7761A-71 Norge Dryer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Loud screeching metal to metal sound. The roller and "axle" were worn out.

First I disconnected the power cord. Next the top of the dryer was easily popped upen with a screw driver by inserting it between the top panel and the front door panel. I removed the two sheet metal screws that held the door panel on the upper right and left sides. The door panel was easily lifted up and out and set it to the side (the door switch can stay connected, the wire is long enough). d I pulled the drum out from off of the rollers that hold the drum in place. No need to remove the belt, it stays in place. I reached through the drum and removed the two hex-head screws that held the roller in place ( I only replaced the left one) and added the new one. I pushed the drum back in place over the rollers (it snaps in place). I propped the drum up with a short screw driver to raise it off of the right and left drum glides (on the bottom). I replaced the felt pads and the plastic glides and set the drum back in place. I also replaced the felt ring (seal) that circles the door opening that the drum also glides on. I glued it in place in spots (with gasket glue). It folds back over itself and forms a double thick pad. You will see what I mean when you see how the old one looks. I replaced the front door panel and snapped the top panel back in place. I let the dryer set over night so the glue would set up. I turned it on the next morning and it is as quiet now as when it was new. Oh ...Jay (the husband) did the work not Jean the wife (her dryer, her credit card)

Parts Used:

-

JEan from Cypress, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pull out lint screen holder broke

used a flat blade screw driver to open top up(like a car hood) then removed two screws that held the front panel on. Two more screws held the lint colector part in place. The only problem that I had was that I had to use Elmers white glue to hold the gasket that ran around the lint colector in place.Just a little dab, not enough to soak it.When I took the part out there was about a volleyball's worth of lint in the fan blower. Ordered the part and 2 or three days later I had it. If I need another part I will be back...

Parts Used:

-

steve from madison, WI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Lint screen assembly holder had broken

First I removed the 2 screws located on front panel securing dust collector in place, then I removed the two screws on the side of the dryer that secure the front panel. I also "popped" the top

of the dryer from the front panel. The front of the panel was then detached from the dryer. I thenpulled the gasket away from the collector, removed the old one and installed the new collector. Part of the kit also contained a new gasket to the exhaust duct, I merely removed the old gasket and installed the new one.. All this was notas hard asit sounds. The diagram from PartsSelect site helped

of the dryer from the front panel. The front of the panel was then detached from the dryer. I thenpulled the gasket away from the collector, removed the old one and installed the new collector. Part of the kit also contained a new gasket to the exhaust duct, I merely removed the old gasket and installed the new one.. All this was notas hard asit sounds. The diagram from PartsSelect site helped

Parts Used:

-

George from Vernon, CT

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

7 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

no heat

removed screws (3) holding console face...then lowered console. removed timer dial knob accessing machine nuts (2) holding timer in place. removed timer and transferred all spade connections, wire-for-wire. removed old timer resistor assembly and replaced with new. reassembled everything and tested with one very wet old sock. success.!!!!

smiled and finished martini on the patio.

smiled and finished martini on the patio.

Parts Used:

-

walter from pittsburgh, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Screw drivers

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer did not run at all

removed heating element, thermostat, and then replaced fuse. sorry, the control thermostat was not the problem. it was the fuse kit that failed. the control thermostat would have been easier to replace.

Parts Used:

-

Ronald from Jacksonville, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

11 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Rattling sound at front of the dryer and noticable longer time to dry clothes

The hardest part of my repair was to move all the stuff (sh**) that had accumulated around the machine. We have had our Maytag dryer for 10+ years and a lot of things have been stacked or piled near it. Once the dryer was pulled out and the top could open, it was a matter of disconnecting the door light switch (just remove from clamp and pull out of the way),15 screws, 1 snap ring and a spring clamp. removal was simple, however installation was slightly harder because the new blower wheel's opening for the motors arbor was very tight. I had to use a hammer to drive it on the arbor, no hard hits but to hard to slip on. then another 10 mins to vaccum out all the lint. all together from start to finish was about 40 mins. If you have done any home repairs this job will be simple, hope this helps

Parts Used:

-

Michael from Stockton, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old latch broke

-

Jim from Germantown, WI

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

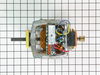

Dryer Quit running

First off I want to say I ordered my motor on Sunday night at 11:30 PM on veterans day and got the two day delivery. My part was sent out on that Monday (fed. holiday) and I received it Tuesday around 1:00 pm after I disconnected the wiring harness, took the blower fan C-clips off, unscrewed about 6 screws, and pulled the assembly apart I just done everything in reverse and replaced the new motor. I discovered that my thermostat fuse was blown so I ordered the High temp thermostat kit from here (two day delivery) on Wednesday at 10:30 PM and got the parts Friday at around 2:00 PM. After taking out four screws and four wires I replaced the fuse and high temp. set, pushed the start button to see if it worked and it started up like new. Now it heats twice as fast and everything doesn't have a light burnt smell. So dry time is faster (no more 80-90 min. cycle times), less dryer sheets (to cover smell) and all this added up to cost savings on electric bill and dryer sheets. It took a week to get my dryer back (because I just looked at the motor) but in the end I needed the fuse and motor. The quick turn around time to get the parts, the pictures to see if I had the right parts, and the ease of ordering the parts meant only one run to the laundry mat, and that wouldn't have happen if the dryer hadn't messed up on laundry day.

Parts Used:

-

William from Marion, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

blower wheel broken

unplugged the dryer.

opened it up.

unscrewed the housing that was holding the blower wheel.

removed the broken blower wheel.

placed the blower wheel on the shaft.

got a socket wrench and an extender to tap the blower wheel into place. I put a towel over the socket wrench so as to be gentle on the blower wheel. I tapped it down until I could fee the grove on the shaft where the washer used to go to hold in the old blower wheel (the new one has enough grip on its own to stay put).

put the housing back on after doing a few spin tests to make sure the blower wheel was spinning freely.

did some spin tests after putting the housing back on.

reassembled the dryer, plugged it in.

turned it on to test again.

done.

opened it up.

unscrewed the housing that was holding the blower wheel.

removed the broken blower wheel.

placed the blower wheel on the shaft.

got a socket wrench and an extender to tap the blower wheel into place. I put a towel over the socket wrench so as to be gentle on the blower wheel. I tapped it down until I could fee the grove on the shaft where the washer used to go to hold in the old blower wheel (the new one has enough grip on its own to stay put).

put the housing back on after doing a few spin tests to make sure the blower wheel was spinning freely.

did some spin tests after putting the housing back on.

reassembled the dryer, plugged it in.

turned it on to test again.

done.

Parts Used:

-

Aaron from Santa Rosa, AL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Part cracked and clothes were getting caught

First I removed the screws that held the part in place, but this proved to be the hardest part for me. I had to find the right kind of screw driver . It was not a slotted or Phillips. It was more star shaped. Once I had the right tool, the rest was pretty easy.

I then opened the top of the dryer to be able to lay the front on the floor. There were wires connected to the front, however, so I had to remove the part that the wires were connected to by slipping it out of the bracket that held it in place. Once the front panel was on the floor, I simply lifted the old part out and placed the new part in. I closed the front, replacing the part with wires back into the bracket, locked the top down tight, replaced the screws, and I was finished.

I then opened the top of the dryer to be able to lay the front on the floor. There were wires connected to the front, however, so I had to remove the part that the wires were connected to by slipping it out of the bracket that held it in place. Once the front panel was on the floor, I simply lifted the old part out and placed the new part in. I closed the front, replacing the part with wires back into the bracket, locked the top down tight, replaced the screws, and I was finished.

Parts Used:

-

Cathy from Dallastown, PA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Lint Duct tearing clothes and collecting large amounts of lint

After reading the comments of on-line customers, I realized the dryer opens like the hood of a car and then you pull the front of the dryer door off in order to get to the two screws holding the old lint duct housing unit. Putting the new part on was easier, but I would have appreciated a detailed picture along with the written instructions. Thank you for your quick delivery. Kathleen Yosso

Parts Used:

-

Kathleen from Belmont, CA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor froze up

First lift the top and remove 2 screws holding the front panel on, at each top corner. Release the door switch from its clip (or disconnect the wires). Remove the front panel by tilting out and then lifting it up off the bottom tabs. Remove the belt from the motor by releasing the tensioner. Then lift the drum out. Remove the front blower cover, then remove the tensioner by first removing the spring, then pull the tensioner out toward the back. Remove the strap on the back of the motor near the pulley. It takes a little effort to get the strap off. Remove the 3 bolts holding the blower case (with the motor still attached. Remove the motor wires, then lift the motor and blower case out. Next remove the clip holding the blower fan on and remove the fan. It may be stubborn so be patient and slowly work it off. Remove the next clip behind the fan. Then remove the motor from the blower case by turning it counter clockwise (as viewed from the motor side). Installation is the reverse.

Parts Used:

-

Randy from Loganville, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Wrench (Adjustable)

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My lint filter had developed holes.

It was supper easy. I was able to order the correct part from the detailed description you provided. I just opened it and slid it into the slot for a perfect fit.

I wish I had done it sooner. My filter had holes in it for some time.

I wish I had done it sooner. My filter had holes in it for some time.

Parts Used:

-

Barbara from Oak Park, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

squealing/squeaking noise

It took me a bit to figure out how to get the outer case to come apart (there are two spring-loaded latches under the front edge of the lid, had to insert a putty knife at just the right spot then lift up the lid). Once it was taken apart, I manually spun the drum to see where the noise was coming from and it was obviously coming from one of the two wheels that support the rear of the drum. Took out the drum after sliding the belt off and replacing the wheels was a piece of cake. They are held on by E-clip style retaining rings, which I destroyed when removing them with a pair of pliers. Luckily the new set comes with new retaining rings, along with the required washers and spacers. I also replaced the metal pins that the wheels spin on, since mine were showing wear and I wanted to make sure it wasn't going to keep squealing after I was done! All in all it was pretty easy! Before you take the belt off, make sure you take note of how the belt winds around the tension wheel so that you put it back on correctly! My girlfriend was VERY impressed that I was able to fix her dryer for about 1/10 of what it would have cost to get a new one!

Parts Used:

-

Damon from Chicago, IL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

6 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Originally Noisey While Running

Unplugged electric, turned off gas valve. Opened top using a putty knife, laid it gently back against the wall for support. Removed 2 screws holding front on-leaned front out about 3-4 inches- while holding front with my knees I disconnected door switch wires.-then removed front panel. Followed instructions on maintenance sheet glued on underside of dryer top (Lucky it was there). Took tension off drive belt. Removed belt and drum following instructions on lid sheet. Removed old slides (worn out) Installed new pads & slides. Vacuumed out all lint/dust/dirt I could reach, Cheked rear drum rollers. Reinstalled everything that I had removed. It took extra time to do everything because dryer was in tight space, little working space. Turned gas on, plugged in electric cord. Worked great now.

Parts Used:

-

Gary from Park Hills, MO

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

7 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!