MDG6700AWM Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

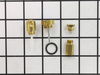

Convert dryer from natural gas to LP

The kit gave me parts for two different styles of gas valve and told me what to look for to identify one from the other. Very easy conversion.

Parts Used:

-

Douglas from New Lebanon, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

No heat

I feel like I have a new dryer now. I replace 3 of the 4 main components using parts select. Not only did they ship next day, but the tutorial videos with Steven were right on the money and self explanative.

Parts Used:

-

Steven from Oak Lawn, IL

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Bumpung or pounding sound.

I was working on my daughter’s Maytag dryer model MDE 9700 AYW. The dryer had been making a bumping sound for some time. It had the same symptoms a few years back, but it was still under warranty. The repairman had to replace a drum roller. He told her at the time he should replace all of them but he only had one with him. So when my daughter heard a similar sound she assumed it was a drum roller again so I ordered the roller without taking the dryer part. She has four boys that generate a lot of laundry, so she needs her dryer daily. I wasn’t sure how long it would take to get the part or do the repairs. The roller arrived very quickly, I think in a couple of days. The drum rollers on the dryer did not need to be replaced. What I found was bumping the side to the dryer because the sheet metal had popped inward. The drum has very little clearance on either side. The side probably could’ve used another crease or something to make it more rigid. My time wasn’t, wasted. I think it was will spent. I found that 3+ years of lint at piled up significantly on everything. The lint on the shroud for the heating coil had already turned brown and could have caused a fire. I would suggest to anyone who’s had a dryer for a while should open it up and vacuum out the lint buildup.

It only takes a Phillips screwdriver and very little time. It’s a very little investment for your peace of mind.

It only takes a Phillips screwdriver and very little time. It’s a very little investment for your peace of mind.

Parts Used:

-

Don from TAYLOR, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

the thermistor was open circuit

I change the Thermistor 3 bracket and worked well for 10 minutes and the thermistor is broken again

Parts Used:

-

Beatriz from Sharonville, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer stopped heating but everything else worked fine.

Unplugged the dryer and moved into clear working space. Removed back access panel and exhaust tube, they are connected. Noted the wire connection placement before removing all wires connected to heating element. Removed the one hidden screw securing the element in the very back, cant be seen remove by feel. Then with some force sliding forward removed the heating element. Dissembled heating element housing to revel burned out element, noted wire connections before unplugging and removing old element. Reassembled all parts as they were removed and starting using the dryer.

Parts Used:

-

Thomas from Forney, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

No heat

*Disconnect power cord before performing this task...(1) Remove the two screws holding top.(2) Remove four screws holding control module, tilt forward, pull up and unlatch. Place module on top, out of the way (still connected by wires). (3) Open dryer door, remove two screws holding lint trap assembly, close door. (4) Remove four screws on top of front cover, disconnect door light wire, tilt front cover forward, lift up from catch at bottom and remove. (5) Disconnect moisture sensor connection on bottom right for easier access to duct assembly. (6) Remove three screws holding duct assembly support bracket in place, raise duct assembly six inches to allow the bracket to be tilted toward rear and lifted out of the way. (7) Disconnect Red and Blue wires from front of duct assembly and pull assembly carefully from the rear of the unit and out the front paying attention to the wires still connected. (8) Remove wires connected to the thermostat and thermistor. (9) Remove screws holding in both units and replace with new components. (10) Reverse process and test. *note* if the unit appears to heat but clothing still wet, make sure moisture sensor was connected (I must have forgot and got to go back in to check, ooops). Regardless, this is an easy task. Could be intimidating at first but after the part has been accessed twice its no big deal and can be done over a lunch break.

Parts Used:

-

John from Kearney, MO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Dryer not staying hot

-

Lee from St. Louis, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!