CFLE1011MW0 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Zipper was cought between brum and cabnet

Disconect power, Removed top and front of dryer.

The broken zipper was easly removed at this point. The plastic glides easly snap out and in. The felt took some more time to scrape off and clean the old glue. Glue the new felt into place and replace front and top. The parts were shiped promptly and the dryer was out of service for only three days.

The broken zipper was easly removed at this point. The plastic glides easly snap out and in. The felt took some more time to scrape off and clean the old glue. Glue the new felt into place and replace front and top. The parts were shiped promptly and the dryer was out of service for only three days.

Parts Used:

-

John from Swansboro, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squeaking in dyer progressively got unbearable

removed top and front panel on stackable dyer unit. 3 screws at back of the inside of the drum, and the drum was out. installed new bearing and belt and all was good.

Parts Used:

-

matt from south vienna, OH

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

female part of door clasp broke

-

Tammy from St. Peters, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squealing

Customer responses / directions were great nothing to add - except no where does anyone mention "high temperature grease" for the Drum Support Bearing - only on the video is it mentioned numerous times. I honestly think it took longer to vacuum out all the lint then it did to do the repairs.

Parts Used:

-

Diane from MADISON, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

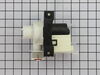

Pump motor made humming noise and wouldn't drain water from tub.

Disconnect power. Disconnect water hoses. Remove back panel. Remove top panel. Disconnect bladder ring. Disconnect control panel wire harness and control panel. Remove front panel. Disconnect hose clamps to drain hose and tub drain hose. Disconnect pump motor power supply wire. Disconnect pump screws. Now do everything in reverse replacing old pump with new.. One special note: replace factory hose clamps with new hose clamps.

Parts Used:

-

Matthew from Oakford, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaky drum until drum would not turn.

Watched on-line video, then applied those steps.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

1. Pop the front of the deck loose using putty knife to depress clips;

2. Disconnect wires from light and door switch;

(Before I disconnected wires from door switch and light, I made wiring sketches to make sure I reconnected in original manner.)

3. Remove lint filter mount screws and mount from bottom of door opening;

4. Cut drum belt with wire-cutters and removed it;

5. Remove drum support clip from top center of front panel;

6. Remove (1) screw from each side of dryer body that hold front to sidewalls, removed front panel;

7. Remove drum by lifting the rear out of the bearing, then moving it forward through the machine front;

[While I had the dryer disassembled, I thoroughly cleaned it of lint, dirt & metal filings. The metal filings were from the worn ball hitch and drum support bearing cup. I spent as much time cleaning it out as I did working on it.]

8. Stand drum on gallon paint bucket while removing ball hitch (Use a #2 drywall phillips apex to obtain sufficient seating & torque to remove and reinstall ball hitch screws at rear of drum.);

9. Have a second person hold the new ball hitch in position while starting screws, if necessary;

10. Use nut driver w/5/16" socket to remove bearing retainer & ground ball clip;

11. Install new bearing into retainer clip, insert attachment screws through the holes in both, stick grounding ball in depression on back of bearing as screws are fed through back panel;

12. Hold ground ball clip in place to start one screw, then the other & tighten with nut driver;

13. Start drum belt on motor shaft and position against tensioner pulley;

14. Feed drum through front of machine and loop belt over rear of drum;

15. Slide belt forward on drum as drum moves to rear to keep it aligned with position of tension pulley;

16. Lift rear of drum to place ball hitch on top of bearing, then press down to seat it into bearing;

17. Turn drum to ensure belt alignment, then re-accomplish steps 6 thru 1.

Parts Used:

-

Doug from ODESSA, TX

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Black lines and small tears

Previous comments on line were so helpful.

My husband and son took the dryer apart by removing the top in order to get to the drum. Part of silver rim that the Drum Glide is attached to was broken,it had been cut somehow. They had to soder it back in place so they could attach the Drum Glide and so far it's working.

Felt- I just ordered one with the adhesive and removed the damaged section used a wire brush, applied the adhesive ( which was more than enough) waited a few minutes for the adhesive to set, applied the felt, attached binder clips to hold it in place while working on the Drum Glide. Really easy.

My husband and son took the dryer apart by removing the top in order to get to the drum. Part of silver rim that the Drum Glide is attached to was broken,it had been cut somehow. They had to soder it back in place so they could attach the Drum Glide and so far it's working.

Felt- I just ordered one with the adhesive and removed the damaged section used a wire brush, applied the adhesive ( which was more than enough) waited a few minutes for the adhesive to set, applied the felt, attached binder clips to hold it in place while working on the Drum Glide. Really easy.

Parts Used:

-

Robin from Sewaren, NJ

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squeaking c/c unlevel. Led to shaft breaking

Took off all controls and panel. Removed the top. Pulled out the drum. Unscrewed shaft and bearing holder. Replaced all parts and started it back up.

--The parts were shipped timely,

--The parts were shipped timely,

Parts Used:

-

Chad from Reisterstown, MD

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud Squeek while the dryer is running.

1. After checking the Parts Select website for some useful information I unplugged the dryer.

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

2. I popped the two clips holding the top down and lifted the top up and out of the way.

3. I used the 8mm socket and screwdiver combo to remove the two screws holding the front of the dryer on. These screws are so close to the sides of the dryer that you need something very thin to seat the socket, it is so thin a small rachet would not fit.

4. Once the to screws are free to forget to unhook the two wires that lead to the automatic cutoff switch on the right. Label them and move them out of the way.

5. The front of the dryer should pivot forward and come right off. Don't forget about the two clips at the bottom, they are not really attached to anything and can be easy to lose.

6. Get your screwdriver and dive into the drum, on the back should be three screws, take those out.

7. Spin the dryer around and take off the vent cover in the lower left corner of the back of the dryer, watch out the socket is a smaller size.

8. Once inside there is an idler pulley like on the back of a ten speed bike, pull the tension out of it and take the drive belt off the pulleys.

9. The drum should be able to be pulled out the front of the dryer, set aside with the door. The screws on my dryer were so tight I had to use a hammer drill to remove them.

10. This is were I got stuck, no one mentioned how to get the bearing plate off, as if everyone would just know. You must lift up on the bearing plate and once it moves up then you can pull it out.

11. Use the 8mm socket to unscrew the old plastic bearing guide. The small metal clip on the back of the dryer will fall off with the grounding ball bearing.

12. With brum bearing kit in hand start off by putting as much high temp lubricant as you can into the bottom of the new bearing guide. I also use a little lubricant like glue to hold the new grounding ball bearing in the little hole on the back of the bearing guide.

13. Here is the tricky part you have to screw the bearing guide into the the dryer while simulaneously holding the little metal clip in place on the back of the dryer. I used duct tape to hold the metal clip and once the screws got started I just took the tape off.

14. Now you have to do the impossible, the bearing must be screwed to the drum. So unless you have 7 foot long arms you can't hold the bearing and drive the screws. Another problem is the bearing itself, the holes are not the same size as the original and they are not threaded. I stripped every screw that came with the kit trying to get them through the metal of the bearing.

15. With an unwilling victim holding the bearing steady I finally got a replacement screw to seat through the bearing. Once you get one the rest are easier.

16. You are ready to reassemble, after vacuuming everything ou, pick up the drum making sure the belt is around the drum about where it was when you took it off. Push the drum through the front of the dryer all the way to the back, aim a little high so the bearing can move down and seat in the bearing guide.

17. Tuck the clips on the front panel of the dryer into the bottom front edge of the dryer and the whole front should pivot up, when you get it almost closed you will have to lift the drum and set it on the front bearing in the door.

18. While holding the front of the dryer on you have to reach inside and get the 8mm screw started on the left or right, if you let go the front of the dryer will pop off and you have to start over with the pivot. Now is a good time to have a magnet on a stick so when you drop the screw or screw driver you don't have to take the front off to retrieve your tools.

19. Once the front is on reconnect the two wires to the switch in the front of the dryer. Remember the ones you were supposed to have labeled earlier.

20. Close the top of the dryer and spin the dryer around so you can reach inside the vent door and pull the tension pulley over and reseat the drive belt. Rem

Parts Used:

-

Miles from LaPorte, IN

-

Difficulty Level:Very Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

3 of 3 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Front drum guidesnubber ring was worn out

removed the top of dryer, pulled front panel back from drum and installed snubber(Front Drum guide).

Parts Used:

-

Alan from Emporia, KS

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

clothes were getting stuck

after numerous holes put in my families clothes i looked on line and found "partselect.com". i ordered the front drum glide after seeing a similar story about the clothes being torn and getting caught and my family and i have our new dryer back!! yeah :<)

Parts Used:

-

robert from lake worth, FL

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leveling Leg Broken

The leveling legs on my Frigidaire stackable washer & dryer were broken. They are made of plastic and while moving the unit one of the legs had broke off. I ordered two replacements from PartSelect and received them within a few days. The old legs were removed by screwing them out and then the new ones were installed. Pretty easy installation for DIY. The new legs work great.

Parts Used:

-

Brian from Rochester, NH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Wrench (Adjustable)

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking hoses

I made my job difficult by removing the back panel, then the side, and finally discovered the front panel opens giving access to the washer. Using heavy pliers I removed the spring clamps and replaced the pump to washer hose and the other hose end to the tub. Turned on the washer no leak only to discover the drain hose had developed a leak. So I ordered the second hose. I was not sure how to release the plastic retaining clamps. Finally just yanked them loose, which worked. Ran the hose through the machine out the back into the drain pipe. I was able to reattach the retaining clamps put the spring clamp on the pump end of the hose. The difficult part was getting the back, sides and front of the washing machine together that took hours.

Parts Used:

-

Dixie from STRANG, OK

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Pliers, Screw drivers

3 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no filter

-

Luis from La Jolla, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

4 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not heating

UNPLUG DRYER (this is key) Removed the top of dryer. used screwdriver and pliers to remove two screws and electrical connections then reinstalled new part stick the magnet behind the part to the back of the dryer to help control the small screws.

Parts Used:

-

Steve from COVINGTON, KY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

2 of 2 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!