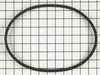

Thrust Washer

$10.14

In Stock

Get this part fast! Average delivery time for in-stock parts via standard shipping: 1.8 days.

PartSelect Number

PS11740482

Manufacturer Part Number

WP233520

Manufactured by

Whirlpool

Product Description

Thrust Washer Specifications

This washer is 3/4 inches in diameter.

How Buying OEM Parts Can Save You Time and Money

Part Videos

Replacing your Amana Dryer Thrust Washer

Troubleshooting

This part fixes the following symptoms:

Noisy | Will not agitate | Burning smell | Spins slowly

This part works with the following products:

Dryer, Washer, Washer Dryer Combo.

This part works with the following products:

Amana, Kenmore, Speed Queen, Whirlpool.

Part# WP233520 replaces these:

AP6007368, 233520, 52549, R0600526, WP52549

Customer Repair Stories

Average Repair Rating: 2.9 / 5.0, 37 reviews.

What's this?

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Drum not centered , clothes getting stuck in dryer

The first thing I did was to unplug the dryer from the wall. Then I removed the bottom two screws and slid the bottom cover off so i could see all the way to the back, I tipped the dryer back against the wall and searched for the problem with a flashlight. I noticed that one of the guide wheels that held the drum in place was sheared off. I took the new drum support roller out and carefully slid it over the shaft, I had to jiggle it around for a bit, but then it finally was seated correctly. I replaced the washer and then the clip using a pair of needle nose pliers and a regular screw driver and then turned the dryer by hand to see if the wheel came off. After confirming that it worked, I put the cover back on, and plugged it in and tested it.

Other Parts Used:

-

Chris from Hopedale, MA

-

Difficulty Level:Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Pliers, Screw drivers

522 of 544 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud banging sound. Worn out roller.

Pulled off the lower panel with 5/16 socket.Pulled off the door assembly by removing the two screws at the bottom of the door assembly. I pulled down a little and then out. be carefull of the wires. Other posts said to remove. The wires were long enough I did not have to remove them. I just leaned it against the wall. I then removed the 4 screws that hold the front piece in.pulled it off replaced brackets , installed self adhesive felt(stuck good) and then glides. Mine were thin but not the problem. I then reached under the drum and released the belt from the tensioner. I then pulled the whole drum out.This is the time to vacum out good. I could get to the rear rollers very easy. The left roller was shot and the shaft half wore into(the problem). I pulled off the two screws holding the roller support. Normally You have to remove the wheel with snap ring pliers first to remove the support. In this case snap ring long gone. Replaced support shaft, installed thrust washers and roller with grease for both sides. The right support shaft was still good. Removed tensioner pulley and inspected. It was just as good as the new one. Cleaned and greased and reinstalled. Put new belt on the tub and slid it back in. Be carefull to get the belt on the proper side of the tensioner. I then installed the front supprt in place to support the tub with the 4 screws. Spun the tub(felt good) then reached under and reinstalled belt to motor and tensioner. Spun again to check for belt alignment. (Check) Reinstalled door an lower panel. Test Quiet Sounds like new. Very easy! I hope this helps someone just as the other post has helped me. Blessings to all.

Other Parts Used:

-

David from Underwood, IA

-

Difficulty Level:Really Easy

-

Total Repair Time:15 - 30 mins

-

Tools:Socket set

163 of 234 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer would squeal when drying clothes

Unplugged dryer, turned off gas, raised front of dryer with two 2X4's on edge resting on legs, removed two lower panel screws, removed lower panel. Removed lower blower & filter assembly, screws (3) are on the inside of drum. (Good chance to clean it out) Removed two lower front upper main panel screws. Supported top panel with wood for access. Removed panel slowly, marked wires that go to door switch, set panel aside. Removed tension on belt by reaching in on the right lower side and unhooking the tensioner from belt, look to see how it is installed, for reinstallation on assembly. Pulled drum out slowly as not to damage seals on drum. replaced parts, attached with self tapping screws.(screws all the same size) reassembly in reverse order. Will need to put belt on drum before installing drum. Check drum alignment with rollers and seals. Used very small amount of high pressure grease on roller bracket and shaft assembly where the support roller shaft spins for lubrication. All's quiet. (Vacuumed out inside while dissassembled)

Other Parts Used:

-

JOHN from CORPUS CHRISTI, TX

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

36 of 42 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Dryer wouldn't rotate the drum.

Removed the screws holding the bottom to the sides (but after taking it all apart, I think I could have done the repair by just taking the front off :-(.

Removed the screws holding the front to the sides. Noted the wiring (three wires go to the front door switch). Removed the wires from the switch (they are quick connects, so no tools necessary). Removed the front. Pull the drum out.

Disconnected the spring from the idler pulley lever. Removed the bolt and nut holding the idler pulley lever assembly to the bottom. (The old pulley had basically frozen in place which caused the belt to break). Put the new washers, wheel assembly and retaining ring on the new idler pulley lever. Bolted it back in place. Connected the spring. Put the new belt around the drum and slid the drum into place. Put the belt around the motor pulley and past the idler wheel (make sure it is on the correct side so this takes up the tension). Put the bottom screws back in. Connected the wires back up to the front. Put the front in place. (Make sure that the drum is properly seated in back so the front goes on and the drum will turn). Put the front screws back on.

Removed the screws holding the front to the sides. Noted the wiring (three wires go to the front door switch). Removed the wires from the switch (they are quick connects, so no tools necessary). Removed the front. Pull the drum out.

Disconnected the spring from the idler pulley lever. Removed the bolt and nut holding the idler pulley lever assembly to the bottom. (The old pulley had basically frozen in place which caused the belt to break). Put the new washers, wheel assembly and retaining ring on the new idler pulley lever. Bolted it back in place. Connected the spring. Put the new belt around the drum and slid the drum into place. Put the belt around the motor pulley and past the idler wheel (make sure it is on the correct side so this takes up the tension). Put the bottom screws back in. Connected the wires back up to the front. Put the front in place. (Make sure that the drum is properly seated in back so the front goes on and the drum will turn). Put the front screws back on.

Other Parts Used:

-

Dan from Newfield, NY

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Screw drivers, Socket set, Wrench set

23 of 607 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Idler pully seperated from bushing

first I unplugged the electrical plug then I removed the lower covet by taking out the 5/16 screws. I then took out the 5/16 screws that hold the top part of the front cover and removed it.

I then worked the belt off the aggitator pully and removed the hoses from the pump. I then used a 1/2 in soclet on long extension th remove the four bolts that hold the motor and pump assembly. I then worked the assembly out of the cabinate and using a long #20 torx bit I removed the pumfrom the housing. I removed the belt, then I removed the housing off the motor and replaced the Idler bracket with the idler pully. I then re-assembled it in the reverse of taking it apart. Works great with the new idler and belt.

David Hilton

I then worked the belt off the aggitator pully and removed the hoses from the pump. I then used a 1/2 in soclet on long extension th remove the four bolts that hold the motor and pump assembly. I then worked the assembly out of the cabinate and using a long #20 torx bit I removed the pumfrom the housing. I removed the belt, then I removed the housing off the motor and replaced the Idler bracket with the idler pully. I then re-assembled it in the reverse of taking it apart. Works great with the new idler and belt.

David Hilton

Other Parts Used:

-

David from Raytown, MO

-

Difficulty Level:Difficult

-

Total Repair Time:More than 2 hours

-

Tools:Nutdriver, Pliers, Socket set

14 of 17 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

High pitched squealing noise for about 5 minutes when I first turned the dryer on. As the problem worsened, the squealing became more prevalent and annoying.

Removed the two sheet metall screws on the front foot panel, removed the four screws holding the door assembly, wrote down the wiring placement for the front door, removed the blower bulkhead assembly by removing one screw in the bottom of the dryer. Removed two screws and propped the dryer top panel up at a 45 degree angle to gain additional clearance. Removed the drum and belt from the front and back seals by applying simple outward pressure. Removed the screw in the bottom of the motor assembly allowing me to reposition the assembly for easy access. Removed bolt holding old Idler arm assembly. Assembled new Idler pulley referring to old assembly. Reversed the process to complete the repair. Note: I found it easier to simply hang the dryer belt over the dryer drum when replacing the drum in the dryer. First you need to place and align the drum then route the belt back to the moter pulley and then over the idler pulley. if you try to put the belt over the motor and then align the drum, it is difficult to keep the belt on the pulley. It might help to draw a diagram of the belt route or obtain the belt route diagram from the website for reference. Very easy job.

Other Parts Used:

-

Jim from Frisco, TX

-

Difficulty Level:Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Wrench set

14 of 19 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Loud sreeching and vibration

I just followed the videos I received with the order and everything went really well. This dryer was a little different than the video, but the process was the same. The HE3 does require 4 drum rollers and I had only ordered 2. However, there was only one bad roller, so I installed both on the back of the drum. The two front rollers are pretty easy to get to if they go bad. The idler pulley was completely worn out with an 1/8 inch groove worn off to one side. PartSelect made this an easy project!

Other Parts Used:

-

Robert from TUTTLE, OK

-

Difficulty Level:Really Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers

13 of 14 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Squeak and slight burning smell during spin cycle.

I took off the lower front panel and “watched” with a flashlight during the spin cycle. I could see that the idler pulley was intermittently stopping and starting. The back of the drive belt was also worn in the center. When the idler pulley was moving, it squeaked, when it didn’t, the friction wore the belt and made the smell.

To replace the Idler Pulley Wheel:

1. Take off the lower and upper front panels to access the motor assembly.

2. Remove motor by loosening four bolts.

3. Remove spring that applies tension to the idler pulley.

4. Remove the electrical connector by squeezing the plastic tab on top.

5. Remove hoses by gripping clamps with pliers (put down rags first to catch water)

6. Unhook belt from tub pulley

7. Remove 1 cabinet spring to make it easier to remove motor

8. Remove motor.

9. Remove allen screws holding the pump to the motor

10. Remove the pump and belt (take note of the location of the belt before removing).

11. Remove retaining ring to replace Idler Pulley Wheel (this was probably the trickiest part; I used a very tiny needle nose pliers and straight screwdriver).

12. Replace the washers on either side of the Idler Pulley Wheel as well as the retaining ring.

13. Replace belt.

14. Reassemble in reverse order.

15. Be thankful for the money you saved on a service call.

To replace the Idler Pulley Wheel:

1. Take off the lower and upper front panels to access the motor assembly.

2. Remove motor by loosening four bolts.

3. Remove spring that applies tension to the idler pulley.

4. Remove the electrical connector by squeezing the plastic tab on top.

5. Remove hoses by gripping clamps with pliers (put down rags first to catch water)

6. Unhook belt from tub pulley

7. Remove 1 cabinet spring to make it easier to remove motor

8. Remove motor.

9. Remove allen screws holding the pump to the motor

10. Remove the pump and belt (take note of the location of the belt before removing).

11. Remove retaining ring to replace Idler Pulley Wheel (this was probably the trickiest part; I used a very tiny needle nose pliers and straight screwdriver).

12. Replace the washers on either side of the Idler Pulley Wheel as well as the retaining ring.

13. Replace belt.

14. Reassemble in reverse order.

15. Be thankful for the money you saved on a service call.

Other Parts Used:

-

Jim from Swanton, OH

-

Difficulty Level:Easy

-

Total Repair Time:1- 2 hours

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

13 of 15 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Washe would not spin clothes or agitate well

Pulled motor, as the belt will not come off unless you take to water pump off off the motor. Installed new idler wheel, washers, clips and belt. Reinstalled motor.

Works good and hopefully lasts a long time!

Works good and hopefully lasts a long time!

Other Parts Used:

-

Berry from Mt Sidney, VA

-

Difficulty Level:A Bit Difficult

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Screw drivers, Socket set

8 of 11 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

Noisy drum support rollers

1-Unplugged drier

2-removed lower panel-(2)-8mm screws

3-removed intake from fan-(3)-8mm screws

4-removed dryer's front panel-w/door assembly-(2)-8mm screws. (note there is a door switch you will need to disconnect the wires and remember which terminals they go to.

5-remove the front drum support-(4)-8mm screws

***** at this point the drum is exposed *****

6-reached under the drum pulled the tensioner to relieve tension on belt, then dismounted the belt from only the tensioner and motor shaft; leave the belt on the drum!

7-pull drum toward you and forward about 3-to-4 inches, this exposes the drum rollers.

8-use a screwdriver and pry-off the retaining clip on the end of the roller's shaft and remove the roller.

9-remove the roller support-(2)-8mm screws

10- reinstall new roller support

11- apply a light coat of disc-brake hi-temp wheel bearing grease to the roller support shaft, very light!

12-install a new wavy thrust washer, new roller(note they will say "front" on the side that should face you. Don't mount it backwards!

13-install the outer thrust washer and the new retaining clip; use a flashlight for this part!

14-repeat for the other drum roller.

**** while you have it apart use a vacuum to remove lint from every where you see it; it is a fire hazard!

**** if you think you need a drive belt now is the best time to change it *****

15- re-assemble the dryer in the reverse order, don't forget to re-install the drive belt and be careful not to pinch the door switch wires.

16-re-plug the drier and test

2-removed lower panel-(2)-8mm screws

3-removed intake from fan-(3)-8mm screws

4-removed dryer's front panel-w/door assembly-(2)-8mm screws. (note there is a door switch you will need to disconnect the wires and remember which terminals they go to.

5-remove the front drum support-(4)-8mm screws

***** at this point the drum is exposed *****

6-reached under the drum pulled the tensioner to relieve tension on belt, then dismounted the belt from only the tensioner and motor shaft; leave the belt on the drum!

7-pull drum toward you and forward about 3-to-4 inches, this exposes the drum rollers.

8-use a screwdriver and pry-off the retaining clip on the end of the roller's shaft and remove the roller.

9-remove the roller support-(2)-8mm screws

10- reinstall new roller support

11- apply a light coat of disc-brake hi-temp wheel bearing grease to the roller support shaft, very light!

12-install a new wavy thrust washer, new roller(note they will say "front" on the side that should face you. Don't mount it backwards!

13-install the outer thrust washer and the new retaining clip; use a flashlight for this part!

14-repeat for the other drum roller.

**** while you have it apart use a vacuum to remove lint from every where you see it; it is a fire hazard!

**** if you think you need a drive belt now is the best time to change it *****

15- re-assemble the dryer in the reverse order, don't forget to re-install the drive belt and be careful not to pinch the door switch wires.

16-re-plug the drier and test

Other Parts Used:

-

Remy from Santa Maria, CA

-

Difficulty Level:Really Easy

-

Total Repair Time:30 - 60 mins

-

Tools:Nutdriver, Pliers, Screw drivers, Socket set

6 of 7 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

Questions and Answers

Ask our experts a question about this part and we'll get back to you as soon as possible!

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Shane

July 30, 2018

My washer won’t spin out the water in either cycle / took the back cover off and watched the action / belt seemed tight but it didn’t have spin fast enough to pull the water out of tub/ the belt is a: 8540101 hutchinson poly-v 6 pje 1304 ej 176>br,cr< isol clz

For model number NFW 7300WW00

Hello Shane, Thank you for the email. If the belt is good and tight, I suggest testing the drive motor, PartSelect Number PS11749532. You'll want to test from pin 1 to 2, 2 to 3 and 1 to 3, looking for 6 ohms or matching readings. If one is either too high or low you have a bad winding and will need to replace the motor. Hope this helps!

4 people found this helpful.

Was this helpful?

Thank you for voting!

- < Prev

- 1

- Next >

✖

Ask a Question

Ask our experts a question on this part and we'll respond as soon as we can.

Sorry, we couldn't find a match for "".

Here's a guide for finding your model number.

Something went wrong. Please try again later.

Your Question Has Been Submitted!

Our experts will send you an email as soon as your question has been answered.

Related Parts

Model Cross Reference

This part works with the following models:

PartSelect Number: PS11740482

Manufacturer Part Number: WP233520

Manufacturer Part Number: WP233520

Brand

Model Number

Description