DG106 Maytag Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Door safety switch would not close keeping dryer from running

Shut off or unplugged dryer for safety.

Slipped thin blade putty knife up under bezel of switch to unlatch from the panel and pulled forward to remove the swwitch from the dryer. Unplugged the quick connect terminals (3) from the old switch and plugged them onto the new switch. one of the terminals had gotten quite hot and darkened the insulation so it was replaced with one that was supplied with the switch. that was a cut, strip, crimp process. Placed the new switch into the panel and snapped into place.

Slipped thin blade putty knife up under bezel of switch to unlatch from the panel and pulled forward to remove the swwitch from the dryer. Unplugged the quick connect terminals (3) from the old switch and plugged them onto the new switch. one of the terminals had gotten quite hot and darkened the insulation so it was replaced with one that was supplied with the switch. that was a cut, strip, crimp process. Placed the new switch into the panel and snapped into place.

Parts Used:

-

John from Warsaw, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

9 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Blower fan was broken and spinning on the motor shaft

Removed front cover, removed housing cover, took old fan off, installed new fan, put covers back on.

Your instructional video was very helpful. He told which screws to remove to get the covers off. I was unsure about how access the fan until I watched. Well done!

Your instructional video was very helpful. He told which screws to remove to get the covers off. I was unsure about how access the fan until I watched. Well done!

Parts Used:

-

Roger from Owatonna, MN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door switch broke

remove bottom section under door 2 screws remove door 2 screws remove switch by squeezing tabs install 2 new female ends on wires supplied with switch . put switch back in plug in wires .

Parts Used:

-

richard from pleasant valley, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

9 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Timer wouldn't shut dryer off

Removed the back of the control panel. Made note of wiring and disconnected same. Pried off center of dial with screwdriver. Removed circlip with needle nose pliers and removed dial. Removed two screws with nut driver and removed timer. Installed new in reverse order.

Parts Used:

-

Larry from Jacksonville, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud squelling noise when dryer was running.

I had to remove the drum. 1. remove lower panel. 2.remove the vent duct. 3.Remove the door (be sure to mark the door switch electrical wire with tape NO, NC, COM). the switch is marked. 4 Slacken the drive belt by removing from its idler pulley. 5.Pull the drum forward & out, by lifting the top without removing it (may have to struggle a bit by bending the sides of the dryer outward). 6.Large 3/4" socket remove the squrrel cage fan counter clock-wise. 7.Unplug the wire harness to the motor and with a large flat bladded screw driver push the spring clamps down & out-ward to remove them.

I always take pictures with my digital camera before removing a part so when I reinstall the part if a question of position or what went were I have it documented in my camera to view.

I install the belt and use scotch tape to hold it in place before I reinstall the drum.

The best part was being able to access the interior of the dryer to clean the lint out.

I hope this helps!

I always take pictures with my digital camera before removing a part so when I reinstall the part if a question of position or what went were I have it documented in my camera to view.

I install the belt and use scotch tape to hold it in place before I reinstall the drum.

The best part was being able to access the interior of the dryer to clean the lint out.

I hope this helps!

Parts Used:

-

Robert from Vacaville, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Gas dryer not heating

Thank you very much for your prompt service. This was so cool... On Monday night my wife told me the dryer was not heating. I did a basic diagnosis, checked the internet for parts and lowest price and found your site. I ordered the part I thought I may need and 2 days later the part arrived and the dryer is working again.

Way to go, PartSelect!

Way to go, PartSelect!

Parts Used:

-

Joe from Madison, WI

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer got hot then heat would shut off

Sensor is in the front lower left. Gas off, electicity off. Removed two screws for the filter, pry/lifted the top up and taped it too the overhead cabinet, removed two screws inside top of front panel, lifted pandel with door closed staight off. Two screws to remove the flame sensor braket. unplug the old sensor install the new one and reverse everything. With others suggestions I purchased temperature switches etc. but the radiant flame sensor was the problem. I now have some spare switches for future. Excellent company and very quick service. Oh, Sears wanted 200.00 just for the service call, I live rural.

Parts Used:

-

Douglas from Fernley, NV

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After the first flame the flame would not come back on

Turned out to be the primary coil on the gas valve. If you remove the cover of the coils and wait for the dryer to try to start the flame the coils are energized, a magnet is turned on. By lifting the coil you should feel the magnet if the flame is on. If the flame does not come on after the ignitor fires check to see if the coils are energized. If not buy the set, it's cheaper then purchasing them separately.

Parts Used:

-

Frederick from Tinton Falls, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Trying to install the drum belt by reaching in from the front over the top of the blower & motor.

I observed that the top of the dryer was affixed by two screws at each front corner. With these removed the top of the dryer could be easily lifted and with the front support panel removed the drum, drive motor and idler pulley could be accessed. This allowed the installation of a new drum belt in a short period of time. Installing the belt from the front lower left hand side proved very difficult for me but with the top raised and coming in from the top it was accomplished in short order. Thank you, Wesley Harmon

Parts Used:

-

Wesley from Tulsa, OK

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench set

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

missing, probably broken female latch part

-

claude from laguna niguel, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not stay closed.

I used a flat screw driver to pop out the old female portion and snapped in the new one. Dryer stays shut. That's it!

Parts Used:

-

karl from monroe, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken drum belt

I pulled the face of the dry off by removing the two screws on the lower face below the door. I pulled the drum out by removing the two bolts holding the drum mounts to the frame. I put the new belt around the drum and remounted it. The access hole on the lower right corner on the back of the appliance allowed me to turn the drum to align the belt (and turn it right side up) with the pulley. It took a moment to figure out how to re-thread the pulley but was able to do it after only a couple of tries. All in all it was quite easy!

Parts Used:

-

Robert from Finland, MN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

8 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

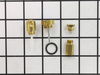

Conversion from natural gas to liquid propane

By following the directions included with the kit it was fairly clear. The diagrams of the control valve was helpful. It would have helped to tell which screws to remove to access the valve and where the screw was that retained the burner assembly.

Parts Used:

-

Scott from Fairfield, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

noisy

-

Hazel from CONNERSVILLE, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set

7 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Drum would not spin to drain water

Removed two screws and lifted the control console then tilted forward the shell. Removed two screws holding the latch cover and assembly then disconnected two wires. I played with the assembly until I discoved the element was toast. Ordered the part but when I got it I was confused because it had three prongs (two on one side and one on the other) when the burnt one had only one and one and I only had 2 disconnect wires. I thought I had gotten the wrong part but figured it out. Actually putting the assembly together was the easy part, trying to get the outer shell back together was a little tough. Between taking it a part, figuring out what was wrong and ordering and receiving the part was about three weeks. So when putting it all together took awhile but I did it and it works great.

Parts Used:

-

Gay from Apple Valley, CA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

9 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!