12302 ((1988)) Kenmore Range - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Exhaust Fan Switch broke so you couldn't turn the fan on.

I removed the screws that hold the escutcheon assembly in place and lifted it from the range top. I slipped the wire connectors from the old switch and removed the push nuts. Removing the push nuts was the most difficult part. I wedged a small screwdriver under them and made enough space to cut them off with wire cutters (DON'T CUT THE POLES THE PUSH NUTS ARE ATTACHED TO!). There may be an easier way to remove them, but I'm a rookie and don't know what the easier way would be.

I attached the wires back to the same poles on the new switch as they were positioned on the old switch and pushed on the push nuts that came with the new switch to hold it in place. There isn't much room to work with so I used a small socket from a socket wrench set to hold the new push nuts in place while I pushed them on. The push nuts I received with the new switch were really too small. I forced one on, but broke the other one. I bought another slightly larger one at my local hardware store and it worked great.

I reattached the escutcheon assembly and was back in business. Overall, it took me about 30 minutes.

I attached the wires back to the same poles on the new switch as they were positioned on the old switch and pushed on the push nuts that came with the new switch to hold it in place. There isn't much room to work with so I used a small socket from a socket wrench set to hold the new push nuts in place while I pushed them on. The push nuts I received with the new switch were really too small. I forced one on, but broke the other one. I bought another slightly larger one at my local hardware store and it worked great.

I reattached the escutcheon assembly and was back in business. Overall, it took me about 30 minutes.

Parts Used:

-

James from Norcross, GA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers

10 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Didn't like the appearance of a cheap-looking dryer vent on an exposed area of my new house.

I enlarged the vent access hole from four (4) inches to five (5) inches to accomodate a larger pipe. I then purchased locally a 5" to 4" transition and installed it in the enlarged opening, and sealed the space with expanding foam for a bug-proof air-tight fit. On the inside of the house I attached a short length of 4" pipe to attach the dryer vent pipe. On the outside, in the place of the aluminum vent cap, I installed the 5" Jenn-Aire vent cover purchased from PartSelect.com. The new vent is large enough to completely cover the chiseled out masonry area, and the 5" outlet reduces air noise from the dryer, but best of all the new vent provides the high quality look I needed to match the brick of my new home.

Parts Used:

-

Robert from Jacksonville, AL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

7 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

old cracked

-

JOHN from GAINESVILLE, GA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

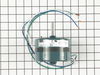

Downdraft Motor Bearings Shot

I first had to purchase the replacement motor which was quoted from a high of $236 to a low at graingers of$100. 00. The counterman at graingers removed the blower fan from the motor for me with a special long handled allen key. I then degreased and cleaned the blower fan. I had to cut off the screws on the motor and replace the 3 motor isolators and the urethane foam around the motor. I had to thread the 3 wires from the new motor through the bx cable from the old motor and reattach the fan to the motor. Anyone wanting more detailed informatioin may contact me at:mablume@optonline. Net

Parts Used:

-

MICHAEL from LAKE GROVE, NY

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Broken fan switch

Turn off the power to the appliance. Remove the two screws from the control panel. Turn the panel over leaving all wires attached. Others have complained about the difficulty in removing the old push nuts and installing the new ones – this way worked quickly and easily for me: to get the old nuts off – take an awl and wedge it between the flat part of the push nut and the plastic mounting tab of the switch body. Pull the awl upwards until it is parallel with the mounting post. The push nuts will break, use needle nose pliers to remove the broken push nuts. Pull the old switch out noting the orientation. Place the new switch in place over the mounting posts. The new push nuts are not too small, it just takes some force to get them on (a good thing, it keeps the switch in place). Easy way to get the new nuts on: take a small nut driver that is the same diameter as the new push nuts on a straight handle, and use it to force the new push nuts onto the posts. Move the wires from the old switch to the new one. Turn the panel back over, replace the two screws, restore power to the appliance. It is a 10 minute job with the right tools.

Parts Used:

-

Eric from Johnston, IA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers, Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Igniter stuck in on position.

removed 2 screws to access the ignitor. Discinnected the wires from the old ignitor and slid the old ignitor off. Installed the new ignitor and attached wires.

Parts Used:

-

terry from joplin, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

my old knobs melted when someone placed a hot cookie sheet on them

This wasn't a repair; it was a desperately needed replacement. I simply popped off my old knobs and put the new ones on in less than 1 minute. The new knobs took years off my beloved gas Jenn-Air stove.

The knobs arrived within two days of placing my order. Outstanding customer service. I will order from this company again and again.

The knobs arrived within two days of placing my order. Outstanding customer service. I will order from this company again and again.

Parts Used:

-

Theresa from Davis, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 6 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

drain jar lids rusted and broken of their mounts

The lids are fastened to the underside of the unit by rivets....3 to each lid.

I used a cordless drill and small drill bit to drill through the rivets to remove the old lids and remains of the rivets.

The new lids are easily fastened back using a rivet gun ( about $20 in Lowes) using small 1/8th aluminum rivets.

No real problems.

1 thing to note is that the drill bit will pass through the old rivet by about 1/4 inch before it comes up against the upper level of the BBQ floor so do not drill any deeper.The aluminum rivets are easy to drill through and you will easily feel when the rivet is drilled through.

I used a cordless drill and small drill bit to drill through the rivets to remove the old lids and remains of the rivets.

The new lids are easily fastened back using a rivet gun ( about $20 in Lowes) using small 1/8th aluminum rivets.

No real problems.

1 thing to note is that the drill bit will pass through the old rivet by about 1/4 inch before it comes up against the upper level of the BBQ floor so do not drill any deeper.The aluminum rivets are easy to drill through and you will easily feel when the rivet is drilled through.

Parts Used:

-

ronald from ESTERO, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor bearing failure after 34 years.

Important: Down load the helpful assembly diagram for the fan motor and study it for a few minutes. It's very straight forward. Also a good idea is to remove the bottom panel which comes off easy before starting.

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work bench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

Parts Used:

-

Wade from CARMINE, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Reusable Grease filter was old and worn out.

The Model number could no longer be read clearly on the stove electric grill with a down draft vent system, so all I had was the size and looks of the old grease/air filter. I was very happy to come across Parts Select by way of an amazon.com search. Their web site's design and the parts pictures with detailed descriptions made it easy to find exactly what I needed. The grease filter fit perfectly in no time. I have successfully used my cooking grill again.

Parts Used:

-

Gloria from Galveston, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Original switch was cracked, then shorted and melted.

The repair was super-easy, the hardest part was removing the old screws and switch. I slid a putty knife under the old switch and used that to pry up while I unscrewed the nuts. The new switch was a very snug fit on the two studs, which was nice, but the nuts included with the new switch were too small as-is. I could have driven a punch through to increase the diameter, but I kept my old nuts and re-used them instead.

Parts Used:

-

Michael from Bremerton, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

One burner would not ignite (no spark)

Since the other three burners sparked, I traced the problem to the switch on the valve shaft. To replace, (after unplugging the power cord) I pulled off the knobs, removed the two screws on the valve cover (inside the downdraft vent) and pulled the switch up the shaft to remove. I transferred the spade terminals to the replacement switch, oriented and installed.

Parts Used:

-

Mark from Clarksburg, NJ

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 4 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Wall vent cap & damper were broken.

Attached spring to damper, placed on existing 5" duct and secured. Used screwdriver to attach vent cover to damper.

Parts Used:

-

Jim from Sulphur, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

5 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

high blower vibration

blower wheel was caked with dried grease clumps; replaced blower wheel, urethan foam and 3 motor isolators; blower/fan no longer vibrating cooktop.

Parts Used:

-

Lawrence from Chandler, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

9 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Fan switch was broke; fan would start on it's own, but not when I needed it. Grease filter was in pieces.

Be sure to turn power off; then follow the instructions on the older posts.

Parts Used:

-

Bertram from Blacksburg, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

4 of 5 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!