11020022014 Kenmore Washer - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Violent shacking in spin mode.

-

Terry from Homosassa, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Wrench (Adjustable)

181 of 219 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top of agitator didn't agitate. It was slipping.

Pried off the agitator cap. Removed the bolt. Removed the agitator. In the process of separating the agitator from the base, a plastic tab broke off which concerned me. BUT, in the directions with the part it explains that the 2 tabs are for factory assembly and to break both of them off. Broke off the second tab and reassembled. My 18 year old Kenmore is back in action.

Parts Used:

-

Steve from Naperville, IL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

110 of 122 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noise on bottom of Washer louder as time went on. 1 1/2 years

Well, first investigated and found loose nut on drive clutch. First take off the two screws with nut drive then cover off using a screwdriver blade to snap off the cover. Then socket ratchet to take off the nut on drive clutch. take off belt by slowly rotating the drive gear. two screws that hold the electronics to the upper drive clutch and put aside, so you can snap off the cover for drive clutch on upper part with screwdriver and off the parts come and install whole unit back as took it apart. Line up the new upper clutch so that is position as was before. (Using parts diagram helps a lot as www. partsselect.com has for you or Maytag.com.) Then put the electronic part board back on and the gear and nut. Make sure it is tight by several attempts to make sure it's snugged up good and then slowly roll belt back on the pulley and motor drive. Put your cover guard back on with two screws and done.

Parts Used:

-

Jerry from WALLA WALLA, WA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers, Socket set

83 of 112 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Scratches in Surface

This product comes in a bottle with a brush like Liquid Paper. It goes on incredibly easy. A second coat might be needed. I wanted to prevent rust from setting in so I covered the scratches and dings. The paint is a little brighter since my washer is 10 years old but it still looks great.

Parts Used:

-

Michelle from Richardson, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

64 of 125 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noise, grinding sounds. Wash tub stopped turning but motor and cycles kept functioning. Process of elimination, must be the clutch assembly.

Easy, just followed the repair video. Recommend also ordering the drive belt. Bought one locally during my repair.

Parts Used:

-

David from BLOOMINGTON, IN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

35 of 42 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was damaged from apparent overload

With the PartSelect website instructions, I was able to take the agitator apart easily, diagnose the problem and select the replacement parts to effect the repair. The only issue I faced was the shipment damage to the repair parts, but the service department with PartSelect responded quickly and fairly to correct the damage. I have never seen a website like PartSelect.com that trains you in making the repairs, provides you with the required parts and then stands by to resolve any issues you face; I was awed by how confident that it made me feel throughout the process.

Parts Used:

-

Roy from Salisbury, NC

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

40 of 66 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Over shaking and knocking on the side

Went on u tube saw different video to How disassemble the top to have access to the rod. Changing one by one those rod I was in need of my wife to hold the cover while I was changing the rod.... order for suspension rod kit. Reassemble the top by sliding the cover and to snap. Screw back the panel. And it solve the problem. My wife was really happy so me. It can be done by anybody but first go on the internet to get a idea.

Parts Used:

-

Alain.m from HARLINGEN, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Socket set

24 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top half of the agitator was not turning.

I just took the cap of the agitator off and the 3/8" nut was right there. I took it off with a socket, removed the top agitator, slid the assembled kit in , replaced the agitator and cap...that was it !!. These parts priced thrrough Sears were $77.00 plus S&H. Your price for the entire kit- less than $12.00 !! If you don't think that you can do this yourself, have your 7 year old child do it. Took me about 5 minutes. Great price and fast shipping. Thanks

Parts Used:

-

Dennis from Avon, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

24 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Smelled a burning odor occasionally

First, I checked the belt before ordering and then decided to order the belt, capacitor, and clutch assembly (if I needed to replace). I replaced the belt noticing the older belt came right off and new one was tighter going on. I replaced the capacitor since I had it handy and it can be known to cause this smell also. After setting washer back up and started a cycle I noticed the spin cycle would not start properly so I thought maybe the capacitor (new one) was faulty or just not the exact match even though it was said to be. I replaced my older capacitor back on and again ran cycle and it ran great. Thus I decided to send the parts which were not used. I would recommend this site as I have used them in the past before on other items. They ship fast and have a great return policy if parts not used.

Parts Used:

-

Paul from E NORTHPORT, NY

-

Difficulty Level:Very Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Socket set, Wrench (Adjustable)

16 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water inlet nozzle was stripped and leak

Remove the front panel and back panel unplug the part unscrewed the part and replace it with the new one

Parts Used:

-

Armand from WESTPORT, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

23 of 48 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Darn thing hadn't "Agitated" for about 10 years!

After removing the bolt (7/16" head), and using a pair of pliers to remove the 3-4 in deep "cup", it was immediately obvious how to assemble the new cup and pawls (ratchets).

Orienting the black "bearing" was not so obvious, but on closer inspection of the illustration, it became clear. The four "ears" of the bearing go closest to the pawls. The little tabs that are co-planar to the ears fit into the four grooves of the new cup.

And here's the trick (besides making REALLY, REALLY SURE how the pawls orient)--Soak the black bearing piece in hot water to soften it up, and let it slide over the cup better. If you don't, you risk breaking it. If you do, it slides over and "clicjs" into place, with the ears resting right against the bottom lip of the cup, capturing the pawls.

Installation back into the washer is obvious.

The thing works like a charm! It hasn't worked this well for a decade!

Orienting the black "bearing" was not so obvious, but on closer inspection of the illustration, it became clear. The four "ears" of the bearing go closest to the pawls. The little tabs that are co-planar to the ears fit into the four grooves of the new cup.

And here's the trick (besides making REALLY, REALLY SURE how the pawls orient)--Soak the black bearing piece in hot water to soften it up, and let it slide over the cup better. If you don't, you risk breaking it. If you do, it slides over and "clicjs" into place, with the ears resting right against the bottom lip of the cup, capturing the pawls.

Installation back into the washer is obvious.

The thing works like a charm! It hasn't worked this well for a decade!

Parts Used:

-

Stephen from Cornwall, NY

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

10 of 12 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top half of agitator wasn't moving

First, I wrestled off the top cap of the agitator. Then, I unscrewed the bolt and took out the cam. I noticed that the agitator dogs were worn smooth. I replaced them, put it all back together and VOILA! I bought the whole agitator kit, not knowing what I was going to find, because I wasn't a Magtag repair woman. It ended up that the cam that came in the kit was too big for my washer anyway. Luckily, all I needed was 4 plastic dogs. The price of the whole kit was so inexpensive anyway, it was no big deal. Especially because, I was looking to buy a new washer or a big repair bill. This website is great! Thank you.

Parts Used:

-

Debra from Orange, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Socket set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

wash machine walked

-

Elzoria from FROSTPROOF, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

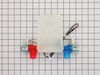

Hot water valve would barely open - take 35 mins to fill washer

Pull the washer out from wall

Unplug the Washer

Close the supply line valves

Unscrew the supply lines, use bucket to catch line water

Remove 1 cover plate for elec lines (1 screw)

Remove 2 screws on edge of back plate for control panel

Slide long blade under front of control panel corners, pop the lock clips

Lay control panel forward - controls down

Compare new and old part - looks the same, wires, etc

Remove center screw on back plate cover to remove it

Unplug the elec wires connecting the valves and the control panel

Remove 2 screws holding the water valve outlet

swap out the old values for new valves

Reverse the process - step backwards and reassemble

Took me 36 minutes.

Tested the washer for Hot fill and later cold - both work

Unplug the Washer

Close the supply line valves

Unscrew the supply lines, use bucket to catch line water

Remove 1 cover plate for elec lines (1 screw)

Remove 2 screws on edge of back plate for control panel

Slide long blade under front of control panel corners, pop the lock clips

Lay control panel forward - controls down

Compare new and old part - looks the same, wires, etc

Remove center screw on back plate cover to remove it

Unplug the elec wires connecting the valves and the control panel

Remove 2 screws holding the water valve outlet

swap out the old values for new valves

Reverse the process - step backwards and reassemble

Took me 36 minutes.

Tested the washer for Hot fill and later cold - both work

Parts Used:

-

Kevin from ARLINGTON, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

9 of 10 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top section of the agitator would not work properly

Removed the top cap, unbolted the agitator, lifted off the top section, removed old "dogs" and replaced new "dogs", reinstalled agitator and tested.

Parts Used:

-

James from Crownsville, MD

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

12 of 20 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!