41799175100 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

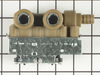

water leaked into machine when turned off

Removed top,removed hose from inlet valve to washer,removed hot and cold inlet hoses and with phillips screwdriver removed water inlet valve assy and replaced. Reassembled and tested.

My order arrived 2 days after i ordered same. Excellent service from partselect, Thank You....

My order arrived 2 days after i ordered same. Excellent service from partselect, Thank You....

Parts Used:

-

Henry from Frenchtown, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

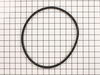

belt broke

i left my washer on its back till my belt came in and when it did all i had to do is slip the front off and go at it. it was really fast. then i put the front back on screwed in two screws and hooked up hoses and started washing everything went smooth till i was about to wash wash-n-wear and was like where is my other houseshoe and i remember my dog was bugging me while fixing my washer and dropped my house shoe and i already closed up front soi had to unhook everything and get that out, did not want it to catch on that belt i just bought and fixed lol thanks kristal cumpton

Parts Used:

-

kristal from caruthersville, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

clothes not drying in one cycle

remove top cover, remove front of dryer, unscrew two #2 screws from gas valve coil hol down bracket. replace coils. reassemble dryer.. works great.. had already replaced the thermostate and flame sensor.. didn't change anything.. the coil set did the trick..

Parts Used:

-

Aaron from Kerhonkson, NY

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Inlet valve leaked water from supply line(s) back into washer.

Pulled washer electrical plug from receptacle.

Unscrewed hot and cold water inlet hose connectors.

Removed screws retaining backplate.

Removed back plate.

Removed two screws connecting valve assembly to frame.

Pulled two spade electrical wire connectors from valve assembly.

Opened hose clip securing hose on outlet side of valve assembly, using pliers.

Pulled hose from valve assembly.

Valve assembly now free.

Reversed above with replacement valve assembly.

Unscrewed hot and cold water inlet hose connectors.

Removed screws retaining backplate.

Removed back plate.

Removed two screws connecting valve assembly to frame.

Pulled two spade electrical wire connectors from valve assembly.

Opened hose clip securing hose on outlet side of valve assembly, using pliers.

Pulled hose from valve assembly.

Valve assembly now free.

Reversed above with replacement valve assembly.

Parts Used:

-

John from Powhatan, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

female part of door clasp broke

-

Tammy from St. Peters, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wasn't heating

Determined that the coil on the gas valve wasn't pulling in to ignite. Using an ohmmeter, I determined the coil was open. The coil was removed by pulling off the wire connecter and removing the two phillips screws holding the bracket over the two coils. The coil then slides out. I slid the new coil into place, replaced the bracket and two screws and reconnected the wire connector. It worked immediately. The actual repair only took 15 minutes. The bulk of the time was spent tracking down which part had failed.

Parts Used:

-

Jack from Huntingdon, PA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Belt not tight

Tensioner (pulley spring) replacement.

The whole tub and motor are suspended by springs so I just got a flat bar and using the edge of the bottom of the washer as a fulcrum, lifted the whole thing enough to be able to shove a 2x4 under there at the base of the dome. It was still tight getting the lock washer off the bottom of the spring axel, but it popped off by pushing the ends with two screwdrivers.

The whole tub and motor are suspended by springs so I just got a flat bar and using the edge of the bottom of the washer as a fulcrum, lifted the whole thing enough to be able to shove a 2x4 under there at the base of the dome. It was still tight getting the lock washer off the bottom of the spring axel, but it popped off by pushing the ends with two screwdrivers.

Parts Used:

-

Richard from Rahway, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

5 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub cover seal leaks water.

Lifted lid/top of washer pulling straight up and removed front panel (2 screws at bottom). Removed old tub cover by prying tabs off the tub clips. Aligned new cover and seal over tub and pressed down to engage tabs with tub clips. Easy repair. Re-installed front panel and 2 screws, closed washer top by pressing down to engage the spring clips. I used anti-seize grease on the front panel screws and I used a small amount of petroleum jelly on the top/lid spring clips to make future removal easier(just in case.)

Parts Used:

-

Joe from Horseheads, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Belt

Very easy to install. Unscrew 2 screws and I was done in minutes. Thanks for the fast part delivery!

Parts Used:

-

Stephen from Honesdale, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer tub stopped spinning and was real noisy

I read the last three peoples experiences when I ordered the part on your on line page. I had already made all the wrong mistakes taking the machine apart, and couldn't beleive how simplified it was on your web site. I had called a local repair shop only to be advised the part would take 4 days shipping and the price of it plus shipping was twice what I paid you. Your part arrived the day after I ordered it on line, Thanks again for being there!!!!!

Parts Used:

-

Raymond from Brewster, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Not enough heat

Checked PartSelect online for people with a. similar problem. Found most common problem was the coils.

I opened the top, removed the two screws holding the front panel, unclipped the wiring harness from the machine to the door and removed/cut the plastic wire tie and front came off easily. I put the front piece to the side after changing the light bulb. I cleaned out a large amount of lint and found the coils on the left hand side without trouble. Carefully disconnected the wiring clips, unscrewed the holding screw and removed the old coils. Installed the new colis, 1 has three prongs and the other has 2 so you ca'nt mix them up. Replaced the hold screw, re-connected the witing harness, installed a new wire tie, and re-stalled the two holding screws. Closed the cover and turned it on.

At first it did not heat up which was dissappointing; but then I left it alone and 15 minutes later it worked like new! And heated up just fine ever since.

Total cost about $35.00 with shipping. I took a chance that I would not need the sensor or the ignitor based on the comments of others and I just bought the coils. If I had to do it over I would have bought all three and saved on the shipping.

I opened the top, removed the two screws holding the front panel, unclipped the wiring harness from the machine to the door and removed/cut the plastic wire tie and front came off easily. I put the front piece to the side after changing the light bulb. I cleaned out a large amount of lint and found the coils on the left hand side without trouble. Carefully disconnected the wiring clips, unscrewed the holding screw and removed the old coils. Installed the new colis, 1 has three prongs and the other has 2 so you ca'nt mix them up. Replaced the hold screw, re-connected the witing harness, installed a new wire tie, and re-stalled the two holding screws. Closed the cover and turned it on.

At first it did not heat up which was dissappointing; but then I left it alone and 15 minutes later it worked like new! And heated up just fine ever since.

Total cost about $35.00 with shipping. I took a chance that I would not need the sensor or the ignitor based on the comments of others and I just bought the coils. If I had to do it over I would have bought all three and saved on the shipping.

Parts Used:

-

John from Bergenfield, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy operation - "Chugged" during operation.

With prep work mentioned below and a good flashlight it takes about 15 to 30 minutes if you're a good handy-man. If you're not, get a neighbor or friend who is. This repair isn't rocket science, but does take a some mechanical aptitude. This unit is a washer/dryer combo unit. Unplug power cord and remove water supply hoses, the drain hose and dryer vent if required to obtain easy access to front panel. There is water in all the lines, so have some towels and a small gallon bucket to help drain the lines if disconnected. Remove two screws on bottom of front panel. Be sure there is about 2 inches from washer/dryer to floor in front to allow front panel to drop directly down, then pull panel out lightly. Wood spacers or similar are recommended under front feet to prop-up front of washer. (There are two tabs on each side of the front panel. The panel must be pulled straight down to clear tabs). Another option is tilt back the washer/dryer about 60 to 75 degrees unit to make the front panel more accessible if all is disconnected in back and you have the room to do so. Once the front panel srews are removed, you may have to place an object (thin pry bar or screw driver) between the top of the washer unit and the front panel for release (be careful not to dent or scratch the top metal or front panel. Remove front panel and set aside. Locate belt near bottom and tensioner pulley (it moves back and forth laterally), push in tensioner pulley to relieve pressure on belt and remove belt from small pully wheel at motor, then the large drum pulley wheel. Place new belt on large pulley first, then small pulley. Push in tensioner pulley and move middle of belt to the inside of the tension pulley to take up the slack. This process is somewhat hard. It takes good hand strength. Be sure the belt is aligned in pulley grooves. Place washer/dryer back in level position, re-attach water supply hoses, drain hose, dryer vent line and power cord, if removed for repair. Check for leaks in water supply lines and be certain the drain hose is well attached to the drain pipe. (This is a good time to clean or replace the dryer vent line to prevent possible lint fires.) Plug in washer/dryer unit and test as if washing a small load. Re-install front panel after successful test in run operation. The part came quickly and fit perfectly.

Parts Used:

-

Peter from Lynnwood, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squeek while the dryer is running.

1. After checking the Parts Select website for some useful information I unplugged the dryer.

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

Parts Used:

-

Miles from LaPorte, IN

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky drum until drum would not turn.

Watched on-line video, then applied those steps.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

Parts Used:

-

Doug from ODESSA, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The drier was "screeching"

First of all, the folks at Part Select have been terrific. I balled up my address and they were great in correcting my error and getting the parts promptly to me. They provide directions with the parts. And You Tube, is a wealth of information too. The process is to remove the drum and replace the nylon busihing that supports the drum at the back of the machine. Getting it out was no sweat. Getting the drum back in was a bit more challenging single handed. If I was going to make any suggestion it would be this is a good project for two sets of hands with the second set needed for about ten minutes. The You Tube video I watched said putting the front cover with the drum attached to the back of the unit would be the challenge and they were right. Otherwise, super easy and the results are it's back to "new" condition. Thanks again to Part Select!

Parts Used:

-

Michel from CHICAGO, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!