MVWB700VQ0 Maytag Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Washer entered spin cycle, but would not spin.

The washer would enter the spin cycle, but after starting to spin, would quit, and beep repeatedly. The fault code shown was DL. The manual cited DL as Door Lock malfunction. A check of the door lock switch suggested an internal problem. Sears offered the part at a far greater price, and shipping was several times more than PartSelect.com. PartSelect was chosen, and the part ordered on-line. Within two days the part arrived. Installation was simply a matter of lifting the top of the unit on which the door is supported. IT is done by inserting a narrow screwdriver into the separation, and pressing on the two metal springs holding the top in place. The old part was simple to remove by extracting two phillips head screws and removing the cable from the cable mounts underneath the top surface then threading the cable and plug back through the cable hole. Before that could be completed, the rear cover of the control panel was also removed, and after the plug of the defective switch was removed, the new cable was connected, and threaded back through in the reverse of the removal of the old switch, the phillips head screws, the control panel rear cover and returning the unit top to the resting position and snappin it into place. The Power ON check indicated that the problem fault code was cleared. The unit functions normally with the new switch. Hats off to PartSelect. The part was available in stock, and shipped promptly, and at substantially less cost than Sears.

Parts Used:

-

Paul from Rio Vista, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The agitator was making grinding noises

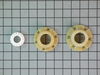

Removed the softener dispenser and cap that's under it. Used 7/17" socket with an 18" long extension to reach the bolt that holds agitator down. Pulled auger off, pulled lower agitator off. Removed the 6 philips head screws that hold basket hub in place. Removed hub and installed new one, replaced screws. Lightly greased spline and reinstalled lower agitator. The auger has the cam section in it. A trick to get the rollers in place is to secure them to the cam with rubber band. Have string tied to the band. Insert the cam and when almose all the way in, pull rubber band off and the rollers stay in place. Reinstalled the bolt, cap and softener dispenser.

Parts Used:

-

Mark from Erie, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

2 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken hinge pin.

-

Kevin from Tucson, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

machine gives uneven load alarm and f51 error code

Tilt the machine over to access the bottom I rested it on a dolly.remove the rotor with an allen wrench .then rmove the 4 bolts on the stator .then lift it off the main shaft and unlug the sensor wires . just reverse the process to install the new one (be sure to allign the arrows on the sensor and the stator when reistalling. I wish i could say this solved my problem .my machine runs untill the spin cycle then it starts shaking and gives the uneven load alarm again.

Parts Used:

-

Charles from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Water would not drain

I read the directions on this web site and was able to install the new drainage pump in about 30 minutes. I suprised myself. Thanks.

Parts Used:

-

Neil from Onalaska, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

drum made loud noise

put machine on side pushed old rods out to top installed new ones. runs like new. tried to ask mechanics or stores nobody would help with info, they all want to send mechanics with 80$ just to get here. it was easy to do. thanks

Parts Used:

-

axel from lighthouse point, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Drain Pump Leaks

Disconnect power and water. Remove the back panel of the washer. The drain pump is on the lower left corner (looking at the washer from the back). Access the electrical connection to the pump motor by lifting the lid where the wire enters the motor. You should be able to do this with your fingers and moderate pressure. Disconnect the electrical plug from the pump motor. Use pliers to remove the two hose clamps, one on the inlet and one on the outlet. Water may leak at this point so have some towels ready. Using a 5/16 wrench/nut driver, remove three hex head self threading bolds that connect the pump and motor to the underside of the tub. The replacement pump and motor go in in reverse order. Note that the replacement pump comes with a moisture shield. The shield installs on top of the new pump between the tub and the pump. It is difficult to see how the shield fits in place when fitting it to the replacement pump. The best way to see how the shield fits in place is to align it on the tub where the defective part was removed. Before testing the repaired washer, consider removing the inner tub and drain compartment cover (located at the bottom back of the inside of the washer). This takes some effort; however, it will save you from repeating this repair. Look for coins or other debris under the inner tub. For instructions on removing the inner tub and drain cover, go to youtube to watch or search for the model number and tub removal on your favorite search engine or youtube. Finally, use the spin and rinse cycle to test the repair. Look to see the pump drains the washer and ensure there are no leaks around any of the hose clamps. Good luck with your do it yourself home repair.

Parts Used:

-

Stuart from King George, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Old hinge broke, door did not open and close right.

I removed the screws from old hinge that had broke. The piece came right out with ease. I slid the new hinge in to the hole that it went in. No struggles with ease. Lined up the screw holes and put the screws back in. Finished! Works like a charm.

Parts Used:

-

tntsplace.com from MCALLEN, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Washer making noise down close to bottom of machine.

First unplug electrical, disconnect all hoses. If there is a large volume of water left in the machine you need to get it out.Pull machine out so you will have room to work. Lay machine front face down. Remove drive belt, inspection cover.Take the hose clamps back up the hose,remove hoses from pump. Remove the three screws that hold the pump in place.Replace pump, take steps back as you removed the pump to restore machine to operation.Total time 45 min. I am old and slow.

Parts Used:

-

Ronald from Demopolis, AL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

Hole in casing of drain pump due to loose nickle being pulled into pump - No screen in inlet to pump

Pulled back off of washer. Removed Spring clamps from inlet and outlet of pump housing. Removed hoses. Removed three screws holding pump in place. Disconnected electrical plug connector. Reassembled in reverse order. Note: new pump had no isolators and pump motor cover looked like a rat had chewed it up; however, motor, pump, and hoses appeared to be new. Put it on without the motor cover and it works. Epoxied the old pump housing to seal it up and now have a spare.

Parts Used:

-

CARROLL from HENDERSONVILLE, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Bearing's were shot and seal leaked water every where.

Replaced bearings, seal and new shaft. Washer never sounded this good, well I can't even tell it's running now. Very quiet. Just watch all the you tube vids on replacing seal and bearings and you shouldn't have any problems !

Parts Used:

-

Donald from Hedgesville, WV

-

Difficulty Level:Really Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Was this instruction helpful to you?

Thank you for voting!

vigoirously shaking causung UL code

-

Josh from Lodi, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

Was this instruction helpful to you?

Thank you for voting!

washer kept going out of balance

Removed cover and removed rods,replacing them one at a time.

Parts Used:

-

Bill from Gore, OK

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

washer would not drain water

need to get washer turned on side where you can work underneath the machine. This job is alot easy if you get where you can see good and have plenty of room to work. You have to unhoook the wire from the old pump and then take the two mounting screws off from there you unhook each hose by squeezing clamp together and sliding backwards away from pump. A pair of needle nose pliers can make this process easier if the clamps are turned in an hard to get to position. You mount the new pump the same way as taking off the damaged pump. Take a screwdriver to help you slide the clamps up onto the new pump makeing sure the sleeves are completely over the new pump fittings and the clamps are slid up evenly, so you want have any leaks. Then replaces wiring harness and mounting screws.

Parts Used:

-

Jacob from Glennville, GA

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!

replaced leaking pump

Easy repair. Went to You Tube and saw PartSelect video. The best instructions...should make a link from parts page to video of install. Also replaced Heat element on Dryer. Watched video first.

Parts Used:

-

richard from asheville, NC

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers

Was this instruction helpful to you?

Thank you for voting!