11088752796 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Motor runs, but tub does not spin or agitate

Woulkd have taken alot less time had I not taken off the control board, back...etc. Laying the unit on its back is perfect. Took it out into the garage when I could have done it in the laundry rooom with very little water loss.

1. Removed all hoses connected to top of motor. This was not very easy since the spring clamps had been in the same place for 20+ years. Also removed all wire harness connected to and from the motor.

2. Removed metal clamps from top of motor unit, and removed the plastic "valve".

3. Removed screws holding in clamps on each side of the motor used to hold motor on motor plate. Removed motor. Trick is to make sure that the back clamp stays in place...makes it a little easier when you go to re install.

4. Cleaned out around agitator shaft, and fitted one side of the coupling and the neoprene type joiner on to the agitator shaft.

5. Fitted other side of coupling on to motor...This is where it got a little tough......and then placed motor unit on the motor plate, making sure to line up teeth to neoprene joiner.

6. Replaced clamps on each side of the motor and screwed in nuts holding them in place.

7. Replaced plastic "valve" and the clamps that hold it in placed...back one is a little tough.

8. Reattached hoses to "valve" and hooked all wire harness back into place.

9.Tested perfect...little burning smell on first spin....but works great now!!

1. Removed all hoses connected to top of motor. This was not very easy since the spring clamps had been in the same place for 20+ years. Also removed all wire harness connected to and from the motor.

2. Removed metal clamps from top of motor unit, and removed the plastic "valve".

3. Removed screws holding in clamps on each side of the motor used to hold motor on motor plate. Removed motor. Trick is to make sure that the back clamp stays in place...makes it a little easier when you go to re install.

4. Cleaned out around agitator shaft, and fitted one side of the coupling and the neoprene type joiner on to the agitator shaft.

5. Fitted other side of coupling on to motor...This is where it got a little tough......and then placed motor unit on the motor plate, making sure to line up teeth to neoprene joiner.

6. Replaced clamps on each side of the motor and screwed in nuts holding them in place.

7. Replaced plastic "valve" and the clamps that hold it in placed...back one is a little tough.

8. Reattached hoses to "valve" and hooked all wire harness back into place.

9.Tested perfect...little burning smell on first spin....but works great now!!

Parts Used:

-

Danny from Woodstock, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washer pumps but does not spin

I did a Google search for the model number and found this site, PartSelect.com. Based on the diagrams on the site and what I could see underneath the washer, it was clear that the motor coupling was now gone and the shattered pieces of it were all over the floor. So I ordered a new coupling and waited for it to arrive, it was shipped in just a few days. Once I had the new coupling all I had to do was remove a couple of brackets holding the pump onto the motor, and the motor onto the gearbox; unplug the electrical terminals and lift the motor out. There are two halves to the coupling, one sits on the shaft of the gearbox and the other on the shaft of the motor. Both of these are seated into a rubber boot that is also a part of the coupling. Once the motor is sitting on the gearbox with all the coupling parts seated in place, just plug everything back in and replace the brackets. You will need a 1/4 socket to remove/replace the motor brackets. Also, it should be noted that you will want to unhook everything that is hooked to the wall (hoses, power cord) but it assumed you've already done this if you have access the the underneath of the washer.

Parts Used:

-

C. Scott from Fremont, NE

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

slow spin

-

eugene from abbott, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not spin to extract vwater

will not go over step by step here as there are already a multitude of stories on site with exact situation as mine who have already done so.. What I will say is that PartSelect is easily the absolutely best site on the net for a complete problem diagnosis to finished repair experience. Just input your model # and describe the problem and you get instant diagnosis probabilities along with access to a long list of customer Q & A and reviews, along with step by step videos on diagnosing, dis- assembling, and re-assembling along with links to all parts needed and also some secondary tips along the way. The prices are fabulous (example: I got a clutch assembly kit with several parts and 2 additional parts as a just in case for $55 shpg incl, while my local appliance parts place wanted $59 plus tax for just the main part in my assembly kit with a no return policy and no part guarantee, plus it was only 1 day more to have PartSelect pkg arrive than I would have gotten part from local store). This site is FABULOUS !!!

Parts Used:

-

Richard from WEEKI WACHEE, FL

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would fill with water but not start

Moved top control panel and pulled cabnet back changing switch,then reassembled,very easy,don’t forget to un plug

Parts Used:

-

LeRoy from OLYPHANT, PA

-

Difficulty Level:Very Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The air heater would not heat air to dry on the heat cycle

I misdiagnosed the problem as heater element because I did not have my voltage meter with me. The problem was the heat thermostat that senses temperature in the drum and burns out if it's too high. There are two other safety cut off thermostats that when triggered will reset themselves when the temp cools. All three should be tested before looking for something else, like the cycle selector switch; that one is not only more complex but very difficult to access. One is on the heater element itself, the other senses the temperature of air flowing out of the heater element. I believe this array of thermostats is similar on every drier. Each one should be tested with an electrical multifunction tester before guessing what's wrong. The drum thermostat, a $13 part, was the easiest to replace, once I got the back of the drier completely open, a not too difficult task. And, as I found out talking to a repairman, is the thermostat that most commonly fails. I will add that Partselect was most accommodating in providing advice and in authorizing me to return the heater element and refunding the overnight shipping fee. And their web site is terrific--the only drawback being you have to read it over thoroughly before concluding you are an "expert". I would work with them before any other vendors. Good luck!

Parts Used:

-

Roger from WEVERTOWN, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

start switch replace

i could not perform the repair because despite using the proper id numbers, i received the wrong parts from kenmore three times in a row. now i am trying to return the wrong parts which cost me 120.00 for the start switch, and the knob for the switch, so far. the switch was 40.00 the simple plastic button was (wrong) 40.00, and the wrong unidentifiable part, suposedly correct one, which also was 40.00. this, with the original 40.00 wrong switch amounted to the 120.00 that i am still trying to have returned. otherwise, the fix should be quick and simple, o yeah, its been three months.. you tell me if i am satisfied....

Parts Used:

-

john from GERBER, CA

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not spin clothes

Followed the video instructions. Had no problems. The video was accurate.

Parts Used:

-

Joseph from KEARNY, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Spin cycle worked very poorly

1. Removed back panel.

2. Removed Entire control paned, control and switch units disconnecting wiring assembly from motor.

3 Tilted front and side panel assembly away from frame, tub assembly and motor transmission assembly.

4.Removed cap from top of agitator, removed bolt holding agitator. Removed agitator, this part was tricky since some corrosion on shaft made agitator very difficult to pull off.

4. From bottom of unit disconnected motor/transmission unit from wash tub.

5. Located clutch assembly and removed lock washers. Removed clutch and replaced with new one.

------------------------------------------------------------

Steps 1 thru 3 were unnecessary.

All that needed to be done was to removed the agitator assembly. then turn unit on it's side or back and removed motor and transmission from the bottom.

2. Removed Entire control paned, control and switch units disconnecting wiring assembly from motor.

3 Tilted front and side panel assembly away from frame, tub assembly and motor transmission assembly.

4.Removed cap from top of agitator, removed bolt holding agitator. Removed agitator, this part was tricky since some corrosion on shaft made agitator very difficult to pull off.

4. From bottom of unit disconnected motor/transmission unit from wash tub.

5. Located clutch assembly and removed lock washers. Removed clutch and replaced with new one.

------------------------------------------------------------

Steps 1 thru 3 were unnecessary.

All that needed to be done was to removed the agitator assembly. then turn unit on it's side or back and removed motor and transmission from the bottom.

Parts Used:

-

Joseph from North Charleston, SC

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Socket set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer tub did,nt spin

leaned washer back on wall at or more than 45degree undid two screws off of motor. pulled old part off put new on reinstalled motor Done

Parts Used:

-

Patrick from Floyds Knobs, IN

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washing machine motor would run but the part that run the transmission was broke

We had to take the motor out and remove the coupling, when putting it back together we had some problems because the washer was on its side and the lid was open. After putting the motor and coupling back together we tried to turn it on, unknowing to us the lid was open so nothing would happen, finally we realized the lid was open. The actual repair was not complicated, just human error made it seem than way

Parts Used:

-

LYDIA from HIGH SHOALS, NC

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

grinding noise and would not agitate

I loosened two screws which held the knob panel in place. I undid the two clips holding the cabinet and removed it. The pump has two clips holding it on, I removed those and the pump came free. Taking advice from these forums, I did not remove the hoses attached. I disconnected the wiring harnesses from the motor. The motor has 2 clips also, these being held on with screws. I removed the screws and the clips. THE MOTOR IS HEAVY.

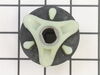

You will see the coupling on the "spindle" of the motor. In my case, both plastic pieces were cracked in 2 places. I removed the old coupling and cleaned the "spindles" and lightly regreased.

The replacement pieces I ordered were the "improved" ones with the metal insert. They were a tight fit on the motor but I used a socket and hammer. (lightly). Line up the coupling pieces, reattach clips, DONT FORGET THOSE SCREWS HOLDING THE MOTOR CLIPS. Pump goes on next, etc. MAKE SURE ALL WIRING IS RECONNECTED! Cabinet goes back on, large clips holding cabinet to rear of machine go back on. Knob console flipped down and reattached.

Plugged it in and I was good to go! This washer is almost ten years old and this is the second time I have been able to bring it back from the dead, the first time being the agitator "dogs" wearing out. THANKS PARTSELECT!

You will see the coupling on the "spindle" of the motor. In my case, both plastic pieces were cracked in 2 places. I removed the old coupling and cleaned the "spindles" and lightly regreased.

The replacement pieces I ordered were the "improved" ones with the metal insert. They were a tight fit on the motor but I used a socket and hammer. (lightly). Line up the coupling pieces, reattach clips, DONT FORGET THOSE SCREWS HOLDING THE MOTOR CLIPS. Pump goes on next, etc. MAKE SURE ALL WIRING IS RECONNECTED! Cabinet goes back on, large clips holding cabinet to rear of machine go back on. Knob console flipped down and reattached.

Plugged it in and I was good to go! This washer is almost ten years old and this is the second time I have been able to bring it back from the dead, the first time being the agitator "dogs" wearing out. THANKS PARTSELECT!

Parts Used:

-

MARIA from TAMPA, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door was popping open

Watch the video before I received the part. Made it very simple to replace and which screws to take out.

Parts Used:

-

Harry from OTSEGO, MI

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would run, but not spin.

Unpluged washer. Turned washer on its side, unpluged wire harness to motor. Removed hoses to pump on motor, removed screws and nuts holding motor, then pulled out motor. Popped off old couplings,intalled new, reassembled. Piece of cake!

Parts Used:

-

Justin from Ontonagon, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

basket would not spin during spin cycle

Raised washer on cinder blocks high enough to get underneath, removed wiring, capacitor (because it got in the way), removed spring clips from pump, removed pump, no water spillage this way. removed clips from motor, removed motor, pulled old broken coupling rubber ring and plastic pieces out, used a spark plug driver to press new ones in place on the gear shaft and motor as they will fit tighter because they have a metal reinforcement that the original did not have, lined up the two halfs and clipped motor back on, cliped pump back on, reconnected wires again, lowered off the blocks and washed a couple loads that night.

Parts Used:

-

Tim from Apple Valley, MN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!