11027086600 Kenmore Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

F1 code show

-

Bernard from OCOEE, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer entered spin cycle, but would not spin.

The washer would enter the spin cycle, but after starting to spin, would quit, and beep repeatedly. The fault code shown was DL. The manual cited DL as Door Lock malfunction. A check of the door lock switch suggested an internal problem. Sears offered the part at a far greater price, and shipping was several times more than PartSelect.com. PartSelect was chosen, and the part ordered on-line. Within two days the part arrived. Installation was simply a matter of lifting the top of the unit on which the door is supported. IT is done by inserting a narrow screwdriver into the separation, and pressing on the two metal springs holding the top in place. The old part was simple to remove by extracting two phillips head screws and removing the cable from the cable mounts underneath the top surface then threading the cable and plug back through the cable hole. Before that could be completed, the rear cover of the control panel was also removed, and after the plug of the defective switch was removed, the new cable was connected, and threaded back through in the reverse of the removal of the old switch, the phillips head screws, the control panel rear cover and returning the unit top to the resting position and snappin it into place. The Power ON check indicated that the problem fault code was cleared. The unit functions normally with the new switch. Hats off to PartSelect. The part was available in stock, and shipped promptly, and at substantially less cost than Sears.

Parts Used:

-

Paul from Rio Vista, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water pump was busted.

Just pulled the old water pump off and replaced with new one and was good to go. Thank you so much for sharing the problems and how to fix. Dean

Parts Used:

-

William from MAGNOLIA, MS

-

Difficulty Level:Very Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Wrench set

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

replace suspension rods

lifted top using putty knife to push back holding clips.secured top so it did not fall. moved basket to one corner and lifted the spring up, while it was lifted remove the plastic holding rings. Then push down on holding clips that are near bottom of side of basket and the suspension rod just eases out. do that for all 4 and you are done.

Parts Used:

-

Rick from Hamersville, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

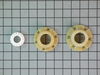

The agitator was making grinding noises

Removed the softener dispenser and cap that's under it. Used 7/17" socket with an 18" long extension to reach the bolt that holds agitator down. Pulled auger off, pulled lower agitator off. Removed the 6 philips head screws that hold basket hub in place. Removed hub and installed new one, replaced screws. Lightly greased spline and reinstalled lower agitator. The auger has the cam section in it. A trick to get the rollers in place is to secure them to the cam with rubber band. Have string tied to the band. Insert the cam and when almose all the way in, pull rubber band off and the rollers stay in place. Reinstalled the bolt, cap and softener dispenser.

Parts Used:

-

Mark from Erie, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

2 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

agitator broke

very easy to repair , instructions very clear , parts person very good to talk to, parts got here fast

Parts Used:

-

Joseph from Kalkaska, MI

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken hinge pin.

-

Kevin from Tucson, AZ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Code F51 Washer would not spin.

I disassembled the top half of the machine removed the drum and found a bad bearing. The code F51 said i had a bad motor control board. I had a frozen bearing on the main shaft. Freed up bearing, machine now runs but I need to replace the bearing,

Parts Used:

-

Fred from Valparaiso, IN

-

Difficulty Level:Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Flashing "F1" Error Code

Had to dig a little to find what error code "F1" really meant. Thanks to the Internet. Paperwork with machine advises to call a technician. Once I discovered what the error code indicated, I followed the instructions and removed and replaced the controller. Although it was expensive I didn't have to pay for any labor. Machine now functions normally.

Parts Used:

-

TK from Hanford, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!

machine gives uneven load alarm and f51 error code

Tilt the machine over to access the bottom I rested it on a dolly.remove the rotor with an allen wrench .then rmove the 4 bolts on the stator .then lift it off the main shaft and unlug the sensor wires . just reverse the process to install the new one (be sure to allign the arrows on the sensor and the stator when reistalling. I wish i could say this solved my problem .my machine runs untill the spin cycle then it starts shaking and gives the uneven load alarm again.

Parts Used:

-

Charles from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

Was this instruction helpful to you?

Thank you for voting!

Water would not drain

I read the directions on this web site and was able to install the new drainage pump in about 30 minutes. I suprised myself. Thanks.

Parts Used:

-

Neil from Onalaska, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench set

Was this instruction helpful to you?

Thank you for voting!

The washer was trying to walk off during the spin cycle.

Well i watched a video on youtube that demonstrated the repair, and it seemed easy enough, so i ordered the parts which arrived quickly enough that we avoided a trip to the laundry mat, very cool! So i did just what they said to do, unplug machine, tape down the lid, use a putty knife to pop the retaining springs in front. I used a long screwdriver to hold up rod on top and then rotate the ball around and let the rod fall through, them i used a yard stick to pop out cup on bottom. I did have assistance holding the drum back so i could see, Then i reversed the process with a new rod. The only reason it took 30 min was i did not put the cups under the balls on top, because it didnt have them in the first place, i decided to put them in after then reading the instructions. The machine runs like new, and my wife is very happy!!

Parts Used:

-

James from Alvin, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

Was this instruction helpful to you?

Thank you for voting!

Washer was noisy and had a lot of movement

The rod kit fixed the issue. I cant really explain how I did it, because I dint know if I did it the right way.

Parts Used:

-

Shawn from Indio, CA

-

Difficulty Level:Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

Was this instruction helpful to you?

Thank you for voting!

Won't drain the water

-

Jose from Verobeach, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Socket set, Wrench set

Was this instruction helpful to you?

Thank you for voting!

Thwe washer continually went off balance and displayed UL code

The instructions displayed the parts location and and some instruction. The top of the unit will release and pivot up after the two catches at the front are presed in at the front seam. The catches are located about 6 inches in from the sides. Before lifting the top though you should secure the lid to the top. I used some masking tape. Pivot the top up and brace the top to prevent it from falling back too far or forward over your work access. I leaned the top back against the wall behind the washer. Once the top was secure I began by lifting one conner of the tub assembly so that a corner dampner assembly could be removed. The top of the dampener assembly has a loop which grabes the plastic cup at the top frame of the washer. Lift the tub assembly (about 30lbs) on one corner and as the hook becomes free rotate the plastic cup to disengage the hook from the cup. To make it easier to work inside the washer frame I used the bar clamp to hold the tub asembly to one side so that I could reach along the damper assembly to pop loose the top retainer at the tub by pushing down with a screwdriver. Once the dampener assembly was loose it can be removed and the new one inserted in its place. I repeated these steps for each dampener and was done in about 30 minutes. You may want to note there is a wire clip on the right rear dampener and this was easily removed and reinstalled on the new assembly.

Parts Used:

-

Richard from Dallas, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

Was this instruction helpful to you?

Thank you for voting!