1101820296 Kenmore Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Water drips inside washing machine, suspected the inlet valve needs to be replaced

Before ordering part, took the old valve out to make sure it looks similar to the one described online by Partselect. After ordering online, put things back together since I expected delivery would take 5-7 days. That night the water stopped dripping and has been OK ever since. I suspected that there was some rust in the electrical connections. By disconnecting and reconnecting the terminal, the electrical connection is better and water stopped dripping. Still keep the new part just in case (which came overnight after I ordered it).

Parts Used:

-

PHU from Laguna Hills, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

52 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer wouldn't spin or agitate. Made louder-than-usual noise during those cycles.

1. Read many other repair stories for similar symptoms. PartSelect Forum was an excellent resource.

2. Posted my problem on PartSelect Forum and awaited reply. Read replies, and followed provided link to step-by-step guide for the procedure. PartSelect forum moderators were excellent advisors!

3. Performed the first half of the procedure to get to the diagnosed root cause. In some of the stories I had read, people had turned the washer on its back or tilted it up to get at the area from underneath. I am so glad I followed the conventional instructions, and left the washer standing and simply removed the cabinet. It was surprisingly easy. There's a reason why it was designed that way. I am also glad that I chose to remove the pump from the motor. While it is true that you don't *have* to remove the pump from the motor to get at the coupling...it hardly seems to make sense to remove the hoses instead. Removing the pump was incredibly easy, and by doing so, I never had to break any "wet" connections, and not one drop of water spilled over the course of the entire repair. (Even though I forgot to shut the water supply valves before I got started. Ooops! At least I remembered to unplug the power cord.)

4. But despite the open valves, the galoshes came into play not for their ability to repel water, but for their value as an electric insulator. I wrapped the galoshes around the handle of a long screwdriver when I discharged the motor's capacitor. :)

5. Ordered parts. Washed clothes in sink. Waited. Washed more clothes in sink. Waited some more. Washed more clothes in sink. Waited still more. Came very close to stopping payment to PartSelect because the very simple, commonly-requested part I ordered, which was supposedly in stock on the day I ordered it, didn't ship until the day it was supposed to arrive--even though I paid extra for expedited shipping. And I was never sent an e-mail to warn me that the parts were going to be delayed. And then to top it all off, rather than make up for some of the lost time caused by their own error, and ship it overnight, PartSelect chose to ship it 2nd day. All that good will generated by the excellent website completely evaporated by the failure to correctly complete the simple tasks that the business has needed to be good at since before computers were even invented. I will never use PartSelect again.

6. Prying the old coupler halves off of the motor and the washer took some effort, but was not overly difficult. I wound up removing the motor mounting plate in order to get better access to the half that was stuck on / needed to be attached to the drive train of the washing machine. Mounting plate was a breeze to remove and attach with a socket driver. I used one of those stubby flat-head screwdrivers to pry the old parts off. This was the one time where I thought it might have been easier to have the washing machine tilted up or on its back...but I muddled on through without even removing the bottom panel, and it wasn't too awkward. I used a large socket and a full-size hammer to not-so-gently tap the new parts into place. Putting all of the parts back together took a bit longer than it took to break them down, but it was easy. The instructions for putting the electronic control panel into test mode had been rolled up and taped to the cabinet inside the top panel. After I put the cabinet back on, I used those instructions to test all the cycles before fastening the top panel and testing the machine with an actual load. So far, so good...

2. Posted my problem on PartSelect Forum and awaited reply. Read replies, and followed provided link to step-by-step guide for the procedure. PartSelect forum moderators were excellent advisors!

3. Performed the first half of the procedure to get to the diagnosed root cause. In some of the stories I had read, people had turned the washer on its back or tilted it up to get at the area from underneath. I am so glad I followed the conventional instructions, and left the washer standing and simply removed the cabinet. It was surprisingly easy. There's a reason why it was designed that way. I am also glad that I chose to remove the pump from the motor. While it is true that you don't *have* to remove the pump from the motor to get at the coupling...it hardly seems to make sense to remove the hoses instead. Removing the pump was incredibly easy, and by doing so, I never had to break any "wet" connections, and not one drop of water spilled over the course of the entire repair. (Even though I forgot to shut the water supply valves before I got started. Ooops! At least I remembered to unplug the power cord.)

4. But despite the open valves, the galoshes came into play not for their ability to repel water, but for their value as an electric insulator. I wrapped the galoshes around the handle of a long screwdriver when I discharged the motor's capacitor. :)

5. Ordered parts. Washed clothes in sink. Waited. Washed more clothes in sink. Waited some more. Washed more clothes in sink. Waited still more. Came very close to stopping payment to PartSelect because the very simple, commonly-requested part I ordered, which was supposedly in stock on the day I ordered it, didn't ship until the day it was supposed to arrive--even though I paid extra for expedited shipping. And I was never sent an e-mail to warn me that the parts were going to be delayed. And then to top it all off, rather than make up for some of the lost time caused by their own error, and ship it overnight, PartSelect chose to ship it 2nd day. All that good will generated by the excellent website completely evaporated by the failure to correctly complete the simple tasks that the business has needed to be good at since before computers were even invented. I will never use PartSelect again.

6. Prying the old coupler halves off of the motor and the washer took some effort, but was not overly difficult. I wound up removing the motor mounting plate in order to get better access to the half that was stuck on / needed to be attached to the drive train of the washing machine. Mounting plate was a breeze to remove and attach with a socket driver. I used one of those stubby flat-head screwdrivers to pry the old parts off. This was the one time where I thought it might have been easier to have the washing machine tilted up or on its back...but I muddled on through without even removing the bottom panel, and it wasn't too awkward. I used a large socket and a full-size hammer to not-so-gently tap the new parts into place. Putting all of the parts back together took a bit longer than it took to break them down, but it was easy. The instructions for putting the electronic control panel into test mode had been rolled up and taped to the cabinet inside the top panel. After I put the cabinet back on, I used those instructions to test all the cycles before fastening the top panel and testing the machine with an actual load. So far, so good...

Parts Used:

-

Paul from Boonton, NJ

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

44 of 48 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

I smelled smoke and then it quit working

First unplug the electrical chord and disconnect the water supply after you have turned it off. Drain all water you can by putting the drain hose into a bucket or water container lower then the drain hose. Remove the two screws at base of the front panel. Then go to the back side of the machine remove the two screws at the top of the back panel, this allow you to remove the top switch panel. Remove the two screws at the bottom outside corners of the back panel and then you can lift the panel up and away from the base. I leaned the back against my dryer because I did not have a helper. Go to the front of the machine, lift the lid and grasp with one hand the machine's sheet metal lift and pull it off the base. There are two metal clips attaching the pump to the motor. The pump slides off and I did not have to remove the hoses. Unclip the electrical connectors from the motor and capacitor. The motor is mounted with two clips with a screw secure it in place. Unscrew and unclip and the motor should slide out. Be sure to inspect the direct drive coupler, the parts not too expensive. I had replaced mine just 4 months ago so I was good to go. Reverse the procedure and you should be in business.

Parts Used:

-

Paul from Lakewood, WA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

43 of 48 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Slow hot water, cold water was flowing normal.

First I disconnected power.

Next I turned off the hot and cold water supply hose bibs.

Once that's done, I pulled out the washing machine to get to the hose connections on the back of the machine, removed and drained the residual water in the hoses.

Note: Since the hoses were fairly new, I reused the supply hoses but replaced the rubber washers. However, if your hoses are older than a couple of years, it's cheap insurance to go ahead and replace since you're right there.

Next was to remove the two end caps of the control unit on top of the machine. This exposes the two screws that is then removed so that the control panel can rotate up and back.

Once the panel is open, I removed the single connector attached to the top of the machine. This leads to the lid open switch.

Followed by removing the two spring clips with the help of a flat blade screwdriver and pliers to keep the clips from flying off.

Once the clips are removed, the top/front shell of the washer is free to rotate foward. At this point, it can be removed or just laid to the side (forward).

This opens up the area to be serviced.

Disconnect the quick release wire connectors, taking note that the red connector is for the hot water control valve solenoid. disconnect the mix hose going to the tub from the valve by using pliers to disengage the hose clamp (catch the residual water with a sutable container). Then I removed the old valve assembly by removing the two screws holding the assembly to the back panel.

Follow the instructions enclosed with the part to preassemble and install the valve.

Reassemble by reversing the process. Check for leaks, test hot and cold water cycle and you're done.

It actually took me more time to gather my tools and pull out the washing machine than the actual replacement of the part!

Oh, by the way, I've purchased parts from PartSelect.com many times. Each and every time has been an outstanding experience. Quality parts, fast shipping and great prices! It's always been a pleasure!

Next I turned off the hot and cold water supply hose bibs.

Once that's done, I pulled out the washing machine to get to the hose connections on the back of the machine, removed and drained the residual water in the hoses.

Note: Since the hoses were fairly new, I reused the supply hoses but replaced the rubber washers. However, if your hoses are older than a couple of years, it's cheap insurance to go ahead and replace since you're right there.

Next was to remove the two end caps of the control unit on top of the machine. This exposes the two screws that is then removed so that the control panel can rotate up and back.

Once the panel is open, I removed the single connector attached to the top of the machine. This leads to the lid open switch.

Followed by removing the two spring clips with the help of a flat blade screwdriver and pliers to keep the clips from flying off.

Once the clips are removed, the top/front shell of the washer is free to rotate foward. At this point, it can be removed or just laid to the side (forward).

This opens up the area to be serviced.

Disconnect the quick release wire connectors, taking note that the red connector is for the hot water control valve solenoid. disconnect the mix hose going to the tub from the valve by using pliers to disengage the hose clamp (catch the residual water with a sutable container). Then I removed the old valve assembly by removing the two screws holding the assembly to the back panel.

Follow the instructions enclosed with the part to preassemble and install the valve.

Reassemble by reversing the process. Check for leaks, test hot and cold water cycle and you're done.

It actually took me more time to gather my tools and pull out the washing machine than the actual replacement of the part!

Oh, by the way, I've purchased parts from PartSelect.com many times. Each and every time has been an outstanding experience. Quality parts, fast shipping and great prices! It's always been a pleasure!

Parts Used:

-

David from San Diego, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers, Screw drivers

41 of 44 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer filled v e r y slowly

I'd noticed for a while that our 15-year-old Kenmore washer was filling slowly, but when it started to take 30 minutes to fill to the "medium" level, I knew something was really wrong. There was plenty of water pressure, so I replaced a hose that was loaded with minerals and cleaned the filter (also clogged with minerals). But that didn't help! So I ordered a new water inlet valve, and replaced that. There's nothing tricky about the repair -- the hardest part is opening and closing the washer, for which I found instructions online. (Even so, it's the most time-consuming part of the project.) The result is the washer now fills as fast as when it was new. Just for fun, I took apart the old valve and expected to find it encrusted with minerals, but it looked fine, so I'm not sure where the actual breakdown was. But since the part only cost $25 -- less than a service call, for sure -- I was very happy to use a half hour of my time and keep the machine going a while longer.

Parts Used:

-

Jonathan from Arlington, VA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers, Socket set

33 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Top door catch assembly had broken

It was so easy, that my wife did it the day we got the part before I got home from work. She wedged it out with a flat head screw driver and then pushed the new door catch assembly in with her thumb. Pretty simple, thanks for having parts like this available to the public!

Parts Used:

-

tony from prineville, OR

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

29 of 31 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

push to start switch was not working

Removed the old one and installed the new one! What impressed me the most was the amount of time for delivery, one day! Actually it came before 24 hrs!!! Very impressive! I would highly recommend this company!!!

Parts Used:

-

Grace from New Smyrna Beach, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Nutdriver, Pliers, Screw drivers

33 of 43 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer would fill/empty but would not agitate nor spin

Unplugged power cord and disconnected water lines; note which is hot/cold. Washer was then tipped on its front. Discharge hose was disconnected. Washer was then rolled over onto its back as this would put the pump on top for much easier removal.

Pried off two clips attaching pump on motor using a flathead screwdriver. The rear clip was done by touch. Unplugged wiring plug from motor. Using an adjustable wrench (socket set would have worked better), remove two screws holding 2nd set of clips attaching motor on transmission. Then pried off clips.

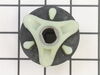

Removed old coupling from transmission shaft and motor shaft, plus middle 6 hole widget thingy.

Installed new parts on transmission shaft and motor shaft with fingers pointing towards each other. Using a small hammer, tapped the parts onto each shaft. Placed 6 hole widget thingy on the transmission part, and then rotated motor so motor part would fit in remaining three holes.

Replaced clips to hold motor on transmission and reinstalled screws holding clips.

IMPORTANT: Replace motor wire now. I forgot to do this and after the tub was filled with water, realized that, and since the pump was also disconnected, could not get the water out. Had to get wife to hold washer up while I crawled underneath to reattach motor wire. Learn from my mistake!

Attach pump onto motor and replace clips. Double check everything is back in place.

Roll washer onto front side. Attach discharge hose. Tip washer back upright. Reconnect water. Reposition discharge hose and plug washer into power.

First try it smelled like something plastic was burning, but I think that was the old part shavings getting ground away.

Pried off two clips attaching pump on motor using a flathead screwdriver. The rear clip was done by touch. Unplugged wiring plug from motor. Using an adjustable wrench (socket set would have worked better), remove two screws holding 2nd set of clips attaching motor on transmission. Then pried off clips.

Removed old coupling from transmission shaft and motor shaft, plus middle 6 hole widget thingy.

Installed new parts on transmission shaft and motor shaft with fingers pointing towards each other. Using a small hammer, tapped the parts onto each shaft. Placed 6 hole widget thingy on the transmission part, and then rotated motor so motor part would fit in remaining three holes.

Replaced clips to hold motor on transmission and reinstalled screws holding clips.

IMPORTANT: Replace motor wire now. I forgot to do this and after the tub was filled with water, realized that, and since the pump was also disconnected, could not get the water out. Had to get wife to hold washer up while I crawled underneath to reattach motor wire. Learn from my mistake!

Attach pump onto motor and replace clips. Double check everything is back in place.

Roll washer onto front side. Attach discharge hose. Tip washer back upright. Reconnect water. Reposition discharge hose and plug washer into power.

First try it smelled like something plastic was burning, but I think that was the old part shavings getting ground away.

Parts Used:

-

Ted from SOUTH MILWAUKEE, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

30 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Found cracked brake shoe

Remove the main bolts that hold the gearbox in place, pull the gearbox and shaft out. You will see the brake shoes and drum--the large spring is a struggle to replace. Getting it out was not hard. The biggest struggle I had was replacing the brake shoe spring after replacing the shoes. I ultimately compressed the spring in a vise, then used safety wired it, then placed it between the shoes, then cut the wire to relaease the spring.

Parts Used:

-

Michael from Trafalgar, IN

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

31 of 39 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water constantly dripped into washer when it was off.

Turned off water and pulled power plug, Then unscrewed hot and cold hoses from washer.

I took off the top control by undoing the 2 screws in front and then the two screws on the back plastic latches. Mover it forware and took off the 2 screws on the bottom of the back which came up and off easily. Undid the two screws holding the Water valve to the back and undid the water outlet tube and the wireing. Replaced with new valve and reattached tubing and wires. Screwed back on and reattached controls.

Actually was very easy even without repair manual to the washing machine.

I took off the top control by undoing the 2 screws in front and then the two screws on the back plastic latches. Mover it forware and took off the 2 screws on the bottom of the back which came up and off easily. Undid the two screws holding the Water valve to the back and undid the water outlet tube and the wireing. Replaced with new valve and reattached tubing and wires. Screwed back on and reattached controls.

Actually was very easy even without repair manual to the washing machine.

Parts Used:

-

MARK from MARION, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

24 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was locked up

I had a little difficulty at first, trying to remove the back of the unit. I then figured out that the repair was to be made by leaning the washer back and removing it from underneath. That became really easy as the bottom is open.I had to remove one nut and then the agitator from inside, then tilt the machine back, disconnect the two hoses from the pump, remove three bolts and lower the motor/ transmission assembly. Then I had to disconnect the motor from the pump ( with two snap on clips) and remove the broken plastic coupling. The new coupling had a metal insert that seems to make it stronger than the original piece.I then just reversed the procedure to put it together again and it worked fine. The part was shipped immediately and I got it sooner than I expected so I greatly appreciate that. Overall it went well, and by the way, it was my daughters washer and she was happy as well.Thanks, Roger

Parts Used:

-

Roger from Palmyra, IN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

24 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

In the spin cycle, drum would'nt spin unless assisted

First off unplug the machine then turned off H/C water supply and removed hoses, laid the machine on its side, removed 3 motor supp. bolts, loosened drum pulled out shaft and clutch assembly was right there. Also replaced coupling while it was apart. And to think, a svce company wanted 179.00 just to walk in my door and diagnose the pblm. Then, parts and labor were extra. Thanks for the help/advice, piece of cake!!!!!!!

Parts Used:

-

ANTHONY from NY, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

valves allowed water to overflow during the rinse cycle, sometimes took forever to fill.

I removed the screws holding the control unit down, removed a couple at the rear,

Disconnected the electrical clip that plugs into the top, under the control unit.

This allows enough slack to pivot it ( the control unit) upside down and get it out of the way enough to remove the spring clips that hold the top to the back.

Popped out the two clips that hold the back to the top.

Pulled the back out, up until the plastic soap dispenser , (which is attached to the back) hits under the lip of the top.

This does not allow enough room to get to the valves.

I finally figured out you have to lift the entire top up high enough to clear the back while pulling it ( the back) out.

Disconnected the hose clamp, electric connectors, installed the new valves into the supplied mounting plate replaced the valves .

Re -connected the hose and electric connectors and re assembled the back.

The only problem I had was when one of the spring retainers that hold the back to the top popped off and fell inside the unit, which forced me to remove everything including the back bottom screws, which caused the sides to pop off, the mounting ears , which are attached to the back,

Took some finesse but finally retrieved the spring clamp and finished everything back together.

It was a bit tricky keeping the plastic gaskets between the back and the sides from falling inside as I reassembled it.

But all is well, and would have been more difficult without the expierence written by others who posted, on the site.

Thank you to all, for the help.

I hope my efforts will help someone else.

Disconnected the electrical clip that plugs into the top, under the control unit.

This allows enough slack to pivot it ( the control unit) upside down and get it out of the way enough to remove the spring clips that hold the top to the back.

Popped out the two clips that hold the back to the top.

Pulled the back out, up until the plastic soap dispenser , (which is attached to the back) hits under the lip of the top.

This does not allow enough room to get to the valves.

I finally figured out you have to lift the entire top up high enough to clear the back while pulling it ( the back) out.

Disconnected the hose clamp, electric connectors, installed the new valves into the supplied mounting plate replaced the valves .

Re -connected the hose and electric connectors and re assembled the back.

The only problem I had was when one of the spring retainers that hold the back to the top popped off and fell inside the unit, which forced me to remove everything including the back bottom screws, which caused the sides to pop off, the mounting ears , which are attached to the back,

Took some finesse but finally retrieved the spring clamp and finished everything back together.

It was a bit tricky keeping the plastic gaskets between the back and the sides from falling inside as I reassembled it.

But all is well, and would have been more difficult without the expierence written by others who posted, on the site.

Thank you to all, for the help.

I hope my efforts will help someone else.

Parts Used:

-

Sam from Robertsville, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Although the motor was running, washer wouldn't agitate or spin.

After disconnecting the electrical supply, first remove the two screws at either end of the control panel and fold it back away from the washer top. Then, unplug the electrical lid switch connection. Now, remove the two clips at either end on top to disconnect the housing from the washer back and chassis. The motor is sandwiched between the water pump in the front and transmission at the rear. The Direct Drive Coupling connects the rear motor shaft to the transmisson. After you have taken the outter portion of the washer off, remove the two snap clips that hold the water pump in place and slide the pump off the front shaft. Best to also disconnect the upper hose connection so the pump can be moved out of the way. Caution though, remaining water in tub will drain out. Now remove the two screws that hold the clips in place which secure the motor to the transmission. Careful, as the old Direct Drive Coupling is probably destroyed, the clips are the only thing holding the motor in place and the motor needs to be supported so it won't drop to floor when the clips are removed. Be careful not to lose the four rubber grommets which sit between the motor and transmission bracket. After motor is on floor remove the old plastic slip-on direct drive coupling discs from both the motor and transmission shafts. The new replacement discs have steel centers which do not slide onto the shafts as easily as the old plastic ones did. I had to tap the center steel portion onto the shafts using a hammer and a deep wall socket the same width as the steel portion of the disc. Be careful! I'm sure that tapping the plastic portion of the disc to properly seat it on the shaft will break it away from the steel portion. In my case, It took me several attempts to completely seat the new discs. I had to do quite a bit of tapping to get the discs seated far enough onto the shafts so that the motor slipped easily against the transmission bracket grommets and the retainer clips snapped back into place easily. Reassembly is simply reversing the steps you took when taking the unit apart. Before putting the outter housing back in place, I checked to make sure everything was running smoothly by jumping out the electrical snap-in connection for the lid switch and running the machine in the spin cycle. Remember, if you don't jump out the lid switch and just try to test the unit in the aggitate cycle, the machine has to first fill with water.

Parts Used:

-

Thomas from Commack, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

20 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer drum would not stop spinning when door was opened

This dryer is a stackable washer/dryer. I removed all the buttons on the front panel along with the panel. I then was able to lift the front of the door and reach in to the door switch and plug. I unscrewed the old part, installed the new one. I then put the front panel and face plate back into position and screwed them back to the dryer casing. Lastly I put the knobs back on. I was extremely impressed at how easy it was to order and how quick the part came to my house. I am very satisfied with the service and the price and will use this site again in the future.

Parts Used:

-

Debra from Clarksburg, NJ

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

26 of 43 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!