the door was locked, thus no spin. I ordered both parts, although I didn't need the door strike/catch. I only needed the locking mechanism. I removed metal ring from around the rubber piece inside the door with needle nose pliers, and then I simply plugged in the new lock and screwed it in place. I put the ring back around the rubber piece, flipped the circuit back on and washed a load of clothes. Easy as pie! Teachers can do anything. Who needs a repair man? :)

Parts Used:

-

Terri from Glennville, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

19 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer was not draining

I shut the water off, unplugged the machine, and had to scoop the water out of the drum. When I opened the drain filter, about another half gallon of water came out. There are two screws that hold on each clip that secures the top. They are hard to see if you have a cramped laundry room and can't see behind the machine. The top slides back about 1-2 inches and lifts up, it can be tough to get it started. The rest of the machine came apart easily, just go slow and look for more screws if it does not come apart. I pried on the band that secures door near the spring to keep from distorting it. The website video was pretty good. The pump assembly has to come out the machine to replace it, the use a 10MM socket. Be careful not to over tighten when you reinstall. They are threading back into plastic. A long set of needle nose pliers works well for the clamps on the 3 hoses. Be sure to get all wiring back into it holders or vibration could cause grounding or shorting issues. I took some time to clear the small drain that is in the door seal. It was clogged with debris. The band was the most difficult thing to put back on. Start at the top. I used a flat screwdriver to help, but be careful not to poke a hole in the seal.

Parts Used:

-

Bryant from USK, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers, Socket set

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

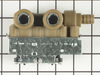

No Cold Water

Checked problem on-line and discovered it was the water inlet valve. Matched the part on part select. Com. Finding the part was very easy. Part select had a grid behind the picture to help determine the size and pictures from all sides. Removing the old part, matching it, and replacement took a total of 30 minutes. I now have clean clothes.

Parts Used:

-

Mark from Pittsburgh, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!