40400119 General Electric Dishwasher - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Dishwasher would not Drain

Since the pump and the motor was a single unit, I removed the assembly by disconnecting the electrical plugs and drainage connections. This was a very simple installation. I reversed the above steps, reinstalled the dishwasher and all worked out well.

Parts Used:

-

Alfred from Fernandina Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

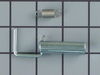

attaching overflow micro switch to new plate

Once i had the dishwasher removed everything went as the instructions indicated except for the overflow switch.I removed the switch from the old bracket which is not required,just install the switch assy. to the new bracket and proceed as instructed. the total repair shouldn't take more than 1 hour if you don't make the mistake i made.I AM VERY SATISFIED WITH PRODUCT.

I HAD NEXT DAY DELIVERY AT REGULAR POSTAGE CHARGE.

I HAD NEXT DAY DELIVERY AT REGULAR POSTAGE CHARGE.

Parts Used:

-

GEORGE from CHAMBERSBURG, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

10 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The old pump for this 21 year old dishwasher was leaking. Reviewing the cost of a new dishwasher at the big box stores convinced me replacing the part would be much less money.

I had hoped to be able to do the entire replacement at the floor level through the front panel without moving the dishwasher out of the cabinet. That turned out to be impossible because two of the machine screws holding in the old pump rusted and would not budge.

I did however manage to do the replacement by moving the dishwasher only 16 to 18" out of the cabinet so that I could work on more than one side. A word of advice: Once the pump is disconnected get it out of the house as soon as possible. It will continue to leak on your floor otherwise. No point in getting your pants, shirt and tools all wet.

The best part of this replacement came when I buttoned the whole thing back-up and ran it. This new pump was significantly less noisy than the old one making it possible to stay in the kitchen and actually have a conversation with someone. (My dog no longer leaves either.)

Would I do it again....you bet!

I did however manage to do the replacement by moving the dishwasher only 16 to 18" out of the cabinet so that I could work on more than one side. A word of advice: Once the pump is disconnected get it out of the house as soon as possible. It will continue to leak on your floor otherwise. No point in getting your pants, shirt and tools all wet.

The best part of this replacement came when I buttoned the whole thing back-up and ran it. This new pump was significantly less noisy than the old one making it possible to stay in the kitchen and actually have a conversation with someone. (My dog no longer leaves either.)

Would I do it again....you bet!

Parts Used:

-

John from Deep River, CT

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor seized on 1990 GE dishwasher

The motor seized up on my 1990 GE Dishwasher

Repair would cost 360. Replacement about 600

I ordered the motor and pump from PartSelect for 137..44

Remover the under counter washer (it‘s very light) and removed the water and drain line and disconnected the power. Turned the washer on it’s top to access the motor and pump and removed the electrical plug in lines, and the clamps holding the pump on to the connections. Replaced it with the new motor and pump, reconnected the electrical plug ins, added an adapter hose part, tightened the original clamps then reconnected the water, drain and electrical connections and reinstalled the washer. All in about an hour, The only glitch was the grounding screw for the ground wire on the motor. The screw was too long to tighten. Substituted the original shorter ground screw from the old motor, and that worked fine. Only used 4 parts from the large assortment of parts supplied.

Immediately ran the washer through a cycle, all worked perfectly.

Repair would cost 360. Replacement about 600

I ordered the motor and pump from PartSelect for 137..44

Remover the under counter washer (it‘s very light) and removed the water and drain line and disconnected the power. Turned the washer on it’s top to access the motor and pump and removed the electrical plug in lines, and the clamps holding the pump on to the connections. Replaced it with the new motor and pump, reconnected the electrical plug ins, added an adapter hose part, tightened the original clamps then reconnected the water, drain and electrical connections and reinstalled the washer. All in about an hour, The only glitch was the grounding screw for the ground wire on the motor. The screw was too long to tighten. Substituted the original shorter ground screw from the old motor, and that worked fine. Only used 4 parts from the large assortment of parts supplied.

Immediately ran the washer through a cycle, all worked perfectly.

Parts Used:

-

DAVID from UNION MILLS, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Old roller wheels were starting to stick due to cracking

1. I pulled off the plastic end caps to the top rack that allows the roller wheels to be pulled out of the aluminum rails. You need to push in the raised edge of the plastic caps so they clear the rail slot in order to remove them. This takes a little bit of finger pressure or you can use a flat-edge screw driver to pop them out.

2. Once this procedure is completed, you simply remove the rack and rollers from both rails and remove the old roller wheels and replace them with the new ones.

3. I used a phillips-head screw driver to tighten up the rail wheels before re-installing the top rack into the rails and then re-inserted the end caps. Pliers are handy to help get the end caps back into the rail slots.

4. I finally used a silcon spray on all of the rolling parts of the top tray assembly for lubrication.

2. Once this procedure is completed, you simply remove the rack and rollers from both rails and remove the old roller wheels and replace them with the new ones.

3. I used a phillips-head screw driver to tighten up the rail wheels before re-installing the top rack into the rails and then re-inserted the end caps. Pliers are handy to help get the end caps back into the rail slots.

4. I finally used a silcon spray on all of the rolling parts of the top tray assembly for lubrication.

Parts Used:

-

Jeffrey from Springfield, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

8 of 9 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Very, very easy. Took about 5 minutes. The end cap was on and working. And the repair company would charge $65 just to come out and look at it. It costs $9.00 to fix it. I am moving on to the refrigerator next. Very satisfied. Shipping is well worth the money. Ray D, Ansonia, CT

Old cap was already off and had string on it. Cut the string. Placed end cap over. Used needle nose pliers to open metal rail a little and put in new cap. Locked right in. That was easy. Thanks again.

Parts Used:

-

Raymond from ansonia, CT

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

8 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water leak at lower right corner of door.

Replaced door seal, right and left corner seals. Piece of cake. A five minute job.

Thanks

Thanks

Parts Used:

-

Patrick from Canyon Country, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

9 of 13 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

2 rollers and end caps were broken were broken

Pulled the basket out the appliance and took what was left of the roller off and replaced them and slid the basket back onto the slide channel into the appliance. Then snapped the end caps on. Almost too simple. Less money than it costs to have the service man ring your door bell.

Parts Used:

-

Robert from Old Lyme, CT

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water wouldn't drain.

After disconnecting the supply and drain hoses I unscrewed the security screws and slid the unit out of it's space under the counter. I tipped the machine about 30-45 degrees to one side and examined the underside. I noticed a solenoid that appeared to control a valve leading to the drain tube. I cycled the washer through a wash cycle and noticed that the solenoid never activated. I removed the solenoid and found it filled with debris. I cleaned it out and reinstalled it, but it still did not function. I ordered the part from PartSelect.com because they had the clearest description of the part I needed. Delivery was quick and installation took only a few minutes. After hooking everything back up and sliding the machine back in place, it works like new.

Parts Used:

-

Lawrence from Silverdale, WA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Eyelet Assembly Broke

Took off the lower faceplates. Removed the old eyelet assemblies (one broken, one not) and replaced both with new ones. Very easy to repair.

Parts Used:

-

mark from Fleming Island, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

6 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Soap dispenser door wouldn't close

Replaced all ordered parts.

Parts Used:

-

Clint from Quakertown, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

21 of 52 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher wouldn't drain

Once the new motor and pump kit arrived. I removed the dishwasher, turned it upside down and replaced the motor and pump with the new one per the directions. Difficulty came in feeding the electrical wire/plug back through the cabinets. Once done, turned on the dishwasher, filled the tub, then manually moved the dial to drian. The water still would not drain from the tub. I searched further for the problem. Here it is; Found the air gap tube was plugged with food. Once I removed, cleaned and reinstalled the air gap, the tub drained fast and everything works great. So, I hope you folks put this up in your troubleshooting section for others to check before buying a pump and motor kit. If you had, I would have been able to check out the air gap, clean it out first before spending $140.00 for a pump and motor kit I didn't need. Anyway, lessons learned..Jeff

Parts Used:

-

Jeffery from Sparks, NV

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dishwasher wouldn’t start

Took the screws out of the back of the doorl located the switch and replaced it put screws back in and it was fixed

Parts Used:

-

Stephen from MARENGO, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

7 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My dishwasher would not start.

I unscrewed the inside of the dishwasher door and clearly saw the old interlock switch. This dishwasher has two, but it was obvious that one switch worked and one didn't (one switched was permanently pressed in). I removed the old interlock switch. It was tricky to pull out and I felt like I was going to break it but after watching youtube videos, I was pretty sure you just have to pull hard. I easily put the new switch in, reattached the dishwasher door, and it works perfectly!

Parts Used:

-

Rebekah from NEW ORLEANS, LA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken Roller

I watched the video and did exactly what he did. I am a novice when it comes to repairs. I learn as I go. This repair went flawlessly. Ordering was quick and easy. The part arrived quickly. The repair took less time than expected. The part was what I needed and nothing else broke or went wrong when repairing the original problem. It was a 100% success.

Parts Used:

-

Michelle from Richardson, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!