CFLE2022MW0 Frigidaire Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Loud Squeaking

1. Unplug dryer from outlet

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum belt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum belt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

Parts Used:

-

Frank from Boyertown, PA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

334 of 351 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Thermal Limiter opened

Unplugged Dryer.

Opened top of Dryer, over the drum.

Removed Thermal Limiter.

Tested the Thermal Limiter - found it was open.

Checked all vents and exhaust tube for lint build-up.

Replaced Thermal Limiter.

Closed top of dryer.

Plugged Dryer back.

Tested Dryer - it works.

Opened top of Dryer, over the drum.

Removed Thermal Limiter.

Tested the Thermal Limiter - found it was open.

Checked all vents and exhaust tube for lint build-up.

Replaced Thermal Limiter.

Closed top of dryer.

Plugged Dryer back.

Tested Dryer - it works.

Parts Used:

-

Stephen from Newnan, GA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

242 of 318 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

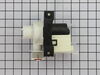

would't spin all water out or rinse out clothes

uplugged washer took front off washer 2 screws pryed up top pump was mounted with 2 screws and 2 wires took off found change in pump and the fins to pump worn off ordered part off line the wait for part was longer than the amount of time to fix problem and cost of part saved me about $25-35 if I was to buy local worth wait save money and fix problem washes like new spins and drains all water from tub.

Parts Used:

-

kenneth from willard, OH

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

167 of 203 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would not start

I found a electrical diagram and some common problems on some websites which led me to check the thermal limiters. There are two right up top near the back of the dryer - one mounted closer to the heating coils and one mounted directly to the sheet metal on the inside back of the dryer. Using an DMM on the "Ohms" setting, I checked each sensor to make sure that they were "closed" (near zero ohms). Sure enough, the sensor mounted on the back of the enclosure was open (high resistance) which prevented the dryer from starting. To confirm, I shorted the two leads going to the sensor together temporarily and wrapped them with electrical tape and then tested the dryer - it worked perfectly. The part from Part Select was ordered and shipped very quickly. Since the sheet metal screws holding the sensor on were difficult to access with the drum in place, I used small machine screws/nuts to fasten the sensor - this allowed me to tighten the nuts from the outside of the dryer, making it very easy to attach.

Parts Used:

-

Stephen from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers

99 of 106 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer squealed loudly

First, I removed the top panel which is held on at the front by pressure clips. Second, I removed the entire front panel which entailed removing 2 screws and 2 wire couplings. Third, I removed the 3 screws on the inside center of the drum which turned out to be unnecessary. Fourth, I slid the drum forward in order to access the rear bearing. Lastly, I replaced the entire bearing assembly including the shaft, bracket, bearing, grounding ball and clip. Again, probably not needed but I had ordered the parts in advance in preparation for the worst.

Parts Used:

-

Glenn from Fort Worth, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

102 of 132 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

After a full cycle the washer would not drain the water

After reading the possiblilities of problem, I determined that the drain pump was not working; therefore I ordered a new one. When I opened the washer to replace the part, I found out that the pump was working but the filter was stuffed with pieces of rubber that came out from a rug I washed. Once all the stuff was removed, the washer worked just fine. PartSelect was very gracious to accept the returned with not questions asked!! Thanks partSelect.

Parts Used:

-

sara from North Miami, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

82 of 91 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Felt pulling apart and glide not secured

For the glide, I want to advise people that to replace the entire glide you need to order two front drum glide parts as each is only half.

First, unplug the dryer. Then, open the top so that you can get access to the work area. On each side of the inside front, there is a screw that connects the front panel to the side panels. Unscrew those screws and pull the front panel until it disconnects from the side panels. Be careful as there are wires that are secured to the bottom of the top inside lip of the front panel. One set of wires goes to the light bulb in the dryer door. You don't need to disconnect the wires, but be sure you don't damage the wires by pulling the front panel too far away from the dryer.

Once you have the front panel out of the way, you can see the front drum glide. In my case, one half was loose as the plastic plugs that pop into recesses to hold the glide in place had broken off. Remove the damaged glide section and replace it with the new section, popping the plastic plugs into the recesses. Don't be afraid to slap the glide to lock the plugs in place.

For the felt, I cut the part of the old felt that was pulling away from the front panel. I then used a flat-head screwdriver and wire brush to remove as much of the old adhesive as I could. Then, using the high-heat adhesive that came with the new felt, I put a generous amount on the front panel where the felt needed to go. I used a toothpick to spread the adhesive to get maximum area coverage. I let it set for a minute or two, and then placed the new felt. I used small clamps to keep the felt in place until the adhesive had time to bond. I only kept the clamps in place for 10 minutes.

Once I removed the clamps, I let the felt continue to adhere to the front panel for 24 hours before reassembling the dryer. Again, be careful of the wires connected to the front panel as it appears very easy for them to be pinched or cut when putting the front panel back in place.

When the dryer was reassembled, I plugged it back in and have had no more troubles.

First, unplug the dryer. Then, open the top so that you can get access to the work area. On each side of the inside front, there is a screw that connects the front panel to the side panels. Unscrew those screws and pull the front panel until it disconnects from the side panels. Be careful as there are wires that are secured to the bottom of the top inside lip of the front panel. One set of wires goes to the light bulb in the dryer door. You don't need to disconnect the wires, but be sure you don't damage the wires by pulling the front panel too far away from the dryer.

Once you have the front panel out of the way, you can see the front drum glide. In my case, one half was loose as the plastic plugs that pop into recesses to hold the glide in place had broken off. Remove the damaged glide section and replace it with the new section, popping the plastic plugs into the recesses. Don't be afraid to slap the glide to lock the plugs in place.

For the felt, I cut the part of the old felt that was pulling away from the front panel. I then used a flat-head screwdriver and wire brush to remove as much of the old adhesive as I could. Then, using the high-heat adhesive that came with the new felt, I put a generous amount on the front panel where the felt needed to go. I used a toothpick to spread the adhesive to get maximum area coverage. I let it set for a minute or two, and then placed the new felt. I used small clamps to keep the felt in place until the adhesive had time to bond. I only kept the clamps in place for 10 minutes.

Once I removed the clamps, I let the felt continue to adhere to the front panel for 24 hours before reassembling the dryer. Again, be careful of the wires connected to the front panel as it appears very easy for them to be pinched or cut when putting the front panel back in place.

When the dryer was reassembled, I plugged it back in and have had no more troubles.

Parts Used:

-

Timothy from Pensacola, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers

73 of 81 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer does not get very hot, takes two cycle's to dry

removed the screws, disconnected the wires. installed the new elements replaced the wires.

Parts Used:

-

MELISSA from OKEECHOBEE, FL

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

87 of 152 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

water leaking on floor

Removed two screws at bottom of front panel, removed front panel. Used pliers to remove hose clamp on drain hose. Fished hose out of chassis and installed new hose. Tested for leaks.

Parts Used:

-

Edward from New Smyrna Beach, FL

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

60 of 76 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

pump very noisy, failing.

Disconnect water and electricity.

Shop-vac out the water in the internal drain hose.

Remove back cover, tip washer on side to gain access.

Un-clamp rubber drain hose,unscrew pump and remove.

Cleanout filter cup (yuk!) find coins and hairpins.

Attach drain hose to new pump and re-install with hose clamps from hardware store because spring clamps were impossible (arthritis in fingers).

Reconnect water and electricity.

Test for leaks and tighten clamps if necessary.

Shop-vac out the water in the internal drain hose.

Remove back cover, tip washer on side to gain access.

Un-clamp rubber drain hose,unscrew pump and remove.

Cleanout filter cup (yuk!) find coins and hairpins.

Attach drain hose to new pump and re-install with hose clamps from hardware store because spring clamps were impossible (arthritis in fingers).

Reconnect water and electricity.

Test for leaks and tighten clamps if necessary.

Parts Used:

-

John from Mason, MI

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

51 of 55 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer overheated and stopped working

The first thing I did was cheked the electrical panel and breaker, then I checked the electrical cord, then I did check the motor on the bottom of the machine (that may be is the blower motor) looking for any indication of burned parts or broken, then I checked the on-off switch with a voltmeter looking for continuity and it was fine. Then I checked the timer switch and it was fine as well. Finally, I took the lid off the top of the dryer machine to check the thermostat and themal limiter fuse. The thermostat was fine but the thermal fuse was open. So after doing some research to understand how the fuse work I decided to place an order to get a new fuse. I installed it and the dryer started working again. After replacing the fuse I monitored the dryer machine while operating it and worked fine. Why the fuse was open or was damaged? It is the first time I have problems w/ the dryer. I checked the end of the conduct line that guide the air out and I noticed and have to clean the end of it because it was dirt. Because it was not completly clean, the dryer got overheated. It took me sometime to figure out the problem but I learned, save me money and the best part was that I do it myself : )

Parts Used:

-

Paul from Holiday, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

34 of 36 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Door Latch & Door Strike Broken On Dryer

I removed the broken door latch & strike with pliers. Then I pushed the new parts into place

Parts Used:

-

Bruce from Seminole, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Pliers

41 of 59 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

My husband ruined the old latch by trying to shut the door too hard, and the old latch fell down into the inside of the dryer.

I took the new latch out of the package and snapped it into place. It took about 15 seconds, and that included the walk to the laundry room!

Parts Used:

-

Michelle from Dallas, TX

-

Difficulty Level:Really Easy

-

Total Repair Time:Less than 15 mins

28 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The washer would not drain

After removing the front of the washer, I used slip joint pliers for the hose clamps, then a screwdriver for the mount bolts and replaced the pump motor in reverse order. The pump was ordered on line on a Friday before 10am and was delivered on saturday moring by FedEx. I could not have expected such fast and efficent service!

Great Job!!

Great Job!!

Parts Used:

-

Harry from Zephyrhills, FL

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

24 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

discharge of water out of wash machine

remove side panel & start rinse cycle & heard a grinding noise in discharge pump. used a bucket to catch water upon removeal of discharge hose to pump. unplug disconnect plug to motor, remove pump from unit. Discovered propeller was loose in housing. Googled Partselect.com, odered part & in 2 days later installed new pump on unit. Started a load of wash & it has been working perfect ever since. thanks to PartSelect.com for the service, the repair was minimal & easy for the DO IT YOURSELFER. Bill Starry

Parts Used:

-

William from York Springs, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers

26 of 33 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!