Product Description

Idler Pulley Wheel and Bearing Specifications

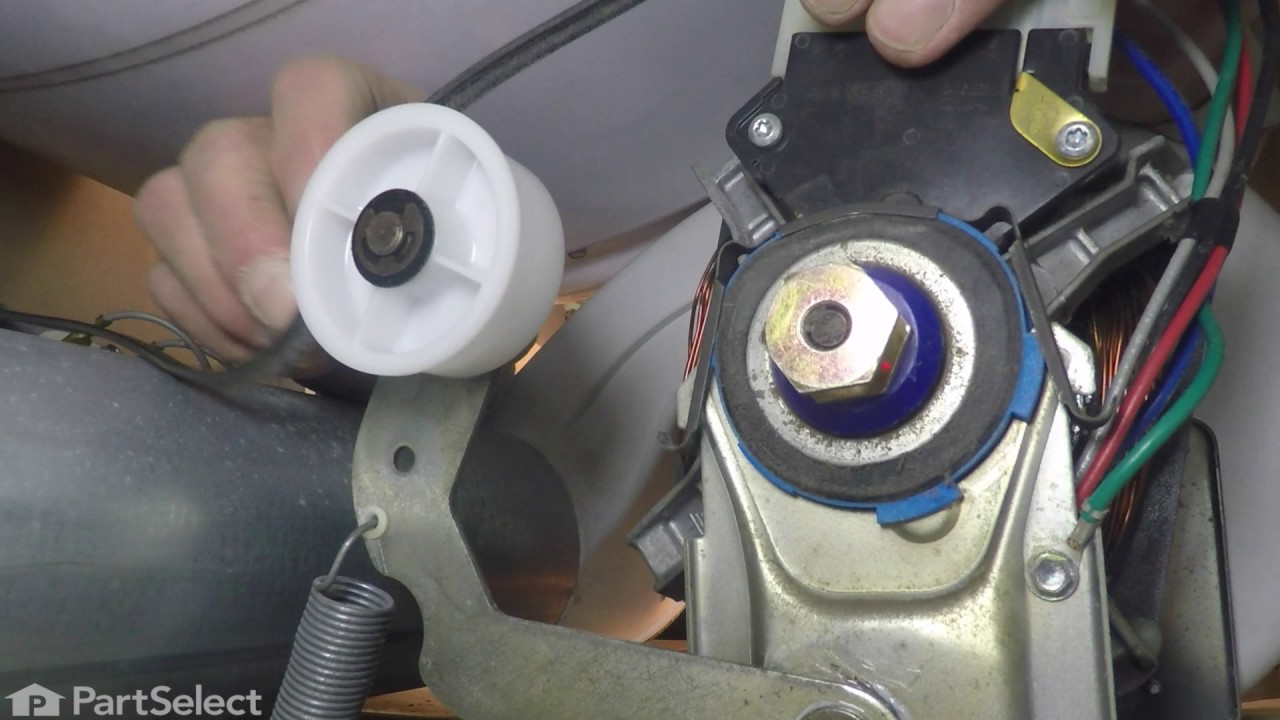

This idler pulley wheel is white and made of plastic. It is two inches in diameter and comes with a center bearing.

How Buying OEM Parts Can Save You Time and Money

Part Videos

Replacing your Maytag Dryer Idler Pulley Wheel and Bearing

Replacing your Maytag Dryer Idler Pulley Wheel and Bearing

Troubleshooting

This part fixes the following symptoms:

Noisy

This part works with the following products:

Dryer, Washer Dryer Combo.

This part works with the following products:

Maytag, International, Crosley.

Part# WP6-3700340 replaces these:

AP6009859, 33001783, 6-3700340, WP6-3700340VP

Customer Reviews

Filter By Rating:

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Nikola C - October 7, 2020

Verified Purchase

The part fit as expected

The part arrived on time and in as-advertised condition. It looked exactly the same as the original part, only new. I hope it's also going to be of original quality, but... only time will tell :-)

Greg D - August 27, 2019

Verified Purchase

Easy repair

The part was delivered quickly. Very easy to order. Thank you for the great service.

Brian T - June 25, 2019

Verified Purchase

The correct part, delivered quickly at a reasonable price.

The order system was comprehensive, easy to follow and find the correct part.The price was reasonable and delivery was spectaularly fast. There is not much else to say. If all on line retailers worked like this the world would be vastly better than it is now.

Walid A - May 30, 2019

Verified Purchase

Fit exactly

Thanks for the part. It matched perfectly and arrived early

Domenico A - May 28, 2019

Verified Purchase

Worked as expected

The video was great

James M - April 30, 2019

Verified Purchase

Did The Job Perfectly!

This part was perfect for our fix. Thankful for all of the helpful how to videos as well! Fast delivery and overall a great experience for our first order. Thank you!

Morgan W - November 6, 2018

Verified Purchase

Easy repair and worked as expected.

The best part was the pulley being ordered in the afternoon with a 3-5 day delivery. Part arrived by 10:30 the next morning. Thanks.

- < Prev

- 1

- Next >

Customer Repair Stories

Average Repair Rating: 2.9 / 5.0, 64 reviews.

What's this?

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Motor buzzed and dryer drum would not spin when pressing start

From the first time the motor buzzed (but dryer tumbler then started to turn), 2 weeks elapsed for the dryer drum to stop turning altogether. If this occurs, DO NOT continue to push the start button because the motor armature wiring will heat up and the insulation will begin to melt and smell - a SAFETY HAZARD. Unplug dryer and lockout/tagout as appropriate.

Through basic troubleshooting, discovered the motor had seized up. Since the unit was about 10 years old and it had to be disassembled for replacement, the decision was made to replace "likely to fail mechanical components including motor, belt, both rear drum rollers/shafts, idler arm pulley/assembly/wheel, associated washers, snap rings and both front glides. Reviewed the PartSelect website and drawings, ordered the parts and they delivered on time. Buy the correct sized snap rings at a local hardware, they're much less expensive. Also once inside your dryer, you'll likely find alot of lint to vacuum out...have fun.

I went online and Googled several resources that showed how to remove the front dryer panels, as well as PartSelect repair stories. From that point on, I took photos as I was disassembling so I would know how to put it back together. Utilize pictures or whatever system you prefer to keep track of taking something apart and putting it back together.

Remove the dryer door, then the front panel Disconnect wires to the light, dryness sensor and door switch. Note belt and pulley configuration that is near the motor-this will help you later when reinstalling the belt. Also note if the ribbed side or the flat side of the belt is against the outer drum wall. Remove the door shroud.

Slip the belt off the idler pulley wheel. Remove front drum support, then dryer drum Note which end of the dryer drum is the front and the orientation of the glides on the drum support. Discard old belt. Drill out and remove the old front glide supports, then install/rivet the new glides.

Remove both old rear drum rollers/shafts, washers, etc. The rear drum roller shafts are secured to a back bracket by a hex nut....feel around you'll figure it out. Replace new roller shafts. Lightly grease using a high quality silicon grease, then replace new washers, roller, snap ring, etc

Carefully unplug wiring harness on motor, there are fragile clips on each end. Don't forget a separate ground wire from the harness is attached to the motor mount bracket. Carefully release tension on the idler arm spring. Using the correct size nut driver, remove three screws (on this model) then take out the motor/idler arm assembly. Remove the old idler arm/pulley assembly. Remove the motor mount clips on each end of the mount (I used a wide blade screwdriver). Remove and replace the motor. Motor configurations changed after Whirlpool bought Maytag, so orient it correctly insuring mounting gasket "nubs" on each end of the motor correspond to the cutouts on the motor mount. Reinstall the motor mount clips. Replace the new idler arm assembly/pulley wheel; grease moving parts with high quality wheel bearing grease. Replace motor/mount bracket assembly back into the dryer. Replace ground wire to motor mount bracket and plug wiring harness back in. Reinstall idler arm spring.

Place belt back on the dryer drum and move into place on rear rollers. Reinstall front drum support. Dryer drum should turn relatively easy. Insure belt is oriented on the drum correctly before connecting belt to motor shaft end and idler arm wheel pulley (the picture you took comes in handy here).

Reinstall the rest of the parts in reverse.

Through basic troubleshooting, discovered the motor had seized up. Since the unit was about 10 years old and it had to be disassembled for replacement, the decision was made to replace "likely to fail mechanical components including motor, belt, both rear drum rollers/shafts, idler arm pulley/assembly/wheel, associated washers, snap rings and both front glides. Reviewed the PartSelect website and drawings, ordered the parts and they delivered on time. Buy the correct sized snap rings at a local hardware, they're much less expensive. Also once inside your dryer, you'll likely find alot of lint to vacuum out...have fun.

I went online and Googled several resources that showed how to remove the front dryer panels, as well as PartSelect repair stories. From that point on, I took photos as I was disassembling so I would know how to put it back together. Utilize pictures or whatever system you prefer to keep track of taking something apart and putting it back together.

Remove the dryer door, then the front panel Disconnect wires to the light, dryness sensor and door switch. Note belt and pulley configuration that is near the motor-this will help you later when reinstalling the belt. Also note if the ribbed side or the flat side of the belt is against the outer drum wall. Remove the door shroud.

Slip the belt off the idler pulley wheel. Remove front drum support, then dryer drum Note which end of the dryer drum is the front and the orientation of the glides on the drum support. Discard old belt. Drill out and remove the old front glide supports, then install/rivet the new glides.

Remove both old rear drum rollers/shafts, washers, etc. The rear drum roller shafts are secured to a back bracket by a hex nut....feel around you'll figure it out. Replace new roller shafts. Lightly grease using a high quality silicon grease, then replace new washers, roller, snap ring, etc

Carefully unplug wiring harness on motor, there are fragile clips on each end. Don't forget a separate ground wire from the harness is attached to the motor mount bracket. Carefully release tension on the idler arm spring. Using the correct size nut driver, remove three screws (on this model) then take out the motor/idler arm assembly. Remove the old idler arm/pulley assembly. Remove the motor mount clips on each end of the mount (I used a wide blade screwdriver). Remove and replace the motor. Motor configurations changed after Whirlpool bought Maytag, so orient it correctly insuring mounting gasket "nubs" on each end of the motor correspond to the cutouts on the motor mount. Reinstall the motor mount clips. Replace the new idler arm assembly/pulley wheel; grease moving parts with high quality wheel bearing grease. Replace motor/mount bracket assembly back into the dryer. Replace ground wire to motor mount bracket and plug wiring harness back in. Reinstall idler arm spring.

Place belt back on the dryer drum and move into place on rear rollers. Reinstall front drum support. Dryer drum should turn relatively easy. Insure belt is oriented on the drum correctly before connecting belt to motor shaft end and idler arm wheel pulley (the picture you took comes in handy here).

Reinstall the rest of the parts in reverse.

Other Parts Used:

-

Frederick W. from Austin, TX

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Screw drivers, Wrench set

198 of 280 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeeling on startup and intermittently during use

First, I read reviews on this forum. Great help! I was betting, from previous reviews, that it was a drum roller. I took everything apart prior to ordering any parts. Sure enough, one drum roller was seized on the roller shaft. Decided to replace all rotating parts (rollers,shafts, belt, idler pulley) while everything was apart. I also took the opportunity to clean out all of the lint (there was a lot) from the motor and intake.

Parts were on my doorstep in two days. The dryer is like brand new. I could do this job again in less than an hour. This was money and time well spent.

Parts were on my doorstep in two days. The dryer is like brand new. I could do this job again in less than an hour. This was money and time well spent.

Other Parts Used:

-

Larry from Panama City Beach, FL

-

Difficulty Level:Easy

-

Total Repair Time:More than 2 hours

-

Tools:Screw drivers, Socket set

71 of 82 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

dryer was noisy, tumbler rollers and shafts wore out

disassembled dryer and removed and replaced rollers and shafts and installed new belt while i was at it. very easy fix, ordered parts from PARTS ELECT.COM , excellent website with great views of my machine made it east to order correct parts.very fast delivery , will use partselect again! HIGHLY RECOMMEND

Other Parts Used:

-

jim from chesaning, MI

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Socket set, Wrench set

47 of 1405 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Idler Pulley worn, squeaking

Did an on-line search on Matag dis-assembly, pulled front panel, dryer drum, replaced idler pulley, rollers and belt. Also, vacuumed dryer cabinet , now the dryer works like new. This is an easy repair for anyone with any mechanical ability, and just basic tools.

Other Parts Used:

-

Charles from Port Jefferson, NY

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers

46 of 1402 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

The drier tumbler stopped spinning, and my wife noticed a burning smell when it ran.

1) Took off the front door of the drier (first unscrewed it in the sides, then lifted the door to lift the hinges up and pulled the door off)

2) Pulled the front panel down and off

3) I checked the belt to see if it was broken and it wasn't

4) I tried to turn the drier barrel manually to see if I can move the belt... it didn't move. Not knowing if there was just too much resistance, I tested the drier while looking at the motor and motor pulley as it ran.

5) I noticed that the motor pinion rotated, but the belt was slipping against it... that's why it smelled. The rubber was burning

6) Then I found that the idler pulley had stopped rotating, and the belt actually cut a channel into part of the plastic... That's when I realized that I had to replace at least the idler pulley.

7) Not knowing whether the bushing and other parts were going to be salvageable, I ordered parts for the whole assembly... but I wasn't sure how to best approach the repair...

8) Then I found partselect.com, and they had both diagrams of the assembly, all the parts easy to order, and best of all, a video of someone actually going through this repair! I was dumbfounded! :)

9) For swapping the parts I just watched the video on how to pull out the drier barrel... the only difference is that I didn't see a need to unplug the cables from the front top panel before removing the drier tumbler. (Obviously the power was turned off :P)

10) when I removed the barrel, I swapped the whole idler pulley assembly, just keeping the original spring.

11) Put everything back together, and it ran like a champ!

The video helped me save a lot of time though... it showed me how the whole thing is most easily serviced and made the repair a breeze!

2) Pulled the front panel down and off

3) I checked the belt to see if it was broken and it wasn't

4) I tried to turn the drier barrel manually to see if I can move the belt... it didn't move. Not knowing if there was just too much resistance, I tested the drier while looking at the motor and motor pulley as it ran.

5) I noticed that the motor pinion rotated, but the belt was slipping against it... that's why it smelled. The rubber was burning

6) Then I found that the idler pulley had stopped rotating, and the belt actually cut a channel into part of the plastic... That's when I realized that I had to replace at least the idler pulley.

7) Not knowing whether the bushing and other parts were going to be salvageable, I ordered parts for the whole assembly... but I wasn't sure how to best approach the repair...

8) Then I found partselect.com, and they had both diagrams of the assembly, all the parts easy to order, and best of all, a video of someone actually going through this repair! I was dumbfounded! :)

9) For swapping the parts I just watched the video on how to pull out the drier barrel... the only difference is that I didn't see a need to unplug the cables from the front top panel before removing the drier tumbler. (Obviously the power was turned off :P)

10) when I removed the barrel, I swapped the whole idler pulley assembly, just keeping the original spring.

11) Put everything back together, and it ran like a champ!

The video helped me save a lot of time though... it showed me how the whole thing is most easily serviced and made the repair a breeze!

Other Parts Used:

-

Mark from Shelburne, VT

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Screw drivers, Socket set

40 of 1348 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeaking noise when dryer was on! Very annoying!

If your dryer is squeaking it is most likely either the idler pulley or drum rollers. First I took apart the dryer to see which parts I would need. I checked the drum rollers by spinning them with my hand to see if they spun freely and also checked them to see if they were loose, they were okay. Then I checked the idler pulley and found my problem, it was hard to spin it so I figured the bearing was shot. I sprayed some lubricant on the bearing to help with the squeaking while I waited for my parts. It took about 30 minutes to diagnose my problem and put the dryer back together.

I took some advise from another story saying to get the whole idler arm, shaft and pulley assembly. It might have cost me a few bucks more, but I did not want to run into the same problem he did (the pulley bearing was fused to the shaft). It took me about 20 minutes to take apart the dryer, install the part, and put it back together. If you are pretty good with fixing things, you should have no problem doing this repair.

I took some advise from another story saying to get the whole idler arm, shaft and pulley assembly. It might have cost me a few bucks more, but I did not want to run into the same problem he did (the pulley bearing was fused to the shaft). It took me about 20 minutes to take apart the dryer, install the part, and put it back together. If you are pretty good with fixing things, you should have no problem doing this repair.

Other Parts Used:

-

Scott from Davie, FL

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:15 - 30 mins

-

Tools:Nutdriver, Screw drivers

33 of 34 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Metal on Metal Squealing Noise

After taking the dryer apart, I found that one of the drum support rollers was barely hanging on the pin and was the main cause of the metal on metal squealing noise that became increasingly worse over a month's time.

I replaced both rollers, the idler pulley, and put on a new belt after giving the dryer a thorough cleaning.

It was a 100% success and fixed the problem making the dryer work and sound like brand new again.

I replaced both rollers, the idler pulley, and put on a new belt after giving the dryer a thorough cleaning.

It was a 100% success and fixed the problem making the dryer work and sound like brand new again.

Other Parts Used:

-

John from Bethlehem, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Pliers, Screw drivers, Socket set

33 of 35 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Blower wheel broke

Replaced bower wheel, drum rollers,belt and Idler pulley while the dryer was apart. so far so good. Easy repair

Motor bearings seemed tight so hopefully will get another ten years out of dryer.

Motor bearings seemed tight so hopefully will get another ten years out of dryer.

Other Parts Used:

-

Mary Beth from Lake St. Louis, MO

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers

25 of 655 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud screeching noise

I watched the very helpful video provided by Parts Select. The repair went smoothly except for two problems. After reassembly, there was still a noise coming from the rotating drum, which I later discovered was the result of not making sure the felt gaskets around the front and back edges of the drum were not being pinched. Smoothing the felt solved the problem. The other issue was that after the repair the dryer was shutting off prematurely, before the clothes were completely dry. This was again my fault. When I first removed the bulkhead, a wire to the automatic moisture sensor came loose without my noticing it, hiding itself deep inside the cabinet. Since the model used on the video did not have such a sensor, disconnecting/reconnecting the wire was not mentioned. Upon reopening the cabinet, I noticed the loose wire and reconnected it -- problem solved. Thanks Parts Select, and thanks to the other user reports that provided useful tips.

Other Parts Used:

-

Cameron from Kerhonkson, NY

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers

23 of 716 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Installation of parts solved the difficulty!

I watched all of the video provided for repairing each of the parts and used them several times! They were excellent and beneficial! I used the suggestions provided and found the involved correction to do exactly as planned. The end result was very good and the dryer now works like it is supposed to without any noises. I thank you for all of your help.

Other Parts Used:

-

Howard G from Washington, PA

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Pliers, Screw drivers, Wrench (Adjustable), Wrench set

22 of 700 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- 2

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Anna

July 20, 2017

My dryer is making obnoxiously loud noises but as the cycle keeps going the noises tend to calm down until they just completely stop. I was told squeaking noises are directly related to the idler pulley? With this purchase do I need to get anything else? Or will it all come together?

Hi Anna, the idler pulley WPW10547292 for your dryer comes as a complete assembly, it includes everything you will need for a successful installation. I would also recommend ordering some turbine oil TJ93240 at the same time. Apply a small amount to the idler pulley bearing, the drum rollers, and the blower wheel bearing. This will help everything rotate smoothly. Good luck with your repair.

8 people found this helpful.

Was this helpful?

Thank you for voting!

Ryan

February 6, 2018

The idler pulley flew off my dryer! I can't find a snap ring or washer inside so i need either or does the bearing snap on and hold the pulley in place?

For model number MLE2000AYW

Hi Ryan,

Thank you for your question. No, there is a retaining ring that holds the part on the pulley arm. I have listed that part in a link down below for you. Good luck with your repair.

3 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

David

April 16, 2018

Dryer makes a constant screeching sound when power on. With power off and I manually turn drum the noise is apparent. What part do you think I need? Cost? Thank you

For model number WED7600XW0

Hi David, Thank you for the question. There are a few parts to check. You can check the Drum Support Rollers, PartSelect Number: PS11752609, Drum Support Shafts, PartSelect Number: PS11753708 or PartSelect Number: PS11753707 depending on the threads. The Idler Pulley Wheel and Arm, PartSelect Number: PS11756154 and the drive belt, PartSelect Number: PS11746374. You can look for wear and damage on this parts. Hope this helps!

3 people found this helpful.

Was this helpful?

Thank you for voting!

Dex

July 20, 2017

My dryer is experiencing intense vibrations during cycle. It only happens when the drum is turning. Rollers are good. Where should I look next?

Hello Dex, thanks for the question. You will need to inspect the blower wheel, it is fairly common for lint to build up or get stuck inside the fins of the blower wheel, which will cause the excess vibrations. I hope this helps, if you have any further questions please let us know.

2 people found this helpful.

Was this helpful?

Thank you for voting!

Paul

January 14, 2018

Dryer was and continues to make chirping noises. I ordered and changed the two rear drum support wheels and one shaft for the right support wheel. Also changed the two front glide strips as well as the belt. While I had everything apart, I took the opportunity to remove and clean the idler pulley bearing and shaft. Put everything back together and its making the same chirping noise as before. I guess i should have replaced the idler pulley bearing instead of just cleaning it? Any other possibilities?

For model number MDE2500AYW

Hello Paul,

Thanks for your question. Given all of the other parts you have replaced, we would also advise replacing the idler pulley bearing to see if that fixes the chirping noise. If that does not work, it could be the motor as well, but that should be a last resort given how core of a component the motor is.

I hope this helps.

2 people found this helpful.

Was this helpful?

Thank you for voting!

Related Parts:

Evie

July 20, 2017

My dryer is too hot during all cycles including delicates. When I removed my delicates they were way too hot, but it hasn’t always been like this. This is new. What is the most likely scenario here?

Hi Evie, thanks for your question. This issue is commonly caused by a shorted heating element, a restricted ducting system, or a cycling thermostat that has failed. I hope this helps.

1 person found this helpful.

Was this helpful?

Thank you for voting!

John

March 5, 2019

My dryer is making a knocking noise about every 5 rotations or less. What could it be?

For model number MDE7400AYW

Hello John, thank you for your question. We would recommend checking the rollers, belt, idler pulley, felt seals and glides first. I hope this helps!

1 person found this helpful.

Was this helpful?

Thank you for voting!

Stephen

September 17, 2019

You told me yesterday that I would need two fabric washers for the idler pulley. Where does the second one go? On the older shaft before sliding on the pulley?

For model number MDE8757AYW

Hello Stephen, Thank you for the question. The washers will go on each side of the roller. So on one side you will have the retaining ring,washer then roller and the other side you will have the hex nut, washer then roller. Hope this helps!

1 person found this helpful.

Was this helpful?

Thank you for voting!

Shannon

December 3, 2019

Does the idler pulley wheel come with a new shaft? Or is it literally just the wheel?

For model number MDE2500AYW

Hi Shannon,

Thank you for your question. The idler pulley arm and shaft is not sold with the pulley. The part number listed under your model number for the idler arm and shaft is PS11743033. I hope this helps. Thank you and have a great day!

Was this helpful?

Thank you for voting!

Sandra

December 4, 2019

My tension pulley looks like it has a grove in it. My question is is it supposed to or is it broken?

For model number MDE5500AYW

Hello Sandra, thank you for your question. It appears to have a slight groove in it. Over time, a larger groove may appear due to wear. I hope this helps!

Was this helpful?

Thank you for voting!

- < Prev

- 1

- 2

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS11743032

Manufacturer Part Number: WP6-3700340

Manufacturer Part Number: WP6-3700340

Brand

Model Number

Description