90512 LG Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

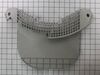

Lint Screen Housing broke causing damage to clothing

Could not do repair since the parts that I ordered were different from the picture on this site. I have emailed them to which they replied with one email asking for some info. I sent that to them and have not heard anything back in the last 3 weeks. I have even sent reminder emails and still nothing. I can't use my dryer due to damaging clothing and can't replace parts due to being the wrong part. Partselect is not very good at getting answers for their customers. Expert repair help is something i don't think they have. Getting some answers would go a long way but i feel like i have been left in the dark.

Parts Used:

-

Steven from Kenduskeag, ME

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

None

When manufacturer confirmed the part would fit without an adapter, it was the easiest DIY task ever undertaken.

Parts Used:

-

Ernest J from Columbia, SC

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

4 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

igniter would not light

Initially replaced igniter. Didn't think it was bad though. Read other suggestions on another website. None were the correct diagnosis for my situation. And when I figured it out they did not offer correct part. The dryer thermistor temp sensor (probe sensor) is what I replaced. Found it on Parts Select. I did replace other parts also. But that's the one that ultimately was the issue.

Was not hard at all if one is even a little handy.

Was not hard at all if one is even a little handy.

Parts Used:

-

Dave from SAINT JOHN, IN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The lint screen had a broken edge

The lint screen that this company sent was 3x too large. I called to return/exchange it. No one available - go to customer service.

I went to customer service and entered my email address and the order number (while I was looking at the original order1). The email and order number could not be found.

I am still waiting to hear from someone from the company to get a RMA and return label! Will NEVER use this company again.

Vivien Joebchen

I went to customer service and entered my email address and the order number (while I was looking at the original order1). The email and order number could not be found.

I am still waiting to hear from someone from the company to get a RMA and return label! Will NEVER use this company again.

Vivien Joebchen

Parts Used:

-

Vivien from CARLSBAD, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:Less than 15 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I would turn on the dryer it would run for about 10-20 seconds and then shutoff, and could smell something burning

-

Kevin from MASHPEE, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer door latch broken

-

Paul from OVERLAND PARK, KS

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Not heat

Followed the instruction on video.was great after three parts now is OK .we have heat.still cheaper than having it service.

Parts Used:

-

Sal from MORENO VALLEY, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Igniter burned out

Completely had to dismantle the dryer to get to the igniter.

The screw holding the igniter is a SOB to get at for extraction, and even worse putting back.,

The screw holding the igniter is a SOB to get at for extraction, and even worse putting back.,

Parts Used:

-

EDWARD from KNG OF PRUSSA, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer work but wouldn’t shut off when finished cycle, had to shutoff from breaker

With a thin flat screwdriver I was able to pry out the old door switch, I replaced it with the new door switch, pushed back in dryer and so far is working since I installed a month ago.

Parts Used:

-

joaquin from MIAMI BEACH, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

3 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat

I replaced the thermistor, then the gas ignitor which were easy to get to once the drum was out. The gas is still not igniting so not sure where to go from here. Putting the drum belt back on took some muscle. But then I'm 71.

Parts Used:

-

Barbara from CUDAHY, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

HST code given by dryer

Called LG on the phone and they gave the button presses for diagnostics, which then gave the HST code, saying the Humidity sensor was bad.

The part was described as the Humidity sensor module. Actually it's just the wire leads for the sensor which must be electronic and only accessible by disassembling the dryer. There were descriptions about cleaning the wires, perhaps because some people use dryer sheets which cause a buildup on the wires and prevent them from doing their job. I use wool balls and have no buildup on my wires and replacing them did not fix the sensor, because the module accessible inside the dryer is not the moisture sensor, but only the wire leads.

The part was described as the Humidity sensor module. Actually it's just the wire leads for the sensor which must be electronic and only accessible by disassembling the dryer. There were descriptions about cleaning the wires, perhaps because some people use dryer sheets which cause a buildup on the wires and prevent them from doing their job. I use wool balls and have no buildup on my wires and replacing them did not fix the sensor, because the module accessible inside the dryer is not the moisture sensor, but only the wire leads.

Parts Used:

-

marty from NEOSHO, MO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cracked lint filter

-

Richard from MADISON, AL

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

2 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Locker assembly broke

Just unscrewed the original lock and screwed the new one on it was very easy

Parts Used:

-

temeaco from TULSA, OK

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

LP to Natural Gas

The installation of the gas orifice was actually simple. Unscrew the old orifice and screw in the correct orifice. Tricky part of the process was accessing the area of the gas valve.

Parts Used:

-

Joani from BONNER SPGS, KS

-

Difficulty Level:Very Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

CHANGED OUT MOTOR

FIRST REMOVED THE LID ON TOP OF DRYER.THEN THE CONTROL PANEL AND THE STEAM TRAY. HAVE TO UNCLIP TWO HARNEST CONNECTORS. REMOVED THE FACE PLATE THAT HOLDS THE DRYER WALLS TOGETHER ALSO REMOVE TO SENSOR HARNESS CLIPS. .REMOVED THE BELT FROM MOTOR. TOOK DRUM OUT . UNCLIPPED MOTOR COLLAR SNAP CLIPS DISCONNECT THE MOTOR HARNESS. INSTALL NE MOTOR AND CONNECT HARNESS INSTALL CLIP . REINSTALL DRUM AND PUT BELT ON. CONNECT HANESSES AND INSTALL FACE PLATE. INSTALL CONTROL PANEL AND THE TOP LID.

Parts Used:

-

Omar from SILVER CITY, NM

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!