CDE4205AYW Crosley Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Drying time was taking longer than it should.

I simply went on line and ordered the part. I had it shipped to my office since I am here all day, M-F. I received the part in 2 days. I took it home, pulled out the old lint filter and slid in the new one. It is amazing how much more efficient my dryer is. The old lint filter had about a 6 inch tear in it so it was not catching all the lint.

Parts Used:

-

Vicki from Springfield, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Baffle broke off and rear felt seal was pulled out

1. Remove 2 screws that hold door hinges on.

2. Remove 2 screws on opposite side of door hinge and remove 2 plastic clips.

3. There are 2 hex screws that hold the front panel on. Remove these and the panel is held on by a flex clip. Gently twist the top towards the outside of the dryer and they will come free.

4. tilt panel forward and lift of 2 clips at the bottom.

5. Remove the screws under the cover panel which will release the drum holder and lint collector.

6. Lift top of dryer and lift out drum.

TAKE THE TIME SINCE THE UNIT IS OPEN TO VACUUM OUT THE ENTIRE DRYER. CLEAN OUT THE EXAUST TO IMPROVE EFFICIENCY AND SAFETY.

7. I replaced the rear felt by using a flat head screwdriver to lift tabs and install felt. Using the screwdrive I compressed the tabs to hold the felt.

8. The baffle was installed inside the drum and using 2 hex bolts to hold the baffle in. I added 2 washers since the hole was inlarged due to the baffle becoming loose and pulling through the metal drum.

9. Re-install the drum and push rear felt to the outside of the drum.

10. The front drum needs to be installed. Push the felt to the outside of the drum and check the rear felt to ensure it is still on the outsid of the drum. Install 4 hex screws to secure front drum holder.

11. Insatall lint catch unit with 4 additional hex screws.

12. Verify the lint collection panel lins up with the exhaust fan at the base. When units line up tighten all 8 hex screws.

13. Reinstall front cover panel by inserting panel on bottom clips and tilt up to the dryer. The top corners are gently twisted to the outside of the dryer to reattach to the spring clips. Use 2 hex screws to attach panel.

14. Re-attach plastic clips and 2 screws on side opposite of door hinges.

15. Re-attach door hinges with 2 screws. Cleck to ensure the door closes.

16. Check dryer operation.

2. Remove 2 screws on opposite side of door hinge and remove 2 plastic clips.

3. There are 2 hex screws that hold the front panel on. Remove these and the panel is held on by a flex clip. Gently twist the top towards the outside of the dryer and they will come free.

4. tilt panel forward and lift of 2 clips at the bottom.

5. Remove the screws under the cover panel which will release the drum holder and lint collector.

6. Lift top of dryer and lift out drum.

TAKE THE TIME SINCE THE UNIT IS OPEN TO VACUUM OUT THE ENTIRE DRYER. CLEAN OUT THE EXAUST TO IMPROVE EFFICIENCY AND SAFETY.

7. I replaced the rear felt by using a flat head screwdriver to lift tabs and install felt. Using the screwdrive I compressed the tabs to hold the felt.

8. The baffle was installed inside the drum and using 2 hex bolts to hold the baffle in. I added 2 washers since the hole was inlarged due to the baffle becoming loose and pulling through the metal drum.

9. Re-install the drum and push rear felt to the outside of the drum.

10. The front drum needs to be installed. Push the felt to the outside of the drum and check the rear felt to ensure it is still on the outsid of the drum. Install 4 hex screws to secure front drum holder.

11. Insatall lint catch unit with 4 additional hex screws.

12. Verify the lint collection panel lins up with the exhaust fan at the base. When units line up tighten all 8 hex screws.

13. Reinstall front cover panel by inserting panel on bottom clips and tilt up to the dryer. The top corners are gently twisted to the outside of the dryer to reattach to the spring clips. Use 2 hex screws to attach panel.

14. Re-attach plastic clips and 2 screws on side opposite of door hinges.

15. Re-attach door hinges with 2 screws. Cleck to ensure the door closes.

16. Check dryer operation.

Parts Used:

-

Al from Newark, DE

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old latch broke

-

Jim from Germantown, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

All three baffles fell out of dryer drum; one by one in a week time span; of course the warranty expired in May of 2007. Figures!

Had to remove the dryer door and back top screws to access the drum.

Once this was accomplished all that had to be done was to turn the drum by hand and replace each baffle and (two) screws each.

Once this was accomplished all that had to be done was to turn the drum by hand and replace each baffle and (two) screws each.

Parts Used:

-

Sandra from Germantown, TN

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door safety switch would not close keeping dryer from running

Shut off or unplugged dryer for safety.

Slipped thin blade putty knife up under bezel of switch to unlatch from the panel and pulled forward to remove the swwitch from the dryer. Unplugged the quick connect terminals (3) from the old switch and plugged them onto the new switch. one of the terminals had gotten quite hot and darkened the insulation so it was replaced with one that was supplied with the switch. that was a cut, strip, crimp process. Placed the new switch into the panel and snapped into place.

Slipped thin blade putty knife up under bezel of switch to unlatch from the panel and pulled forward to remove the swwitch from the dryer. Unplugged the quick connect terminals (3) from the old switch and plugged them onto the new switch. one of the terminals had gotten quite hot and darkened the insulation so it was replaced with one that was supplied with the switch. that was a cut, strip, crimp process. Placed the new switch into the panel and snapped into place.

Parts Used:

-

John from Warsaw, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

9 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer made loud screeching noise.

After reading all the other repair stories on Partselect, by the way thank you all, I removed the door, then removed the two security hooks that hold the top secure. Then I removed the front panel. I then marked all the screws on the outer door and shroud so I could easily put it back together. I left the all the wires connected and set the shroud and outer door to the side and removed the drum belt and drum. Removed the spring off the idler arm, then using nutdriver, removed the screw that secures the idler arm to the motor. Assembled the new idler arm parts and reversed the process to put it all back together. If I would have replaced the idler arm assembly the same time I replaced the drum support rollers, I wouldn't have had to do this twice! But now I am an expert repair tech on this particular model.

Parts Used:

-

Gene from Virginia Beach, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wasn't heating sufficiently/consistently.

Removed front cover, removed old heating unit, installed new thermostat,heating coil inside the dryer and finally replaced the fuse in the front. The main complication was reaching the screws for the heating coil, not really complex.

Parts Used:

-

Kathy from Lilburn, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Socket set

8 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat, coil wasnt getting hot

took old one out then i had to strip the connector off new one was to big...

Parts Used:

-

matthew from Central Islip, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

9 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer ran hot

Took off door, then removed front of dryer to access the internal controls. Project went pretty darn well

Parts Used:

-

Larry from Swanton, OH

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

7 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

door switch broke

remove bottom section under door 2 screws remove door 2 screws remove switch by squeezing tabs install 2 new female ends on wires supplied with switch . put switch back in plug in wires .

Parts Used:

-

richard from pleasant valley, NY

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

9 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Will not start all lights on,makes a ping sound on the control panel when you push the start button

Replaced thermal fuse and replaced door switch

Parts Used:

-

james from CAMBRIDGE, MN

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Terrible sqeel as dryer rotated.

A year or so ago I replaced one drum wheel. The dryer worked fine for months until it started sqeaking again. When I removed the wheels again the shaft was no longer round but half moon shaped. this allowed the drum to drop lower than it's supposed to. consequently the drum ate through the back drum support. I replaced the back drum support and the roller shafts, in addition to two new rollers. It works great now. The more difficult part of the repair was replacing the rear drum support. It is screwed in from the back and requires two people. Everything else I did by myself. The lesson: If you replace the rollers, be sure the roller shafts are not worn. An asymetric shaft eventually causes more parts to wear out.

Parts Used:

-

RODNEY from Spokane, WA

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

6 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

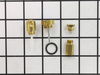

Conversion from natural gas to liquid propane

By following the directions included with the kit it was fairly clear. The diagrams of the control valve was helpful. It would have helped to tell which screws to remove to access the valve and where the screw was that retained the burner assembly.

Parts Used:

-

Scott from Fairfield, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

rodent entry through vent,chewed parts,(distroyed).

Removed the door and machine front.replaced old duct assembly with new ,and reassembled front.

Parts Used:

-

Robert from Menomonee Falls, WI

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

14 of 32 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Heating Element was starting to fail

It was very simple. I removed the fromt cover on the dryer. The heating element was easy to get to and after removing all the attached wires and 4 nuts. The new element was installed, reattached the wire correctly and put the screws back in place. It was extremely easy to complete.

Parts Used:

-

Timothy from Loganton, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!