LSE7804ACM Maytag Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Washer drum not spinning correctly

Drum on the Maytag washer was not spinning is a true rotational pattern. Adjust or replace the centering springs.

How-to-description

I had to hack saw off the centering springs eye bolts since they were rusty and not adjustable. If you have to cut the old eye bolts as I had to, be careful... the spring will jump up an inch or two very quickly and you want to keep your hands clear. It makes a load noise and my wife asked "what happened". Not a big deal, just be aware of the spring returning to a normal state.

Place the new eye bolts in position and tighten the nut with 4 turns. With duck tape I held the eye bolts in place from under the machine. Had my son push the drum towards the replaced spring to shorten the length of the end of the spring to the eye bolt. Stretch the new springs with a long screw driver, one end against the washer body, and the other end near the handle. Pulled down on the scrw driver until the spring can hook onto the eye bolt. Before cutting the old eye bolts I measured the length of the eye bolt from the spring to the frame. Adjust the new eye bolts to the same length after the spring is stretch onto the eye bolt. Overall a simple project, cost $40 for me and the best advice is using the long screw driver to pull down on the springs.

How-to-description

I had to hack saw off the centering springs eye bolts since they were rusty and not adjustable. If you have to cut the old eye bolts as I had to, be careful... the spring will jump up an inch or two very quickly and you want to keep your hands clear. It makes a load noise and my wife asked "what happened". Not a big deal, just be aware of the spring returning to a normal state.

Place the new eye bolts in position and tighten the nut with 4 turns. With duck tape I held the eye bolts in place from under the machine. Had my son push the drum towards the replaced spring to shorten the length of the end of the spring to the eye bolt. Stretch the new springs with a long screw driver, one end against the washer body, and the other end near the handle. Pulled down on the scrw driver until the spring can hook onto the eye bolt. Before cutting the old eye bolts I measured the length of the eye bolt from the spring to the frame. Adjust the new eye bolts to the same length after the spring is stretch onto the eye bolt. Overall a simple project, cost $40 for me and the best advice is using the long screw driver to pull down on the springs.

Parts Used:

-

Paul from Huntley, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

21 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer leaking badly and making loud noise on spin

Determined the tub seal was bad and ordered the seal and tub bearing. Removed the front cover with two phillips screws and unbolted the top to lift back. Removed the agitator with 1/4" setscrew on side and lifted out. Using punch and hammer, broke the inner tub nut loose (clockwise is off). Lifted out the inner tub, unscrewed springs from the bottom and removed; then removed the bearing with a little prying (had to raise the tub slightly and tap the center splined shaft to push out) and lifted out the outer tub. Outer tub had few rust spots about to penetrate, so sanded off rust, primed with etching auto primer and sprayed enamel topcoat to prevent further corrosion. Reassembled in the same order.

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

When done, there was still a loud noise on the spin cycle, so obtained a spin bearing and brake assembly (need to replace both most always). Tilted the machine on its back and removed the pulley, then put a special wrench on the brake assembly and broke loose (counterclockwise) with a 3 foot extension after placing a 2x4 section in the tub between wall and one of the bases for the spring arms (to keep the tub from turning). When the brake came off it was full of water and corroded from the leaking tub bearing previously replaced. Reassembled in reverse order and replaced two belts on the bottom for good measure. Works perfectly now and is very quiet.

In my estimation, the repair should have included both the tub bearing/seal and the spin bearing/brake assy from the outset. Could have used a chain visegrip wrench instead of special tool to remove the brake assy - whatever is available. The tool costs a lot and will never be used again.

Parts Used:

-

Barry from Brooklyn, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Stripped leveler screw making impossible to level my washer

Put blocks under the washer where the leveling leg was needed and screwed the part into the washer. Then it was just a matter of moving the washer into place and leveling. Pretty easy.

Parts Used:

-

Rebecca from Wylie, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Wrench set

21 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer had burning Smell - Start/Run windings problem

** Your best bet is to use a digital camera to take pictures of the various stages as you take apart the dryer - especially the wiring. And, use masking tape to label all the wires.

** I removed the Blower Housing which made the process much easier.

** Find a friend with or buy the snap ring pliers

** Big Secret not mentioned anywhere - the Motor Support (diag. #20) can be removed ! Hence - the entire Motor assembly can be taken out to remove those irascible Motor Clips.

** For the Green ground wire going from the dryer frame to the motor, you need to take the screw from the old motor and use it to screw into a hole marked with a black "slash" on the new motor.

** After 3 days of WD 40 and an allen wrench, I could not remove the Motor Pully from the old motor, so I would buy one if I were you.

** Hardest Parts - Removing the Motor Clips, reattaching the idler spring!, having another person hold the drum while I installed the Belt and reattached the front drum frame thingy, and deciphering my wiring schematic and reassembly diagrams ! That is why a digital camera is so helpful.

** The process is really very easy if you use the suggestions above and read the others.

** Find the "Model Diagram" on the PartSelect website - an excellent resource !!

** A twenty+ year old Maytag - up and running again !! Many thanks to others who shared their story.

** I removed the Blower Housing which made the process much easier.

** Find a friend with or buy the snap ring pliers

** Big Secret not mentioned anywhere - the Motor Support (diag. #20) can be removed ! Hence - the entire Motor assembly can be taken out to remove those irascible Motor Clips.

** For the Green ground wire going from the dryer frame to the motor, you need to take the screw from the old motor and use it to screw into a hole marked with a black "slash" on the new motor.

** After 3 days of WD 40 and an allen wrench, I could not remove the Motor Pully from the old motor, so I would buy one if I were you.

** Hardest Parts - Removing the Motor Clips, reattaching the idler spring!, having another person hold the drum while I installed the Belt and reattached the front drum frame thingy, and deciphering my wiring schematic and reassembly diagrams ! That is why a digital camera is so helpful.

** The process is really very easy if you use the suggestions above and read the others.

** Find the "Model Diagram" on the PartSelect website - an excellent resource !!

** A twenty+ year old Maytag - up and running again !! Many thanks to others who shared their story.

Parts Used:

-

Thomas from Raleigh, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench set

18 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

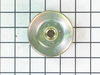

no water drain

removed old pully, put new one on with hex driver, removed belts, put new belts on and finished.

Parts Used:

-

Franz from Lakeland, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer would not fill with water

The trouble-shooting section on this website described the above problem and suggested that the proper course of action was to replace the water inlet valve, which I ordered and replaced. Replacement of this part was quick and easy.

Parts Used:

-

Fredrick from Clinton Corners, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

20 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My washer stopped draining

My washer filled up and wouldn't drain at all.

I tried checking the fuses, then read that the belt could be broken or worn. I checked under the hood and the belt was broken right in two. I drained the washer manually then ordered the new belt.

I was able to replace the belt in no time with no effort at all.

I tried checking the fuses, then read that the belt could be broken or worn. I checked under the hood and the belt was broken right in two. I drained the washer manually then ordered the new belt.

I was able to replace the belt in no time with no effort at all.

Parts Used:

-

Jenna from St. Louis, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

24 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leaking from the underside center of the tub. Only on the rinse cycle.

I want to mention only the difficult parts.

The removal of the retaining ring/nut (which is under the agitator) . After 10 + years, it was very hard to move this part and it was eventually broke it to remove it. WD40 was used but not effective (to much calicum build up). You must turn the cone shaped piece (located under the inner tub) clock wise to get it to remove. A spanner wrench was not used to remove this. I used a punch and a tack hammer. We could not remove the old tub bearing (closest to the shaft), so we just cleaned it up with emory cloth and used the new tub seal/outer bearing. Spins great but have not been able to check the water leakage problem yet.

Caution: there are two dark colored ring (very thin) that go back on top of the rubber collar. These must be reused. These are hard to see. I pushed the old tub seal/bearing out with the end of a 2x4 (very slowly and carefully). I put the tub up on two of the 2x4's, for clearance off of the floor and used the third to knock the old bearing out. Old machine are very messy.

The removal of the retaining ring/nut (which is under the agitator) . After 10 + years, it was very hard to move this part and it was eventually broke it to remove it. WD40 was used but not effective (to much calicum build up). You must turn the cone shaped piece (located under the inner tub) clock wise to get it to remove. A spanner wrench was not used to remove this. I used a punch and a tack hammer. We could not remove the old tub bearing (closest to the shaft), so we just cleaned it up with emory cloth and used the new tub seal/outer bearing. Spins great but have not been able to check the water leakage problem yet.

Caution: there are two dark colored ring (very thin) that go back on top of the rubber collar. These must be reused. These are hard to see. I pushed the old tub seal/bearing out with the end of a 2x4 (very slowly and carefully). I put the tub up on two of the 2x4's, for clearance off of the floor and used the third to knock the old bearing out. Old machine are very messy.

Parts Used:

-

Mark from King George, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

19 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Machine would shake violently while tub was spinning

I followed the supplied directions to remove covers, unbolt tub springs, and expose the area needed to replace the damper pads. I cleaned the area with acetone and applied a rubber adhesive (not supplied). I used tire patch compound because that is what I had on-hand. I positioned the pads and after they had dried 1/2 hour, lubricated them with the supplied grease. I reassembled the washer and it is now smooth and well behaved.

Parts Used:

-

Gary from Alhambra, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

16 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud rumble in dryer. Blower wheel broken.

First I unplugged the machine. I removed the two screws in the front panel and tilted the bottom of the panel out unclipping it at the top. I removed the lint duct whichis held in place with several 1/4" hex head screws. Then I removed the blower cover, also held on wth 1/4" hex head screws, exposing the blower wheel. Using snap ring pliers I removed the snap ring at the end of the motor shaft. Using needle nose liers I removed the spring clamp around the center hub of the old blower wheel and pull the blower wheel off the motor shaft. After cleaning as much lint out as I could I put the new blower wheel on the motor, secured with spring clamp and snap ring. Then I put the blower cover and lint duct back on and put front panel back on.

Parts Used:

-

Ernest from York, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

16 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Clothes were not drying, three hours still damp

Followed the instructions on the video, and saved 500 hundred dollars. I was already shopping for a new dryer. Thanks so much!

Parts Used:

-

STEVEN from BELLEROSE, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

16 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

lint on clothes

replace lint filter under agitator, remove 1 screw, lift out agitator and replace filter screen.

Parts Used:

-

gene from longmont, CO

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

22 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Main drive belt worn

Tilted the machine back on a 45 degree angle while a friend held it tilted I grabbed the pump belt and removed it and then removed the main drive belt by turning it and derailing it off track . but the new belts on using a reverse technique by rerailing the new belts on to the pulleys. pushing the main motor away from the spring tension made it easier . very simple staight forward job. similiar to putting a chain on a bicycle!

Parts Used:

-

Stephan from Yonkers, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

20 of 30 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Original problem: Blower fan came loose from the motor shaft.belt and was making a noise clothes were slow drying. Second problem appear upon inspection: idler pulley bracket shaft severely worn.

Replacing the blower fan took way too long, like 4 hrs, because I didn't know how to disassemble the dryer and get to the problem. Replacing the idler bracket and assorted retaining rings and washers was fast, something like 1 hour. Disconnect the power cord, exhaust hose, and gas line. Remove two screws at the bottom of the face of the machine, unplug the electrical harness to the door light, switch and ground and remove the front of the machine. Remove the access panel at the back of the machine and remove the belt from the idler pulley. Remove the four screws holding the front drum support assembly and remove the drum. Replace some old retaining rings and the spring washers on the drum support rollers. Around back assemble the idler pulley assembly with some new washers and the old roller which seemed in good condition. Put it all back together. About one hour.

Parts Used:

-

adriel from sylmar, CA

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

17 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would grumble(hint the grumble lingered for a second or two after shut down)

Unplugged the dryer!!!! Removed two screws from lower front panel. Pulled bottom of front panel forward which allowed clips holding top of panel to release. Unlcipped wires attached to door switch on front panel. Set aside front panel. Removed 4 screws(2 on left & 2 on right) from the drum retainer ring. Set aside retainer ring. Removed thin metal cover protecting blower wires. Removed several screws holding blower cover. Note blower is located on lower left below the lint screen. Used snap ring pliers to remove snap ring securing old blower wheel(an external snap ring). Removed old blower wheel from motor shaft. Inserted new blower wheel on motor shaft. Replaced snap ring. Replaced blower cover. Replaced thin metal wiring cover. Replaced drum retainer ring. Reconnected door switch wiring. Replaced front panel. Done. A hint on the maytag dryer. If your drum wiggles out too far the belt on the drum might not stay aligned. There is a groove on the drum...the belt should NOT sit in this groove...it should ride on the drum about an inch in front of the groove!!!

Parts Used:

-

Richard from Cary, NC

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

14 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!