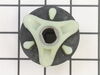

Hose Clamp

$11.68

In Stock

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

PartSelect Number

PS11743008

Manufacturer Part Number

WP596669

Manufactured by

Whirlpool

Product Description

Hose Clamp Specifications

This hose clamp extends from half an inch to an inch in diameter. It is made entirely of metal and is intended for use with Maytag brand washing machines.

How Buying OEM Parts Can Save You Time and Money

Part Videos

Replacing your Kenmore Washer Hose Clamp

Troubleshooting

This part fixes the following symptoms:

Leaking

This part works with the following products:

Washer, Dishwasher, Refrigerator, Washer Dryer Combo.

This part works with the following products:

Kenmore, Whirlpool, Maytag, KitchenAid.

Part# WP596669 replaces these:

AP6009835, 01-37-687, 113200024, 113200152, 113200392, 14206537, 16314, 2-11639, 2-14739, 2-1575, 2-16169, 2-2515, 2-985, 200985, 201575, 202515, 21002253, 211639, 214739, 216169

...

Show more

, 22002509, 22003018, 22003072, 22003073, 22003905, 2200954, 22294, 23001257, 23001506, 25-6049, 25-7796, 25-7867, 251830, 25988, 272794, 272796, 272844, 272845, 272846, 272847, 274337, 27643, 287859, 288446, 301958, 34001161, 34001207, 34001208, 34001224, 34941, 353366, 353367, 356436, 357821, 36801, 370450, 370451, 370452, 371501, 371503, 371505, 371506, 388000, 39282, 3955674, 4-0059, 4-0168, 4-0179, 4-10296, 4-10377, 4-179, 400059, 400168, 400179, 40054901, 410296, 410377, 4171914, 478572, 487728, 488157, 489257, 563972, 568692, 569097, 596110, 596471, 596508, 596669, 6-911856, 6-919982, 6-920322, 601105, 616148, 644261, 648470, 650369, 65036900, 650373, 660632, 660635, 67001408, 7-57247, 710082, 715453, 757247, 797369, 798017, 8055019, 8181537, 8181538, 8194172, 8318451, 8318490, 8318491, 8318492, 8318493, 8318494, 8318495, 8526324, 8526325, 8533946, 8541009, 866812, 866823, 9-0433, 9-0440, 9-11856, 900433, 900440, 911856, 9602-3, 965242, 965321, 9724996, 9724997, 98292, 983190, 98334, 98465, 98659, 99003634, 99003635, DC61-00219C, DC65-00008A, P113200024, P113200152, P113200392, R0601506, R0601540, R9800234, W10096851, W10096852, W10116736, W10117298, W10117299, W10156124, W10286344, W10286346, W10286356, W10286357, Y22003072, Y2200954, Y22294, Y757247

Show less

Customer Repair Stories

Average Repair Rating: 3.5 / 5.0, 17 reviews.

What's this?

- < Prev

- 1

- 2

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Washing Machine was leaking water

Loosened the hose clamp, removed the injector valve and injector nozzle assembly, replaced both and tightened with new hose clamp. Fixed the problem for less than $20!! Washing machine is 20 years old and this was the first problem--hopefully it is now good for another 20 years!

Other Parts Used:

-

jeff from lindenhurst, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

60 of 79 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cold water flow was slow

Removed old part; exchanged rubber plungers between the hot and cold. Symptoms still the same - so eliminated the need for new rubber plungers (even though they still needed to be replaced). The only item left were the magnetic switches opening and closing the flows. The syphon was replaced due to broken plastic mountings causing the syphon to hang into the drum. Repair was a snap and finding the parts on your site was very easy and parts were there within 2 days at standard shipping. Thank you.

Other Parts Used:

-

Garry from Palm Bay, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

22 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaked from top, left corner of machine.

Removed front of machine; then tilted back the top of machine, after removing the two screws in top front. Removed the old parts, trimmed the injector hose which was slightly longer than necessary, put new injector nozzle in ruber injector valve and inserted into the new sleeve, clamping the new hose to sleeve as well as clamping the remaining functioning hose to sleeve. The new sleeve mounting bracket was slightly different from the old one, but I was able to make it work with a small block of wood and two screws. The washing macine no longer leaks, the parts arrived timely, and the price was right. Thanks.

Other Parts Used:

-

Robert from Hudson, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

21 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer not rotating

Washer not rotating, removed the control head and back cover. Then removed body housing around tube to get to the bottom. had to replace coupling on motor then removed the agitator tower and replaced the Parts for the tower agitator. unit is 16 years young and still looks and runs new, put a total of 55 dollars into repair and it should be good for a long time. This is with a family of five. Washing 2 loads everyday.

Other Parts Used:

-

kaine from butler, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

21 of 174 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator Not Woking

Unplugged power cord then disconnected the water supply and drain hose. Removed 2 screws and took the front panel off. Laid washer on it's side and posistioned the transmission with the cover facing upward. Removed the hex head screws then used a razor knife and a putty knife to remove the silicone sealant. Found that the agitator shaft spring had broken and fallen into the housing jamming the gears that's used in agitation. Removed the oil and all broken pieces of the spring. Installed new shaft spring, replaced the oil then applied sealant to the cover and screwed the cover back down. Let the washer stay in the same posistion for about 18 hours to let sealant dry completely. Then I sat the washer back on it's feet and removed 2 screws that holds the top lid in place. This allowed me access to the tub cover where the injector t is located. Installed the injector t along with the injector tube seal. Connected the hose and hose clamp. Then I put the lid back down and secured with the screws. Connected the water supply and drain hose then the power and selected a wash time and observed the operation. Everything worked ok so I put the front cover back on. Note: I had used the injector t from this washer to fix another washer that an appliance dealer had given me to use for parts to repair the one just described above. That was the only thing that was wrong with it. It was used for about a year and a half and it developed a problem in the spin cycle. Appears to be a brake problem. I intend to repair it as well.

Other Parts Used:

-

Richard from Alexander City, AL

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water wouldn't stop

Unplugged washer then took back off control panel. Removed clamp and tube from pressure switch. Pushed in tabs with a screwdriver and lifted top. Removed clamp and broken tube. Put new tube in place and tighten clamp with nutdriver. Closed top and put other end of tube on pressure switch with clamp. Put back on control panel and plugged in. Clamps are to big for application but do work. So far so good!

Other Parts Used:

-

Steven from Westfield, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

17 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Weeping water control valve

Turned off water and power to the unit. Removed kick plate from under the dishwasher to access the water contol valve. Placed an absorbant rag under the water valve and water line. Disconnected solenoid on water control valve from electrical connection with my fingers. Used a standard adjustable wrench to disconnect the water line from the water control valve. Then used a 1/4" nut driver to loosen the two bolts that hold the water control valve on to the mounting bracket. Pulled the water control valve slightly forward to disconnect the water feed line to the dishwasher. Used a blunt end plier to pinch the clamp open and slowly wiggle the feed line off of the water control valve. Then removed 90 degree elbow off of the water control valve and used pipe dope and connected the elbow onto the new water control valve. Replaced water control valve in reverse order and utilized new hose clamp to reconnect feed line to new water control valve. Saved door seal for future use, when seal goes bad.

Other Parts Used:

-

Robert from Woodstock, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

17 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

improper or no hot water flow

After taking the entire washer apart one time, we learned that we could take the top and front of the machine off only to repair it. I found Part-select online and with the model number locating the part was easy. It arrived within 3 days and with instructions I could easily replace the old part with a few tools. I spent dollars instead of hundreds for a new machine.

Other Parts Used:

-

Cynthia from Manchester, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

16 of 23 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

leaking water under back left of washer

The first thing I did was look at the diagrams for my specific appliance on the parts select web site to locate fastners. I removed the front panel(2 screws 4" from floor on front panel), then removed the corner bolts of top panel(found under in front). Next I removed the 4 screws on the control panel (on top). I located the screw holdling the fill injector to the top Lid. Then I removed the clamp holding the unit to the regulator. Assembled the unit and placed it in position. First attaching the fill injector to top panel, then clamping the hose to regulator, then replacing 4 screws in control panel. Next the two corner screws in corners under the top panel. Replaced front panel and 2 screws. Then had a trail run and no water leaks any where.

Other Parts Used:

-

Gregory from Louisville, KY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking water rear left side

This happened once before and had I remembered how to get the front door off and lift the top it would have taken me less time. I actually spent more time assessing prior to ordering parts than in repairing once the parts came.

One odd thing - it only leaked when the hot water was entering (if the settings were on cold only no leak - no idea why that should be).

Anyway, this injector and the rubber housing it slides into get old and clogged or deteriorate. I ordered all the parts and replace them - but probably only needed to replace the plastic injector nozzel and the rubber sleeve it fits into.

All good now - no more leaks (until the next time!)

One odd thing - it only leaked when the hot water was entering (if the settings were on cold only no leak - no idea why that should be).

Anyway, this injector and the rubber housing it slides into get old and clogged or deteriorate. I ordered all the parts and replace them - but probably only needed to replace the plastic injector nozzel and the rubber sleeve it fits into.

All good now - no more leaks (until the next time!)

Other Parts Used:

-

Forrest from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Cathie

February 19, 2020

Dishwasher has runs water in floor soon as I hook it up. And with the door open looking inside on the left side there's a hole where the water runs into the washer, well this don't stop running when the door is open. I had noticed water was all over the floor after about 10 minutes of being turned on, that's when i had noticed that with the door open it did not shut water off as before .. help

For model number MDC4809AWB0

Hello Cathie, Thank you for the question. We suggest testing the Water Valve. The valve can be tested with a multi meter and should be reading between 500 - 1500 ohms of resistance. You can also test the Float Switch to see if it is closed. We hope this helps.

3 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Marcelo

April 8, 2022

New machine doesn’t turno water on and not working

For model number Wfw5620hw3

Hello Marcelo, Thank you for your inquiry. We have researched the model you have provided and we would recommend checking the following parts to fix your issue: the door latch, the single water inlet valve, the dual water inlet valve, and the water level pressure switch. You can test the parts with a multimeter. If you are unfamiliar with how a multimeter functions, we have videos available to assist you. We hope this helps and if you need help placing an order, customer service is open 7 days a week. Please feel free to give us a call. We look forward to hearing from you!

1 person found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

William

September 17, 2019

How does a clamp fix dishwasher filling with water after cycle is finished

For model number 66516462300

Hello William, thank you for your question. The Hose Clamp could be bent in such a way that it is preventing the water from travelling through the hose. I hope this helps!

Was this helpful?

Thank you for voting!

Frank

January 25, 2023

My front loading Amana door seal was replaced in November 2022, it still leaks.

For model number NFW7200 W

Hello Frank, thank you for contacting us. The issue is most probably related to a damaged wire diaphragm, part number PS11741554. It holds the door boot in place and helps in preventing leaks. If that is not the case, please check the hose clamp, part number PS11740613, and the door boot seal, part number PS11741579, for damage. Please reach out to customer service if you need help placing an order. Glad to be of help!

Was this helpful?

Thank you for voting!

Related Parts:

- < Prev

- 1

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS11743008

Manufacturer Part Number: WP596669

Manufacturer Part Number: WP596669

Brand

Model Number

Description