LTE6234AW1 Whirlpool Washer Dryer Combo - Instructions

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Timer stuck in on position during drying cycle.

I removed the front control cover, disconnected the timer wires which were color coded, and replaced the new timer. Checked for system operation and everything worked fine.

Parts Used:

-

David from Erie, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

32 of 46 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer not spinning

I took off the front panel via 2 screws on the inside of the dryer with the top panel in the maintenance position. Pulled out the tub(cut my hand pretty bad in the process but continued). Did some cleaning and I had to google how the belt tensioner goes into place. Rather difficult on your own i held the belt and placed the tub back into place while placing the belt around the tub putting it in the correct area. thats pretty much it and began reinstalling the parts i had removed.. easy fix now that i have done it once. This is all after my landlords said they werent replacing it and just to have this one hauled off, so all in all i have a 26 dollar dryer now:)

Parts Used:

-

john from goldsboro, NC

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

32 of 47 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Water constantly dripped into washer when it was off.

Turned off water and pulled power plug, Then unscrewed hot and cold hoses from washer.

I took off the top control by undoing the 2 screws in front and then the two screws on the back plastic latches. Mover it forware and took off the 2 screws on the bottom of the back which came up and off easily. Undid the two screws holding the Water valve to the back and undid the water outlet tube and the wireing. Replaced with new valve and reattached tubing and wires. Screwed back on and reattached controls.

Actually was very easy even without repair manual to the washing machine.

I took off the top control by undoing the 2 screws in front and then the two screws on the back plastic latches. Mover it forware and took off the 2 screws on the bottom of the back which came up and off easily. Undid the two screws holding the Water valve to the back and undid the water outlet tube and the wireing. Replaced with new valve and reattached tubing and wires. Screwed back on and reattached controls.

Actually was very easy even without repair manual to the washing machine.

Parts Used:

-

MARK from MARION, MA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

24 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

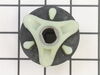

craked blower motor

somthing fell down in the blower motor compartment and busted up the bloewr motor fan,and was making noise and out of balance.i changed the blower motor and runs like a charme

Parts Used:

-

joe from cheswick, PA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

63 of 142 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Agitator was locked up

I had a little difficulty at first, trying to remove the back of the unit. I then figured out that the repair was to be made by leaning the washer back and removing it from underneath. That became really easy as the bottom is open.I had to remove one nut and then the agitator from inside, then tilt the machine back, disconnect the two hoses from the pump, remove three bolts and lower the motor/ transmission assembly. Then I had to disconnect the motor from the pump ( with two snap on clips) and remove the broken plastic coupling. The new coupling had a metal insert that seems to make it stronger than the original piece.I then just reversed the procedure to put it together again and it worked fine. The part was shipped immediately and I got it sooner than I expected so I greatly appreciate that. Overall it went well, and by the way, it was my daughters washer and she was happy as well.Thanks, Roger

Parts Used:

-

Roger from Palmyra, IN

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

24 of 28 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Motor was working and rotating lower portion of agitator, but the top was not spinning.

1. Remove the fabric softener receptacle

2. Remove the plastic dome shaped separator with a rubber o-ring around it (directly beneath fabris softener receptacle)

3. There is an 11mm bolt right in the center. Use socket wrench to remove bolt.

4. Remove agitator from washign machine.

5. Separate top half of agitator from bottom half (this was the most difficult part for me; unlike others who have described this repair, mine would not simply pull apart; I spent quite a while trying to pry up the white plastic clips extending from the bottom piece through the clear plastic piece that covers the "dog teeth" that make the top piece agitate)

6. Once apart, replace worn "dog teeth" with new dog teeth.

7. Put back together in reverse order.

2. Remove the plastic dome shaped separator with a rubber o-ring around it (directly beneath fabris softener receptacle)

3. There is an 11mm bolt right in the center. Use socket wrench to remove bolt.

4. Remove agitator from washign machine.

5. Separate top half of agitator from bottom half (this was the most difficult part for me; unlike others who have described this repair, mine would not simply pull apart; I spent quite a while trying to pry up the white plastic clips extending from the bottom piece through the clear plastic piece that covers the "dog teeth" that make the top piece agitate)

6. Once apart, replace worn "dog teeth" with new dog teeth.

7. Put back together in reverse order.

Parts Used:

-

Brad from Boise, ID

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Socket set

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washer stopped before rinse cycle

My husband actually did the repairs all I know is he removed the lid, removed the old switch and put in the new one. My washer works now and thats all I care about. I thank you for having the part and at a reasonable cost we were able to repair our washer considering it is twin stackable and is over 10 years old.

Thanks again!!!!

Thanks again!!!!

Parts Used:

-

Pam from San Diego, CA

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Screw drivers, Wrench (Adjustable)

74 of 180 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

In the spin cycle, drum would'nt spin unless assisted

First off unplug the machine then turned off H/C water supply and removed hoses, laid the machine on its side, removed 3 motor supp. bolts, loosened drum pulled out shaft and clutch assembly was right there. Also replaced coupling while it was apart. And to think, a svce company wanted 179.00 just to walk in my door and diagnose the pblm. Then, parts and labor were extra. Thanks for the help/advice, piece of cake!!!!!!!

Parts Used:

-

ANTHONY from NY, NY

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

22 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Tub did not center and seal was hanging out of tub

Laid washer on front side and removed top spring, then lifted the tub assembly to replace the right side spring, the one behind the motor was the hardest, I lifted the tub then removed the spring bracket at the tub with pliers and a socket. The top seal all I had to do was take the 4 screws that hold the top on (it takes a long extension) then sit it bak up and I lifted the top up to give me enough room to unsnap the top piece of the tub, cleaned it up put seal in. The parts fit perfitlt and real fast shipping, I bookmarked the site and will buy from again. JIM

Parts Used:

-

James from Nelsonville, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Socket set

22 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Cog stripped causing agitator to not turn

Removed top cap on agitator w/ flathead screwdriver. Removed protective cap over bolt and cog housing shaft. Used 7/16 deep socket w/ extension to remove bolt. Removed housing where stripped cogs were located. Cogs seated loosely in shaft housing no tools required to remove cogs. Replaced cogs in housing, made sure everything was lined correctly. re-inserted housing into shaft. ,screwed bolt, replaced caps and works like new.

Parts Used:

-

Vicki from Houston, TX

-

Difficulty Level:Easy

-

Total Repair Time:Less than 15 mins

-

Tools:Screw drivers, Wrench set

22 of 25 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

valves allowed water to overflow during the rinse cycle, sometimes took forever to fill.

I removed the screws holding the control unit down, removed a couple at the rear,

Disconnected the electrical clip that plugs into the top, under the control unit.

This allows enough slack to pivot it ( the control unit) upside down and get it out of the way enough to remove the spring clips that hold the top to the back.

Popped out the two clips that hold the back to the top.

Pulled the back out, up until the plastic soap dispenser , (which is attached to the back) hits under the lip of the top.

This does not allow enough room to get to the valves.

I finally figured out you have to lift the entire top up high enough to clear the back while pulling it ( the back) out.

Disconnected the hose clamp, electric connectors, installed the new valves into the supplied mounting plate replaced the valves .

Re -connected the hose and electric connectors and re assembled the back.

The only problem I had was when one of the spring retainers that hold the back to the top popped off and fell inside the unit, which forced me to remove everything including the back bottom screws, which caused the sides to pop off, the mounting ears , which are attached to the back,

Took some finesse but finally retrieved the spring clamp and finished everything back together.

It was a bit tricky keeping the plastic gaskets between the back and the sides from falling inside as I reassembled it.

But all is well, and would have been more difficult without the expierence written by others who posted, on the site.

Thank you to all, for the help.

I hope my efforts will help someone else.

Disconnected the electrical clip that plugs into the top, under the control unit.

This allows enough slack to pivot it ( the control unit) upside down and get it out of the way enough to remove the spring clips that hold the top to the back.

Popped out the two clips that hold the back to the top.

Pulled the back out, up until the plastic soap dispenser , (which is attached to the back) hits under the lip of the top.

This does not allow enough room to get to the valves.

I finally figured out you have to lift the entire top up high enough to clear the back while pulling it ( the back) out.

Disconnected the hose clamp, electric connectors, installed the new valves into the supplied mounting plate replaced the valves .

Re -connected the hose and electric connectors and re assembled the back.

The only problem I had was when one of the spring retainers that hold the back to the top popped off and fell inside the unit, which forced me to remove everything including the back bottom screws, which caused the sides to pop off, the mounting ears , which are attached to the back,

Took some finesse but finally retrieved the spring clamp and finished everything back together.

It was a bit tricky keeping the plastic gaskets between the back and the sides from falling inside as I reassembled it.

But all is well, and would have been more difficult without the expierence written by others who posted, on the site.

Thank you to all, for the help.

I hope my efforts will help someone else.

Parts Used:

-

Sam from Robertsville, MO

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers

22 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

tub off center, rubbing on outer tub in spin

turned the washer on it's back and shoved the tub to the side to release pressure on a spring ,pulled it loose and installed new one. this worked for the back two then turned washer on it;s face and repeted the process on the front spring.

Washer works great now.

Washer works great now.

Parts Used:

-

Charles from Rose Bud, AR

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers

21 of 24 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Slipping Spin clutch due to leaking gear-case seal.

1. Unplug the machine.

2. Turn the water off.

3. Disconnect the supply and discharge hoses.

4. Open the cover and remove the cap/cover of the agitator. Use socket wrench to remove the bolt securing the agitator. Pull up on the agitator and remove it.

5. Lay washing machine down on it's front. Remove the inlet and outlet drain hoses from the discharge pump.

6. Remove the 2 "faston" connectors from the motor start capacitor (looks like a D cell flashlight battery). Rock the connectors back and forth and pull gently until they come off. Polarity doesn't matter but to be safe make note of the positions.

7. Press the release clip on the motor connector and pull to disconnect it. Move the wiring harness out of harms way.

8. Remove the 3 bolt securing the motor and transmission assembly to the bottom of the tub. Pull the drive assembly out of the machine and place it on a suitable work surface.

9. Examine the tub brake assembly (still on the bottom of the tub), the clutch assembly (on the motor/transmission assembly you just removed and everything else for wear or damage. Now if you decide to proceed with repair continue with the following steps. If not you're done.

10. Remove the inverted cup washer from the agitator shaft of the assembly. Remove the "U" clip from the shaft and remove the clutch mechanism from the drive assembly. Make a sketch of the position of each of the removed components to aid in reassembly.

11. Now you can see the gear case cover and it's seal. If it is leaking (as mine was) you will need to replace it.

12. With the assembly level remove the bolts around the cover and remove the cover. Place the cover on a flat surface and with a screwdriver or punch drive the old seal out of the cover from the outside in.

13. Clean the seal area and check for damage. Clean the cover and transmission housing surfaces of old gasket material. There is a factory sealant available for reassembly but I chose an automotive RTF @ $4 vs $24 and it worked OK.

14. Installing the seal requires some tools and experience to done successfully. The right size sockets or piece of pipe, coupled with an arbor press or vise will get the seal in. The cover is delicate so if in doubt find a machine shop.

15. Support the outside of the cover on a hard surface and with a socket or short pipe length, PRESS (don't hammer) the new seal into the gear case cover.

16. Make sure there is lubricant in the gear case. Not overflowing but maybe 1/2 full when view with cover off on a level surface.

17. Apply some RTV sealant to trhe cover and install it. Tighten bolts evenly. Light torque (1-2 ft-lb).

18. Reassemble washing machine and test for leaks and proper operation.

2. Turn the water off.

3. Disconnect the supply and discharge hoses.

4. Open the cover and remove the cap/cover of the agitator. Use socket wrench to remove the bolt securing the agitator. Pull up on the agitator and remove it.

5. Lay washing machine down on it's front. Remove the inlet and outlet drain hoses from the discharge pump.

6. Remove the 2 "faston" connectors from the motor start capacitor (looks like a D cell flashlight battery). Rock the connectors back and forth and pull gently until they come off. Polarity doesn't matter but to be safe make note of the positions.

7. Press the release clip on the motor connector and pull to disconnect it. Move the wiring harness out of harms way.

8. Remove the 3 bolt securing the motor and transmission assembly to the bottom of the tub. Pull the drive assembly out of the machine and place it on a suitable work surface.

9. Examine the tub brake assembly (still on the bottom of the tub), the clutch assembly (on the motor/transmission assembly you just removed and everything else for wear or damage. Now if you decide to proceed with repair continue with the following steps. If not you're done.

10. Remove the inverted cup washer from the agitator shaft of the assembly. Remove the "U" clip from the shaft and remove the clutch mechanism from the drive assembly. Make a sketch of the position of each of the removed components to aid in reassembly.

11. Now you can see the gear case cover and it's seal. If it is leaking (as mine was) you will need to replace it.

12. With the assembly level remove the bolts around the cover and remove the cover. Place the cover on a flat surface and with a screwdriver or punch drive the old seal out of the cover from the outside in.

13. Clean the seal area and check for damage. Clean the cover and transmission housing surfaces of old gasket material. There is a factory sealant available for reassembly but I chose an automotive RTF @ $4 vs $24 and it worked OK.

14. Installing the seal requires some tools and experience to done successfully. The right size sockets or piece of pipe, coupled with an arbor press or vise will get the seal in. The cover is delicate so if in doubt find a machine shop.

15. Support the outside of the cover on a hard surface and with a socket or short pipe length, PRESS (don't hammer) the new seal into the gear case cover.

16. Make sure there is lubricant in the gear case. Not overflowing but maybe 1/2 full when view with cover off on a level surface.

17. Apply some RTV sealant to trhe cover and install it. Tighten bolts evenly. Light torque (1-2 ft-lb).

18. Reassemble washing machine and test for leaks and proper operation.

Parts Used:

-

Thomas from Pascoag, RI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set

20 of 22 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Idler Pulley broke

I disconnect the power, then the vent pipe. I removed the back panel of the dryer to access the pulley and removed the belt. Replaced the back and put everything back together.

Parts Used:

-

Keith from Richmond, VA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

21 of 26 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The spin gear was striped.

I had to take the motor and transmission out. They are one piece. Removed the clutch, take off trans. cover, remove a snap ring, take the striped gear off, and put the new one on. Then put put everything back on the way it came off.

Parts Used:

-

Aaron from Lake Mills, WI

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Socket set

21 of 27 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!