41799463820 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

the belt was all worn out , it make a lot of noise

i took out the two back screws lift the top.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

took the two bottom front screws , lifted andtook off the front panel.took off the old belt an intall the new one in a circular motion put the panel and top back on and done.

Parts Used:

-

CARLOS from BEALETON, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

26 of 38 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum would squeak and squeal until warmed up, but progressively got worse as the days drug on.

First pry up on the front edge of the top panel of the dryer which is held in place by snap in clips. Pivot the top open and support against wall or other taking care not to pull on wiring harness. Next remove the 2 screws that hold the front panel in place. These are located on the inside of the front panel. The front then snaps loose also. Remove the plastic drum stop located at the top edge of the front of the dryer. Next I removed the 3 drum screws located inside at the back center of the dryer. Next you can you need to remove the belt the motor located at the rear vent panel on the back. Slide the now loose drum out exposing the rear bearing. With a 5/16 end wrench, loosen the 2 screws on either side of the bearing retainer. Assemble the new bearing bracket to match the old one. Apply a liberal amount of supplied lubricant to the pivot ball and plastic retainer. At this point it was helpful to have someone at the rear of the dryer hold the new retainer bracket against the back of the dryer while I tightened the new bearing assembly in. Assemble dryer in reverse.

Parts Used:

-

Chad from Glyndon, MN

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Screw drivers, Wrench set

19 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Leaking washing machine.

Removing the piece above the tub gasket was very difficult. A lot of hammer and chisel work.

15 year old machine. A lot of calcium build up around the shaft. I used a screw driver as a chisel and a hammer. Carefully removed the metal around the shaft to get to the tub seal.

Once I got to the tub seal it was easy. Remove the old rubber stops. There were a few pieces. Then sealed it back up with the oil that came with the PartSelect Kit and put it back together. Works great now. No more LEAKS! Yippy.

15 year old machine. A lot of calcium build up around the shaft. I used a screw driver as a chisel and a hammer. Carefully removed the metal around the shaft to get to the tub seal.

Once I got to the tub seal it was easy. Remove the old rubber stops. There were a few pieces. Then sealed it back up with the oil that came with the PartSelect Kit and put it back together. Works great now. No more LEAKS! Yippy.

Parts Used:

-

Ron from Williamsburg, MI

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

24 of 37 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Final Spin Burning Smell

Removed 2 screws at bottom of the front panel - removed front panel by sliding the panel down about 1/2 inch and then away from the appliance- v belt is removed by pushing the tensioner pulley to remove tension from the belt and turning the pulley untill the belt is removed instalation is a simple reverse of the process. I did't have a repair manual so every step was trial and error untill I was able to complete the repair.

Parts Used:

-

NELSON from MAYWOOD, IL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench (Adjustable)

17 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin

Received lid lock within 24 hours, fixed washer within 10 minutes...up and running. Thanks.

Parts Used:

-

KELLEY from KANSAS CITY, MO

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

22 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Burning smell, lots of hi-pitched squeaking

I got online and figured out exactly how to take off the front of the washer and then how to replace the belt. It was so easy. The part itself arrived much sooner than predicted. It fit perfectly and my washing machine is now running smoothly and quietly.

Parts Used:

-

Heather from Stephenville, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

17 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

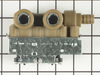

water continued to flow into machine during spin cycle

After moving machine to an area that allowed easy access to the unit, disconnected the water supply hoses from the inlet valve.

Removed the two screws that keep the back in place, removed the clips that keep the top in place, moved the top over far enough to get the valve out. Removed the screw that keeps the inlet valve in place, disconnected the power supply to the valve, Pulled valve out in order to remove the water outlet hose. Repalced with new vale, and reversed order to install. Works just fine now.

Removed the two screws that keep the back in place, removed the clips that keep the top in place, moved the top over far enough to get the valve out. Removed the screw that keeps the inlet valve in place, disconnected the power supply to the valve, Pulled valve out in order to remove the water outlet hose. Repalced with new vale, and reversed order to install. Works just fine now.

Parts Used:

-

Howard from Lcolnton, GA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

No Cold Water

Checked problem on-line and discovered it was the water inlet valve. Matched the part on part select. Com. Finding the part was very easy. Part select had a grid behind the picture to help determine the size and pictures from all sides. Removing the old part, matching it, and replacement took a total of 30 minutes. I now have clean clothes.

Parts Used:

-

Mark from Pittsburgh, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

16 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer machine would fill up with water and not spin and drain

Happened to slam the lid by mistake and the washer started spinning. Recognized the lid lock was working haphazzardly. Also, there was a burning type odor coming from the switch. So I lifted the lid top and disconnected the switch from the lid by unscrewing 2 screws and 4 wires. When I received the new switch, I reinstalled it with 2 screws and reconnected the 4 wires.

Parts Used:

-

MARC from MANALAPAN, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

18 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old Dryer drum veins degraded and broke down.

I opened the top of the dryer to gain access to the outside of the drum. Then I removed the screws holding the old drum veins in using the electric drill with the nut driver attachment. Then I positioned the new veins in place on the inside of the drum and replaced the screws from the outside of the drum to hold the veins in place. Then I replaced the top and was ready to go.

This is the third repair that I have done using parts from parts select. the other two repairs involved replacing electrical parts. Specifically thermostatic controls or swicthes. I am very happy with the parts and the diagrams provided on your web site without wich I would have had to replace my dryer a long time ago.

This is the third repair that I have done using parts from parts select. the other two repairs involved replacing electrical parts. Specifically thermostatic controls or swicthes. I am very happy with the parts and the diagrams provided on your web site without wich I would have had to replace my dryer a long time ago.

Parts Used:

-

Alfred from Loveland, CO

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver

15 of 18 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer Drum Squealing Loudly!

This unit is a stackable washer&dryer,so first pull unit away from wall atleast 4 foot. Unplug power cord,then take10 dagree front panel off then the control panel off and unplug the 5 connetors if your unit has that many,then lay panel asside. Take dryer door off,makes it easier when putting it all back together. Now take front panel off and the dryer lent tube,now just take the 3 center phillips head screws out and slide drum out. Pull upward on what they call the shaft which held drum on. Now these are the parts you should order. Belt,grounding ball clip,grounding ball,drum support bearing,bearing bracket,and most important part is the shaft. The shaft is ur insurance for the whole job. Use a good grease like white lithium grease and coat the shaft end and the drum support bearing. The grease will cut down on friction for a while,and re assemble the way you took apart. Reminder grounding ball goes behind drum support bearing not in front. Good luck and please vaccum.

Parts Used:

-

john from waynesboro, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

13 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Small water leak around front of machine and clothes would not spin dry.

Removed the 2 screws that hold the front panel on and slid the panel down to remove it, after first lifting the top panel and supporting it in the upright position out of the way. popped the two clips that hold the pump on, and used the pliers to remove the hose clamps on the pump. the pump was rusted to the motor shaft, so I had to use some force to pry it off of the motor. then i had to use some sandpaper to clean the rust off of the motor shaft. slid the new pump on and secured the hoses and hold down clips. then pushed the belt tensioner in and replaced the belt. the machine is like new again.

Parts Used:

-

Chanc from Gibson City, IL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

15 of 21 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

washer belt broke

-

Carl from Boxford, MA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

11 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wretched screeching noise

Make sure you order a new belt and a new drum glide with the rear drum bearing assembly. If your bearing is worn out, so are the belt and drum glide!

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

1) Use a flat screw driver or putty knife to release the blind clips that hold the front side of the top of the dryer cabinet down

2) Swing dryer top up and remove two screws that hold the face of the cabinet.

3) Unplug the wiring harness and remove the cabinet face.

4) Remove the 3 screws that hold the drum to the bearing assembly (accessed from inside the drum. This makes it easier to remove the drum as the bearing assembly can be difficult to remove before you see how it snaps together

5) Reach under the drum and take the belt off the motor pulley, then remove the drum

6) Remove the old bearing assembly from the socket (slide up then out)

7) Remove the two screws that hold the bearing socket to the dryer

8) Fasten the new socket to the dryer (you'll need help doing this unless you have REALLY long arms because you have to reach inside the driver and the back of the dryer at the same time)

9) Grease the socket with the supplied high temp grease

10) Bolt the new bearing assembly to the drum and put the new belt around the drum

11) Put the drum back in and snap the bearing socket in and down

12) Guide the new belt around the motor pulley & tensioner

13) Glue the new drum glide / felt piece to the front cabinet

14) Put the cabinet back together

Parts Used:

-

Paul from Broadalbin, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

9 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

leaking water inlet valve

removed the two 'lock down flanges' from the back of the machine, lifted the top from the front and slid it forward to access the valve. Removed the two electrical connections then the compression ring from the hose on the output side. Removed two screws holding the valve in place, then reversed the process.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

I wish this valve was made of metal rather than plastic. I had to replace it because the threads were stripped. Here's the heads up. Make sure the fittings on your supply hoses are 'clean' or you'll mess up the plastic threads and not get a good seal.

Parts Used:

-

Steven from Oklahoma City, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

9 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!