After new belt, load dry bearing sound in spin cycle and brake squeal. Videos were very helpful, but limited. Thinking with new belt pulling pressure, it had to be bearings. Top bearing I was worried of possible water seal being disturbed ? 1 * Not so, the big top bearing sits alone under brake housing, but spent most time prying off with a wheel puller. Need like 10inch reach for puller. Has a plastic housing around it, that you have to pry on, but no damage seemed evident when done. This was the worse part ! 2 * Pulled springs, (with vise grips) water level hose,(fingers) and pump hose,(pliers and twist to free) removed motor (two 1/2 inch bolts and wires), then v belt. Tub/transmission all pulled out easy with front cover removed already. 3* Inverted, pop plastic cover, pry spring clip with screwdriver,(a little stubborn) and pulley pulls out easy. Now look good at the pulley inner part, it has to be adjusted when done, and instructions are not that clear. So here I will try to give a better clue. The instruction sheet shows the outer ring part with small inner space to tabs, and a bigger space to tabs. The larger 2/3 tab swing space is the control setting area.. Inner part swings left and right around to the tabs, A small 1/3 area, and bigger 2/3 area. Looking at the large side, the outer ring has two exterior raised notch of plastic. If you twist the pulley CW looking down, until it hits the first left tab, this would be the start point for adjusting. Instructions state, the first outer notch is the "MIN" point, and the next notch (about an inch away) is the "MAX" point. When reassembling and WITH the washer &clip in the groove (use the old one and just push one side into the goove to temporary hold center shaft in place) Key is the pulley has to be turned CW, and needs the clip to hold shaft, as pressure is put on the lower brake spring. OK, clip holding, CW turn pulley until the left tab stop is hit, now slowly turn pulley CCW and watch when the shaft starts turning. Plastic inner part has a 3-d arrow formed in it close to the first exterior notch. Setting is to turn the CCW direction with the arrow moving in between the MIN /Max outer notch, before the shaft start to turn. Ideally in the middle of the two exterior notches. Instructions state this, but never said the clip had to be in place ! What happens is CW releases the brake spring for the brake on, CCW applies preasure to unlock the brake, and that should be about the middle of the notches on outer side of ring, when the shaft starts to turn. Two washers are with pulley/bearing kit, one is used depending oh where the middle arrow starts to turn shaft. Apply the grease as instructed. 4 * Brake use of three 10/24 bolts worked well, described by other reviews. Spring is 200 lb. rating, so an adult can push down for most of the movement. The screw turned out easy, and reassembly by pushing down some pressure and screwing in faster saves time. It is the distance of about 1.5x oem screw size that the spring preasure gets hard, so then just keep turning the screws 2-4 turns each, to press back into place. First brake cover plate was totally glazed at brake pad area. I replaced it, but could have possible just sanded it some. Next lower brake pad disc, showed lots of brake pad, Replaced it to since I bought the parts, but maybe just sanding a little would have been good too. 5 * If you pull the two brake parts out, underneath is the upper bearing that was the hard thing to pull off. Start Access by removing the three screws under the brake, and then the outer metal ring support screws.( set of three/two screws. 9/16 inch). Pull cover off and here is the big top bearing with the plastic support housing under it, with no room to move it away. A couple drops of oil in the inner ring, and wheel puller use, the bearing started to slide off easy abut half way off. 6 * All this done and my snubber ring was showing wear, so good idea I bought the new snubber ring and all six tub springs. 7 * Tub springs are a little tough, vise grips, wiggle yourself into position, and do the rear ones first. My washer had all the springs inserted CCW position, spring inserted into base on left side hole that is oval. A little grease on spring bottom loop as per video. 8 * Long story, easy two hours plus, but took my time, brake squeal is gone, tub seems a little less wobble in spin cycle, but still sounds like a dry bearing ! Now starting to think it is the motor bearings just transmitting the sound up the tub like a megaphone ? OEM bearings did not seem worn enough to be an issue. Top bearing is a standard ball bearing, and lower bearing is a thrust roller bearing. Parts so far cost almost half the price of a new washer ! Best of luck, tried to clear up some "what issues" !

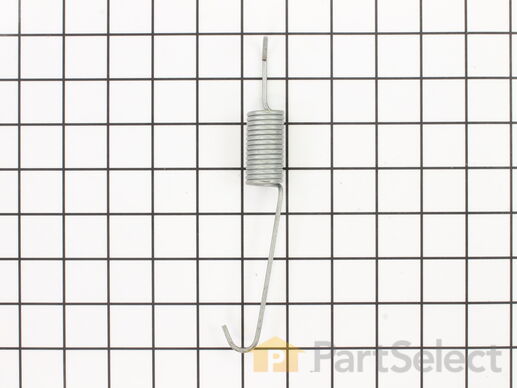

Other Parts Used: